Preparation method of special-effect high-moisture emulsion

A moisturizing lotion and special effect technology, which is applied in skin care preparations, pharmaceutical formulas, cosmetic preparations, etc., can solve the problems of limited moisturizing effect and single function, and achieve the effect of improving moisturizing ability, nourishing skin, and inhibiting cell aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

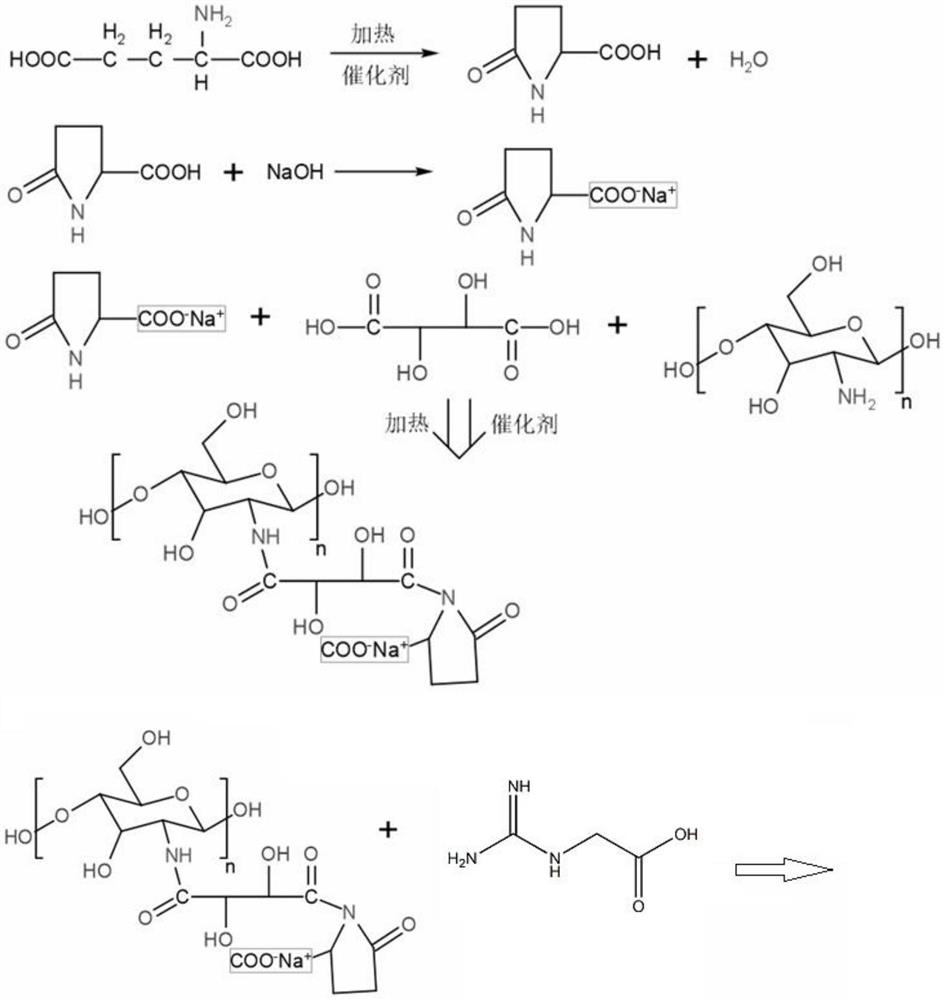

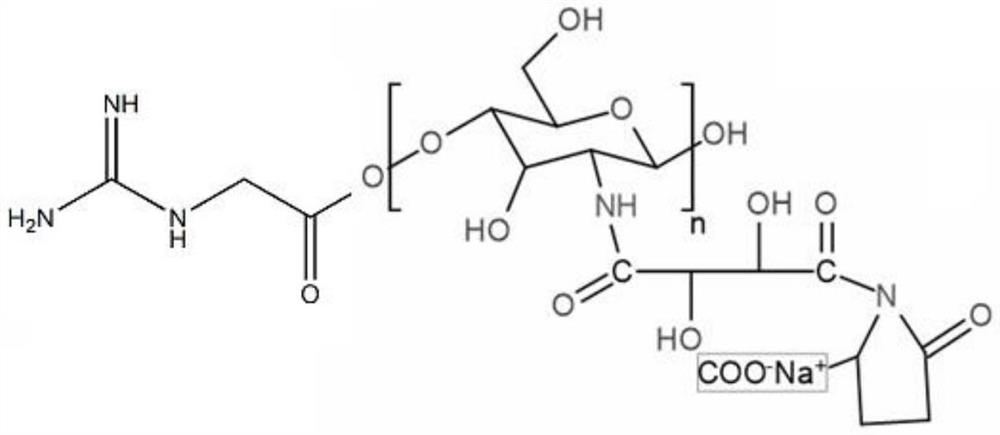

Method used

Image

Examples

Embodiment 1

[0038] Step 1, 1g cetyl alcohol, 5g olive oil, 8g paraffin oil, 1gC10 triglyceride, 1g methyl glucoside polypropylene glycol-20 ether distearate, 0.5g wheat germ oil, 1g octyldodecanoate Alcohol is added to container A and heated to 75 ℃ , stirred at 100r / min for 40min to obtain mixed solution A;

[0039]Step 2, add 0.2g vitamin A, 0.01g hyaluronic acid, 2g β-glucan, 0.1g allantoin, 0.5g self-made moisturizer, 100g deionized water into container B, heat to 85 ℃ , stirring at 100r / min for 40min, then cooling down to 75 ℃ , to obtain the mixed solution B;

[0040] Step 3, add the mixed solution B into the vacuum homogenization tank, then slowly add the mixed solution A to the mixed solution B stirred at 50r / min, and control the temperature to 70 ℃ , then homogeneously emulsified at a speed of 500r / min for 10min, stirred at a speed of 50r / min, and cooled to 35 ℃ , to obtain a pre-emulsion;

[0041] Step 4, add 0.05g dandelion alcohol and 0.2g Eupatorium essence to the pre-em...

Embodiment 2

[0046] Step 1, 1.8g cetyl alcohol, 5.7g olive oil, 8.6g silicone oil, 2.4g C10 triglyceride, 1.3g methyl glucoside polypropylene glycol-20 ether distearate, 0.6g wheat germ oil, 1.4 g octyldodecanol was added to container A and heated to 79.6 ℃ , stirred at 130r / min for 32.6min to obtain mixed solution A;

