External compression air separation technological process with energy storage, power generation and substance recovery functions

A technological process and compressed air technology, applied in the field of air separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

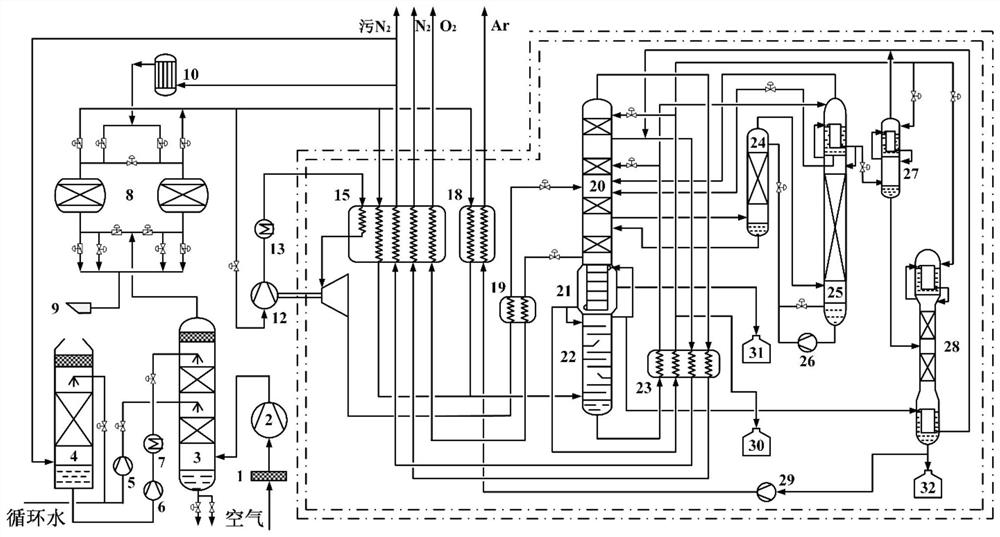

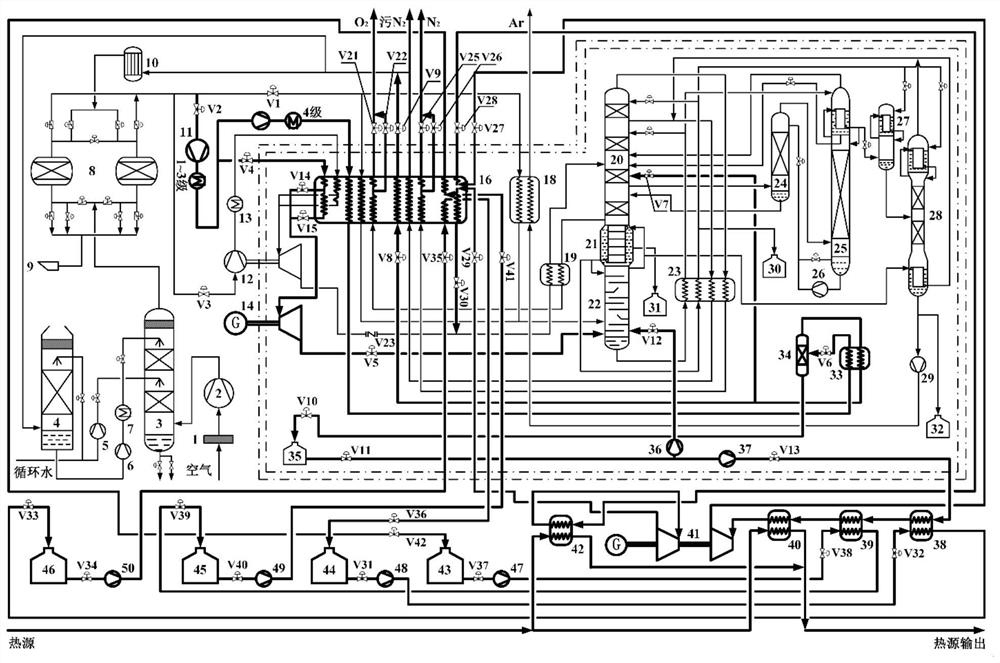

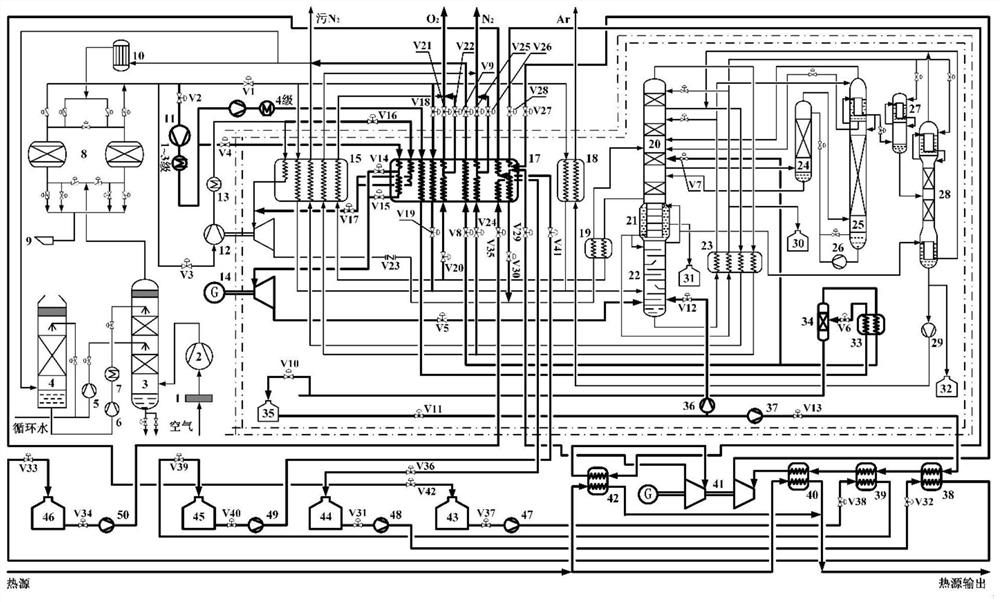

[0042] like figure 2 Shown is the oxygen production 40000Nm in the embodiment of the present invention 3 h -1 Schematic diagram of the air separation external compression process with the functions of energy storage, power generation and material recovery, replacing the medium-pressure main heat exchanger. During valley power storage, the raw air passes through the air filter 1 to remove dust and then enters the air compressor 2 for compression, and then enters the air cooling tower 3 for cooling and washing. The water used for cooling the air in the air cooling tower 3 has two parts: one part is for cooling The circulating water is pressurized by the cooling water pump 5 and sent to the middle part of the air cooling tower 3; the other part is chilled water, the circulating cooling water is initially cooled in the water cooling tower 4 by the dry dirty nitrogen and nitrogen from the rectification system, and then refrigerated The water pump 6 pressurizes, and is sent to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com