Special high-toughness carbon fiber composite core rod for power transmission wire

A technology for transmission wires and composite mandrels, applied to power cables including optical transmission components, conductive materials dispersed in non-conductive inorganic materials, conductors, etc. Rod brittleness and other problems, to achieve the effect of low line cost, small sag, and large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

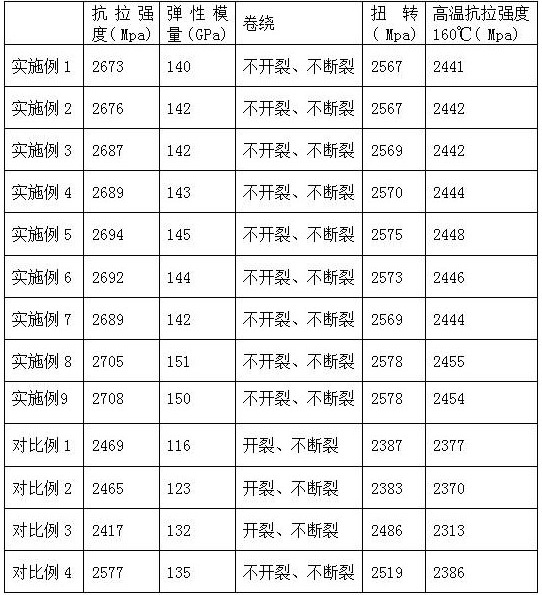

Examples

Embodiment 1

[0022] A special high-toughness carbon fiber composite mandrel for power transmission wires, made of the following raw materials in parts by weight: 35 parts of polyacrylonitrile-based carbon fiber, 5 parts of glass fiber, 7 parts of sisal fiber, 18 parts of epoxy resin, and 9 parts of curing agent 1.5 parts of liquid silicone rubber, 2.5 parts of filler, 1.2 parts of coupling agent, 250 parts of styrene.

[0023] The carbon content of the polyacrylonitrile-based carbon fiber is 92%. The curing agent is curing agent 703. The coupling agent is silane coupling agent KH550. The filler is silicon nitride.

Embodiment 2

[0025] A special high-toughness carbon fiber composite mandrel for power transmission wires, made of the following raw materials in parts by weight: 36 parts of polyacrylonitrile-based carbon fiber, 6 parts of glass fiber, 8 parts of sisal fiber, 20 parts of epoxy resin, and 10 parts of curing agent 1.6 parts of liquid silicone rubber, 3 parts of filler, 1.3 parts of coupling agent, 253 parts of styrene.

[0026] The carbon content of the polyacrylonitrile-based carbon fiber is 93%. The curing agent is curing agent 704 . The coupling agent is silane coupling agent KH550. The filler is nano titanium dioxide.

Embodiment 3

[0028] A special high-toughness carbon fiber composite mandrel for power transmission wires, made of the following raw materials in parts by weight: 37 parts of polyacrylonitrile-based carbon fiber, 7 parts of glass fiber, 9 parts of sisal fiber, 21 parts of epoxy resin, and 10.5 parts of curing agent Parts, 1.7 parts of liquid silicone rubber, 3.5 parts of filler, 1.4 parts of coupling agent, 255 parts of styrene.

[0029] The carbon content of the polyacrylonitrile-based carbon fiber is 94%. The curing agent is curing agent 781. The coupling agent is silane coupling agent KH551. The filler is calcium carbide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com