High-fiber dried egg and preparation method thereof

A technology of high-fiber eggs and dried eggs, which is applied in food science and other fields, can solve the problems of large nutritional loss, product nutritional loss, and poor taste, and achieve the effect of good tissue toughness, high yield, and Q-bomb taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: A kind of preparation method of high-fiber dried egg product

[0053] Product formula: 70 parts of whole egg liquid, 10 parts of tissue protein, 1 part of compound phosphate, 5 parts of white sugar, 10 parts of polydextrose, 5 parts of casein, 1 part of edible salt, 0.5 parts of monosodium glutamate, 1 part of spices, 1.5 parts of soy sauce parts, TG enzyme 0.3 parts.

[0054] Process steps:

[0055] 1. Pretreatment of raw materials; frozen whole egg liquid, thawed at 0-4°C for later use; soybean tissue protein needs to be rehydrated in advance until there is no hard core and dehydrated, and then disassembled by a wire dismantling machine for later use.

[0056] 2. Ingredients: take whole egg liquid and other raw and auxiliary materials respectively according to the above-mentioned formula ratio;

[0057]3. Stirring: Add the powder into the egg liquid, and stir until there are no particles, then add other liquid ingredients and stir to mix well to prepar...

Embodiment 2

[0064] Embodiment 2: the selection of soybean textured protein addition amount

[0065] With reference to the formula described in Example 1, the difference is that the amount of textured soybean protein adjusted is respectively 0, 5, 20, 30, 40 parts, and other conditions are the same as in Example 1.

[0066] Table 2 Effect of different amount of tissue protein added on texture

[0067]

Embodiment 3

[0068] Embodiment 3: the selection of pH

[0069] With reference to the method described in Example 1, the difference is that the adjusted pH value is respectively 2, 6, 9, and 12, and other conditions are the same as in Example 1. The results show that in the weakly alkaline environment of pH 7.5, the crosslinking strength and cohesion of the final dried egg are the best in the experimental group, indicating that the pH is too high or too low will affect the release of the polypeptide site of the silk protein And the efficiency of TG enzyme. Therefore, preferably, the pH is 7.5.

[0070] Table 3 Effect of different pH on texture

[0071]

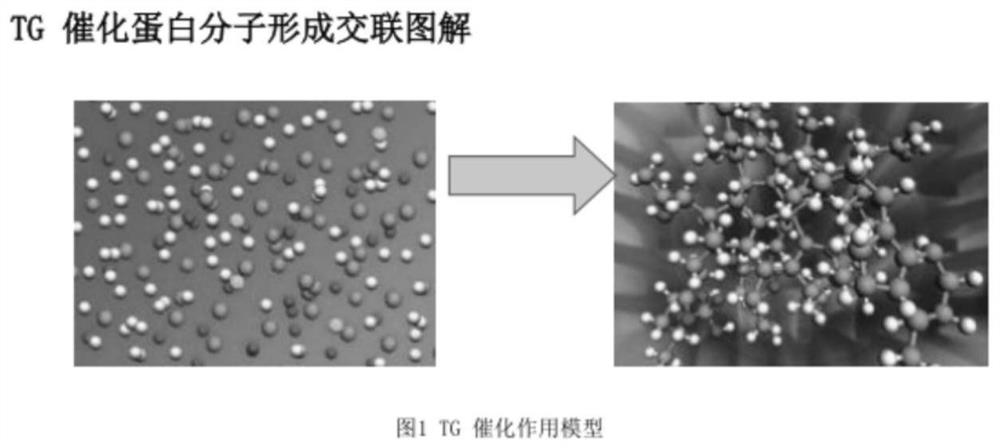

[0072] During the enzyme reaction treatment, the condensed protein polypeptide sites in the textured protein are exposed and released by adjusting the pH and ultrasonic treatment, so that TG enzyme can catalyze the intramolecular and intermolecular isopeptides formed in the protein molecules of tissue protein and egg protein Bonds / cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com