[0047] Step 2, add 0.3g vitamin B5, 0.03g hyaluronic acid, 2.4g aloe extract, 0.1g allantoin, 0.6g self-made moisturizer, 108.6g deionized water into container B, heat to 89.6 ℃ , stirring at 140r / min for 34.6min, then cooling down to 78 ℃ , to obtain the mixed solution B;

[0048] Step 3, add the mixed solution B into the vacuum homogenization tank, then slowly add the mixed solution A to the mixed solution B stirred at 70r / min, and control the temperature to 73 ℃ , then homogeneously emulsified at a speed of 700r / min for 6.9min, stirred at a speed of 70r / min, and cooled to 38.3 ℃ , to obtain a pre-emulsion;

[0049] Step 4, add 0.06g sesquiterpene lactone and 0.2g st...

Embodiment 3

[0054] Step 1, 2.4g cetyl alcohol, 7g olive oil, 9.3g cholesterol, 3.1gC10 triglyceride, 1.6g methyl glucoside polypropylene glycol-20 ether distearate, 0.7g wheat germ oil, 1.6g Add octyldodecanol to container A and heat to 82.6 ℃ , stirred at 160r / min for 27.9min to obtain mixed solution A;

[0055] Step 2, add 0.5g vitamin C, 0.06g hyaluronic acid, 2.7g trehalose, 0.2g allantoin, 0.8g self-made moisturizer, 117.9g deionized water into container B, heat to 91.6 ℃ , stirred at 170r / min for 31.2min, then cooled down to 79.6 ℃ , to obtain the mixed solution B;

[0056] Step 3, add the mixed solution B into the vacuum homogenization tank, then slowly add the mixed solution A to the mixed solution B stirred at 85r / min, and control the temperature to 77 ℃ , then homogeneously emulsified at a speed of 850r / min for 5.5min, stirred at a speed of 85r / min, and cooled to 42.6 ℃ , to obtain a pre-emulsion;

[0057] Step 4, add 0.07g cassia alcohol and 0.2g aromatic herb oil to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com