Five-block polymer, preparation method and application thereof, and five-block polymer electrolyte

A pentablock and polymer technology, applied in the manufacture of non-aqueous electrolytes, solid electrolytes, electrolyte batteries, etc., can solve the problem of low ion conductivity of lithium-ion batteries, high crystallinity of polyethylene oxide at room temperature, and low lithium-ion conductivity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention provides a method for preparing the above-described five-block polymer, comprising the following steps:

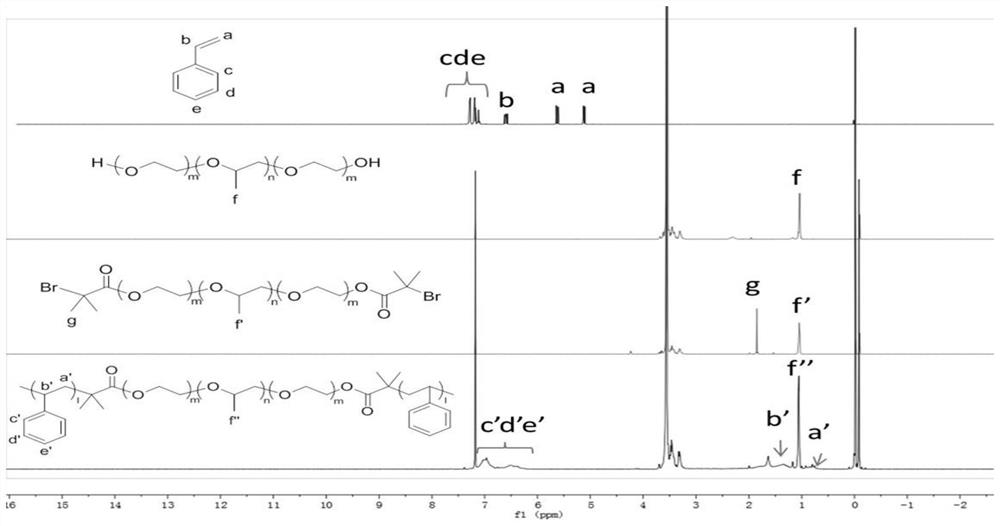

[0042] (1) The polyethylene oxide - polypropylene oxide - polyethylene oxide, bromoisobutyryl bromide, the first catalyst and the first organic solvent having the structure shown in formula b are mixed to obtain a macromolecular initiator having a structure shown in formula c;

[0043]

[0044] (2) The macromolecule initiator, styrene, second catalyst and second organic solvent having the structure shown in formula C are mixed to carry out atomic transfer radical polymerization reaction to obtain a five-block copolymer having the structure shown in formula a.

[0045] The present invention will have a structure shown in formula b polyethylene - polypropylene oxide - polyethylene oxide, bromoisobutyryl bromide, a first catalyst and a first organic solvent mixed, to give a macromolecular initiator having a structure shown in formula c. The present ...

Embodiment 1

[0076] Preparation of the five-block polymer electrolyte, the steps are as follows:

[0077] (1) 25.2g molecular weight 12600g / mol polyethylene oxide (PEO) - polypropylene oxide (PPO) - polyethylene oxide (PEO), 0.7330g4-dimethylaminopyridine, 0.66mL triethylamine dissolved in dichloromethane, the air in the device is excluded. The 1.24mL bromoisobutyryl bromide was dissolved in dichloromethane and slowly added to the above solution, and the reaction was stirred at room temperature for 24h to give PEO-PPO-PEO macromolecule initiator.

[0078] (2) 2.5512g PFO-PEO macromolecule initiator in step 1, 0.0574g cuprous bromide, 0.2mLN, N,N', N",N"-pentamethyldivinyltriamine, 2.3mL styrene dissolved in 1,4-dioxane, stirred at 100 °C for 24h to give a five-block polymer.

