Solid-state lithium air battery

An air battery and solid-state lithium technology, applied in secondary batteries, solid electrolytes, circuits, etc., can solve the problems of reducing the energy density of lithium-air batteries, it is difficult to build a three-phase interface, and lithium-air cannot be used to achieve safety. Improves, inhibits lithium dendrites, and prolongs service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

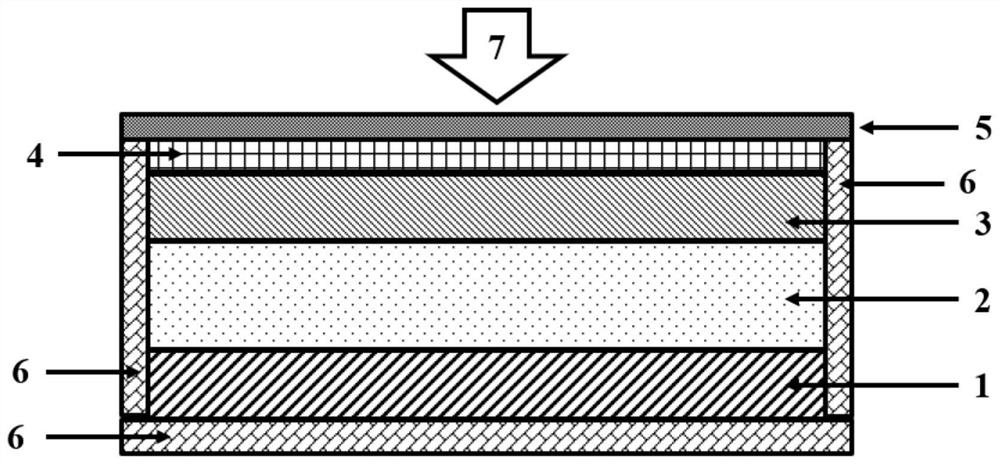

[0028] The present invention also provides a preparation method of a solid-state lithium-air battery, comprising the following steps: in an inert atmosphere or a dry atmosphere, a lithium negative electrode, a diaphragm, and an air positive electrode are arranged in the inner layer of a package casing to assemble the battery, wherein the lithium negative electrode, the diaphragm 1. The air positive electrode and the packaging shell form a housing cavity that can accommodate the electrolyte; the air positive electrode is connected to the diaphragm and is located on the side of the diaphragm away from the lithium negative electrode, the electrolyte is injected into the housing cavity, and the battery is packaged. After the battery is packaged, it does not touch the air; stand still After a period of time, after the electrolyte is polymerized, a solid-state lithium-air battery can be obtained; then the sealed window or air port on the positive side of the air is opened to connect t...

Embodiment 1

[0036] A solid-state lithium-air battery, comprising an air positive electrode, an electrolyte, a lithium negative electrode, and a packaging shell with an opening and closing function, the preparation method of which is as follows:

[0037] S1: Preparation of air positive electrode: Weigh carbon nanotube (CNT) and polytetrafluoroethylene (PTFE) binder at a mass percentage of 95:5, use deionized water as a dispersant, stir it evenly; then spray The method is to spray the slurry evenly on the aluminum mesh of the current collector, put it in an oven at 55°C for drying; then transfer it to a vacuum oven at 110°C for 12 hours to completely volatilize the dispersant;

[0038] S2: Preparation of the electrolyte: the polymerized monomer is 1,3-dioxolane (DOL), the volume accounts for 50% of the total volume of the electrolyte, and the organic solvent is tetraethylene glycol dimethyl ether (G4), which accounts for 50% of the total volume of the solution. 50% of the volume, the lithiu...

Embodiment 2

[0050] Other conditions are the same as in Example 1, except that S1) the preparation of the air positive electrode, the preparation method of Example 2 is: Ketjen black (KB) and polyvinylidene fluoride (PVDF) binder are mixed in a mass percentage of 92 : 8 weighed, with N-methylpyrrolidone (NMP) as a dispersant, it was stirred evenly to make a slurry; then the slurry was evenly sprayed onto the current collector carbon paper by the method of spraying, and put into a 55 ℃ oven for drying Dry; then transfer to a vacuum oven at 110°C for 12 hours to completely volatilize the dispersant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com