A method for preparing super slippery antifouling surface by grafting lubricating oil with modified hollow microspheres

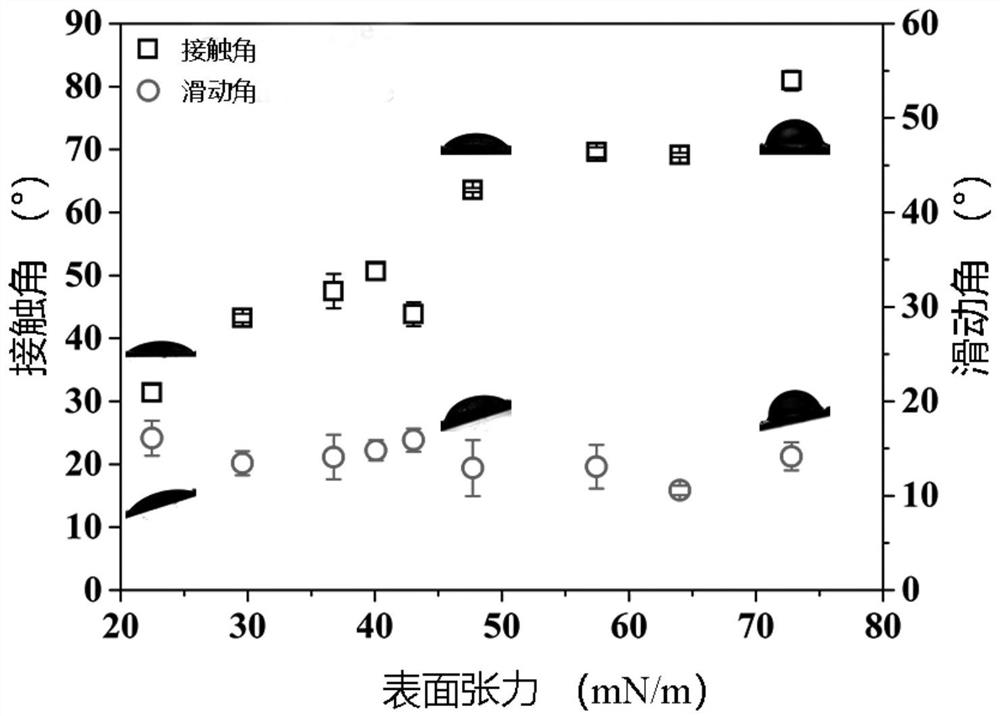

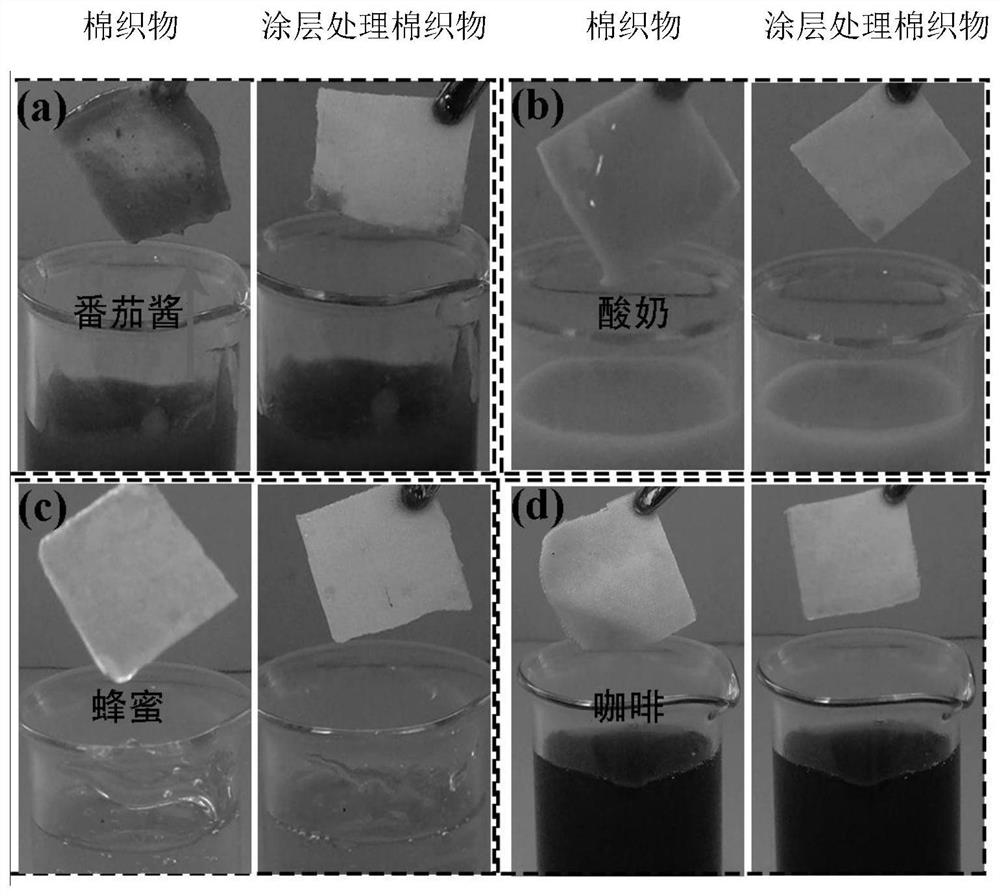

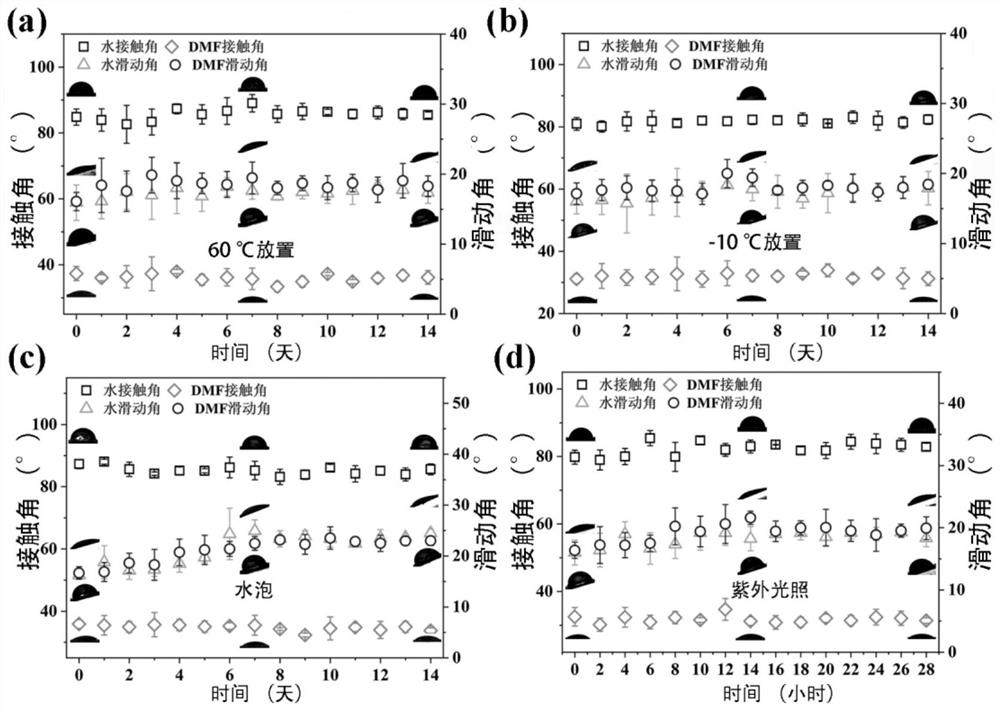

A lubricating oil and modification technology, which is applied to the surface coating liquid device, pretreatment surface, anti-fouling/underwater coating, etc., can solve the problem that the wicking effect of lubricating oil cannot ensure that the holes are completely filled and the oil storage capacity on the surface Small, the combination fastness between lubricating oil and substrate needs to be improved, etc., to achieve good self-healing performance, improved stability, good liquid repellency and antifouling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A method for preparing a cotton fabric with an ultra-slip antifouling surface, comprising the steps of:

