Method for preparing polyaluminium sulfatochloride water treatment agent

A technology of aluminum chloride sulfate and water treatment agent, applied in water/sewage treatment, chemical instruments and methods, adsorbed water/sewage treatment, etc., can solve the problems of unsatisfactory flocculation effect, complicated preparation process, poor product stability, etc. To achieve the effect of improving flocculation effect, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

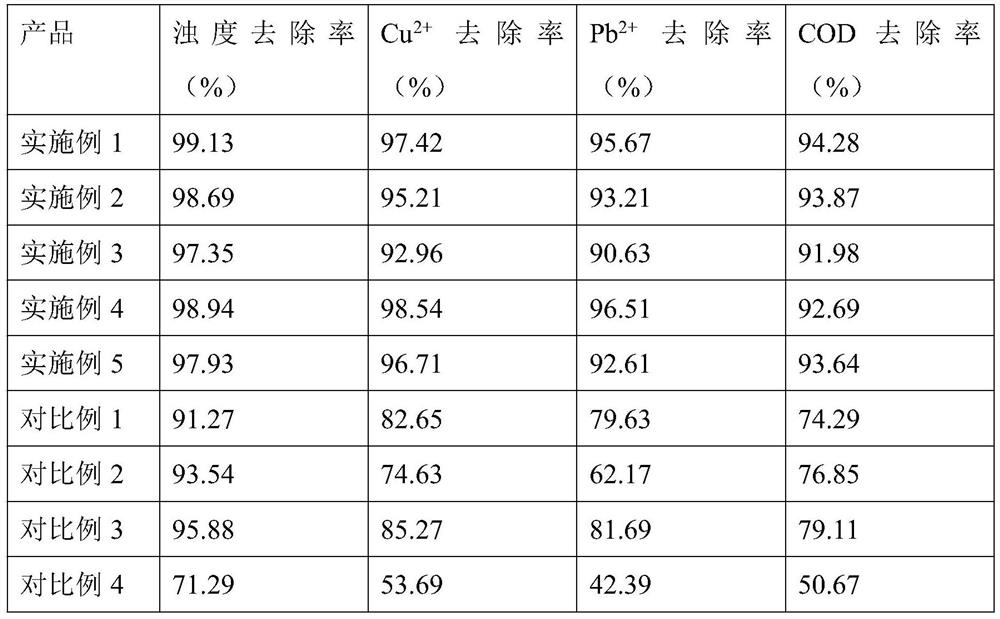

Examples

Embodiment 1

[0023] A method for preparing polymeric aluminum chloride water treatment agent, comprising the steps:

[0024] (1) According to the following weight ratio, 13 tons of aluminum hydroxide and 18 tons of hydrochloric acid were reacted at 135°C and 0.5MPa high temperature and high pressure for 3h to obtain aluminum chloride liquid;

[0025] (2) Add 12 tons of aluminum sulfate liquid and 16 tons of water to the aluminum chloride liquid and react for 1.5h at a temperature of 80 ° C, then add polyethylene glycol 60030kg and cetyltrimethylammonium bromide 35kg at the temperature To react at 100 ° C for 1 h to obtain a mixed solution of aluminum sulfate chloride;

[0026] (3) 70kg of chitosan was added to the aluminum sulfate chloride mixed solution, heated to 60°C and stirred for 40min, then filtered by pressure, and dried with supercritical fluid, and the drying took carbon dioxide as a drying medium at a temperature of 40°C , and drying under the pressure of 8MPa to obtain a water...

Embodiment 2

[0029] A method for preparing polymeric aluminum chloride water treatment agent, comprising the steps:

[0030] (1) According to the following weight ratio, 10 tons of aluminum hydroxide and 16 tons of hydrochloric acid were reacted at 140°C and 0.4MPa high temperature and high pressure for 2.5h to obtain aluminum chloride liquid;

[0031] (2) Add 14.5 tons of aluminum sulfate liquid and 18 tons of water to the aluminum chloride liquid and react for 2 h at a temperature of 70 ° C, then add 60020 kg of polyethylene glycol and 30 kg of cetyltrimethyl ammonium bromide at a temperature of The reaction was carried out at 120 °C for 1.5 h to obtain a mixed solution of aluminum sulfate chloride;

[0032] (3) 60kg of chitosan was added to the aluminum sulfate chloride mixed solution, heated to 60°C and stirred for 40min, then filtered by pressure, and dried with supercritical fluid, and the drying took carbon dioxide as a drying medium at a temperature of 50°C , and drying under the ...

Embodiment 3

[0035] A method for preparing polymeric aluminum chloride water treatment agent, comprising the steps:

[0036] (1) According to the following weight ratio, 14 tons of aluminum hydroxide and 20 tons of hydrochloric acid were reacted at 140° C. and 0.5MPa high temperature and high pressure for 3.5h to obtain aluminum chloride liquid;

[0037] (2) Add 12 tons of aluminum sulfate liquid and 17 tons of water to the aluminum chloride liquid and react for 1.5h at a temperature of 80°C, then add 60045kg of polyethylene glycol and 25kg of cetyltrimethylammonium bromide at a temperature of 80°C. The reaction was carried out at 110 °C for 2 h to obtain a mixed solution of aluminum sulfate chloride;

[0038] (3) 50kg of chitosan was added to the aluminum sulfate chloride mixed solution, heated to 70°C and stirred for 60min, then filtered by pressure and dried with supercritical fluid, and the drying took carbon dioxide as a drying medium at a temperature of 60°C , and drying under the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com