A ternary cathode material with low gas production and high capacity

A cathode material and substrate technology, which is applied in the field of electrochemistry, can solve the problems of intensified side reactions between cathode active materials and electrolytes, reduced reversible gram capacity of active materials, and deteriorated gas production performance at high temperature, so as to improve thermal stability and production. Gas phenomenon, good crystal structure stability, the effect of suppressing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The third aspect of the present invention provides the preparation method of the cathode material provided by the first aspect of the present invention, comprising:

[0039] Provide the substrate;

[0040] A cladding layer is formed on the surface of the substrate.

[0041] The preparation method of the positive electrode material provided by the present invention may include: providing a substrate. The method for providing the base material should be known to those skilled in the art, for example, it may include: mixing and sintering the raw materials of the base material to provide the base material. Those skilled in the art can select appropriate raw materials and proportions of the substrate according to the elemental composition of the substrate. For example, the raw materials of the substrate may include ternary material precursors of nickel, cobalt, manganese and / or aluminum, sources of lithium, sources of M, sources of Me, sources of A, etc., and the ratio of ...

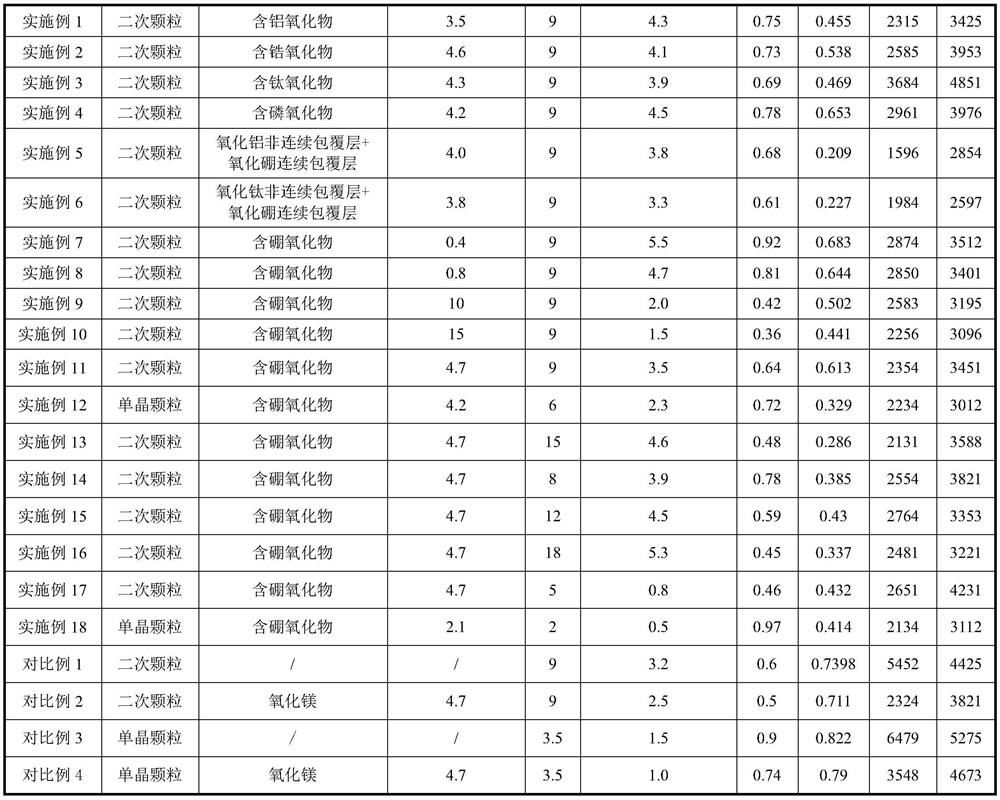

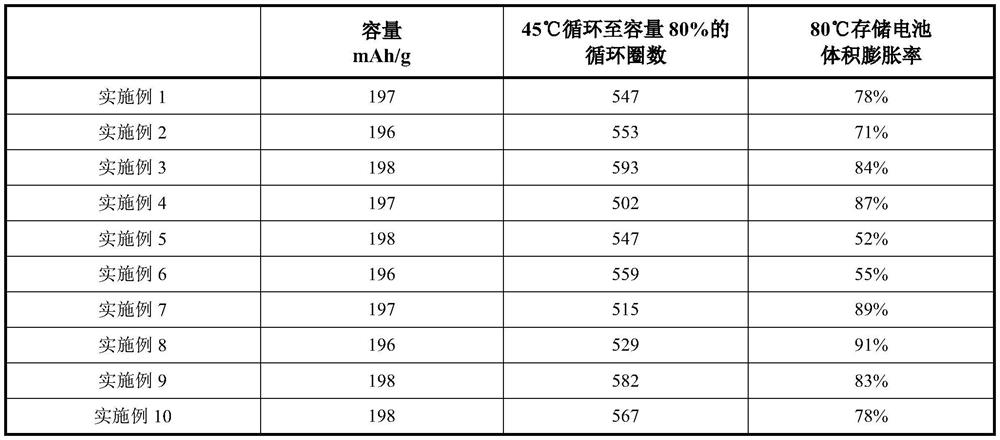

Embodiment 1

[0056] (1) The specific preparation process of the positive electrode material is:

[0057] a. Preparation of substrate precursor:

[0058] Nickel sulfate, manganese sulfate, and cobalt sulfate are formulated into a solution with a concentration of 1mol / L according to the molar ratio of Ni:Co:Mn of 8:1:1, and lithium nickel with a larger particle size is prepared by using hydroxide co-precipitation technology. Precursor Ni of transition metal oxide A 0.8 co 0.1 mn 0.1 (OH) 2 . In the process of preparing the precursor, the reaction time is 75h-125h, the pH value during co-precipitation is 7.5-8.5, and the ammonia concentration is 1mol / L.

[0059] b. Preparation method of cathode material:

[0060] The ternary material precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 and LiOH·H 2 O is placed in a mixing equipment for mixing, and then placed in an atmosphere furnace for sintering at 800 ° C. After cooling, it is mechanically ground to become the base material of the ternary mate...

Embodiment 2

[0074] The preparation method of the positive electrode material is basically the same as in Example 1, except that the coating additive is zirconia, and the content of the coating element is 4.6mg / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com