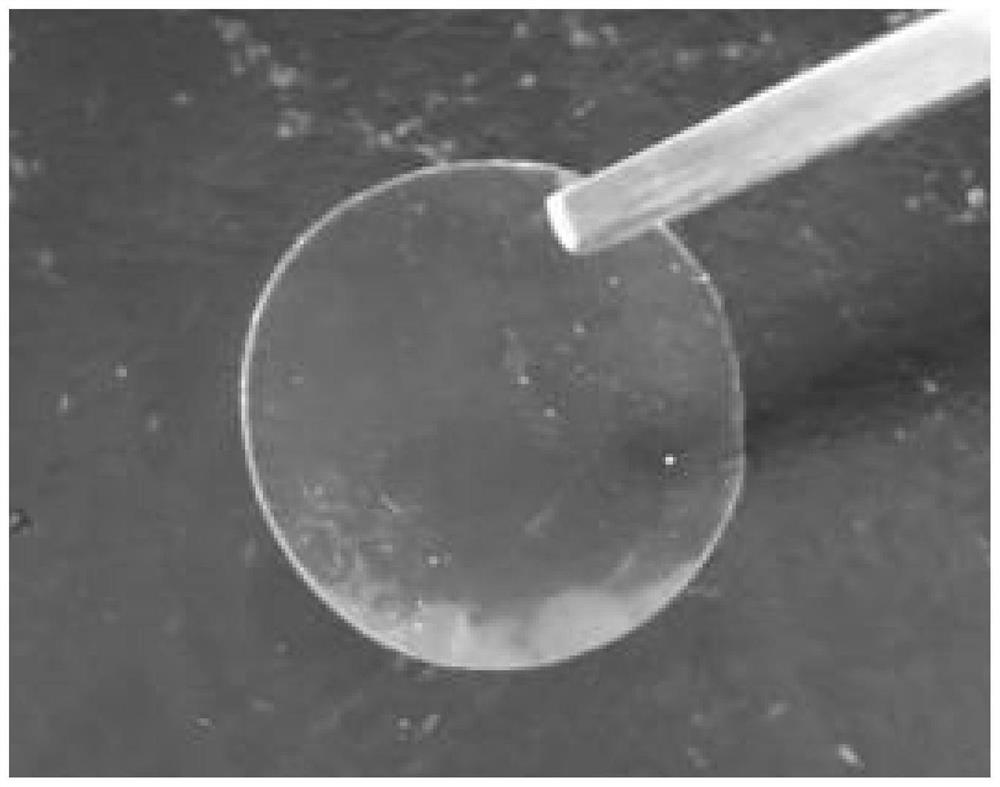

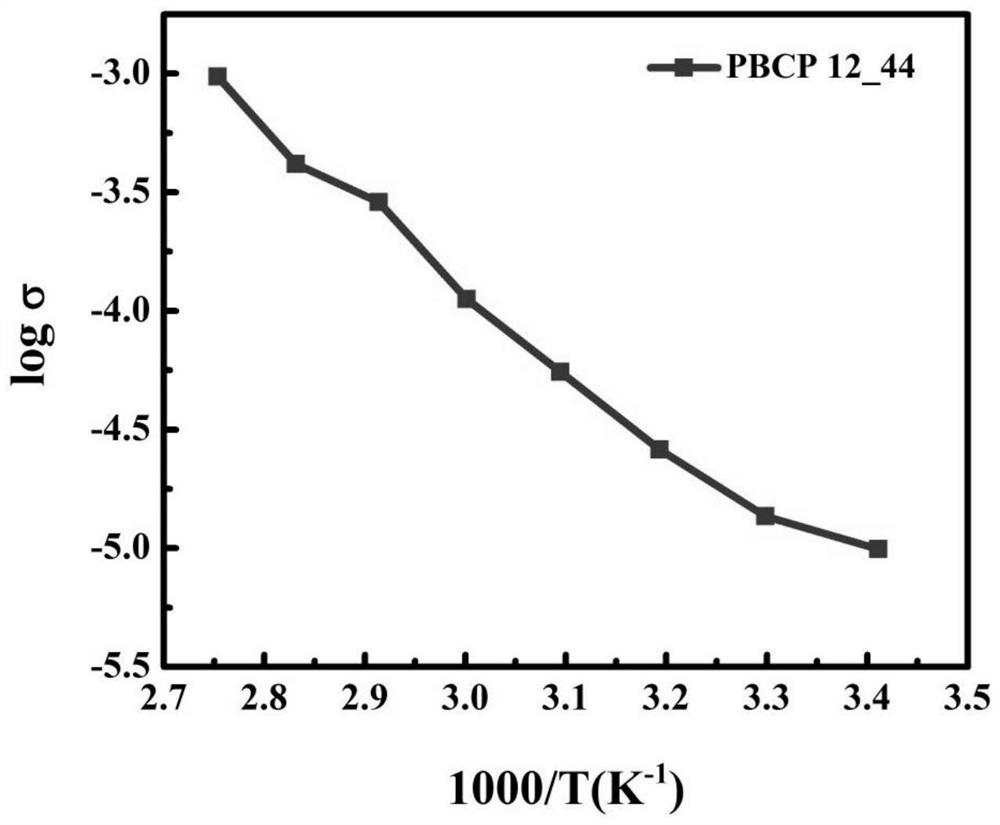

[0079] (3) 0.5g block polymer, 0.1430g LiTFSI dissolved in N, N- dimethylformamide, stirred at room temperature for 12h, the resulting slurry was scraped onto a 10×20cm rectangular polypropylene plate, dried at 60 °C i...

Embodiment 2

[0089]Preparation of the five-block polymer electrolyte, the steps are as follows:

[0090] (1) 25.2g molecular weight 12600g / mol polyethylene oxide (PEO) - polypropylene oxide (PPO) - polyethylene oxide (PEO), 0.7330g4-dimethylaminopyridine, 0.66mL triethylamine dissolved in dichloromethane, the air in the device is excluded. The 1.24mL bromoisobutyryl bromide was dissolved in dichloromethane and slowly added to the above solution, and the reaction was stirred at room temperature for 24h to give PEO-PPO-PEO macromolecule initiator.

[0091] (2) 2.5512g PFO-PEO macromolecule initiator in step 1, 0.0574g cuprous bromide, 0.2mLN, N,N', N",N"-pentamethyldivinyltriamine, 2.8mL styrene dissolved in 1,4-dioxane, stirred at 110 °C for 24h to give a five-block polymer.

[0092] (3) 0.5g five-block polymer, 0.1267g LiTFSI dissolved in N, N-dimethylformamide, stirred at room temperature for 12h, the resulting slurry was scraped onto a 10×20cm rectangular polypropylene plate, dried at 60 °...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com