[0066] (1) Add 10g of styrene, 2.5g of polyvinylpyrrolidone K30, and 100mL of water into a 250mL three-necked flask, and stir for 30min under nitrogen at room temperature; then add 0.41g of azobisisobutylamidine hydrochloride, Under stirring reaction 24h, obtain polystyrene emulsion;

[0067] (2) Dissolve 1.5g of tetraethyl orthosilicate, 1.31g of cetyltrimethylammonium bromide and 7mL of polystyrene emulsion in 40mL of absolute ethanol, add 1mL of ammonia water, mix and stir, and react at 50°C for 3h. After three times of centrifugal washing and drying, silica-coated polystyrene microspheres (PS@SiO 2 ); PS@SiO 2 Calcined in a muffle furnace at 500°C±5°C for 3h to obtain hollow mesoporous silica nanoparticles (HMS); the particle size of the silica is 280±3.8nm, and the shell thickness is 30±4.6nm;

[0068] (3) 1g of HMS and 5g of 3-mercaptopropyltriethoxysilane ...

Embodiment 2

[0077] A method for preparing a copper sheet with an ultra-slippery antifouling surface, comprising the steps of:

[0078] (1) Add 10g of styrene, 2.5g of polyvinylpyrrolidone K60, and 100mL of water into a 250mL three-neck flask, and stir for 30min at room temperature with nitrogen gas; then add 0.41g of ammonium persulfate, and stir and react at 70°C for 24h to obtain polystyrene emulsion;

[0079] (2) Dissolve 1.5g of tetraethyl orthosilicate, 1.31g of cetyltrimethylammonium bromide and 7mL of polystyrene emulsion in 40mL of absolute ethanol, add 1mL of ammonia water, mix and stir, and react at 50°C for 3h. PS@SiO was obtained after centrifugal cleaning three times and drying 2 ;PS@SiO 2 Calcined at 500°C±5°C for 3h in a muffle furnace to obtain hollow mesoporous silica nanoparticles (HMS); the particle size of the silica is 277±7.1nm, and the shell thickness is 28±3.8nm

[0080] (3) 1g of HMS and 5g of vinyltriethoxysilane are uniformly dispersed in 44g of absolute etha...

Embodiment 3

[0084] A method for preparing glass with an ultra-slip antifouling surface, comprising the steps of:

[0085] (1) Add 10g of styrene, 2.5g of polyvinylpyrrolidone K30, and 100mL of ethanol into a 250mL three-necked flask, and stir for 30min under nitrogen at room temperature; then add 0.41g of azobisisobutyronitrile, and stir the reaction at 70°C 24h, obtain polystyrene emulsion;

[0086] (2) Dissolve 1.5g of tetraethyl orthosilicate, 1.31g of cetyltrimethylammonium bromide and 7mL of polystyrene emulsion in 40mL of absolute ethanol, add 1mL of ammonia water, mix and stir, and react at 50°C for 3h. PS@SiO was obtained after centrifugal cleaning three times and drying 2 ; will PS@SiO 2 Calcined in a muffle furnace at 500°C±5°C for 3h to obtain hollow mesoporous silica nanoparticles (HMS); the particle size of the silica is 288±3.2nm, and the shell thickness is 26±4.6nm;

[0087] (3) Disperse 1g of HMS and 5g of 3-glycidyloxypropyltrimethoxysilane evenly in 44g of absolute et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com