Zinc-doped porous bioactive glass ceramic and preparation method thereof

A bioactive glass and ceramic technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of secondary fracture, elevation, change, etc., to promote the formation of new bone, improve the mechanical strength, and accelerate the reconstruction process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

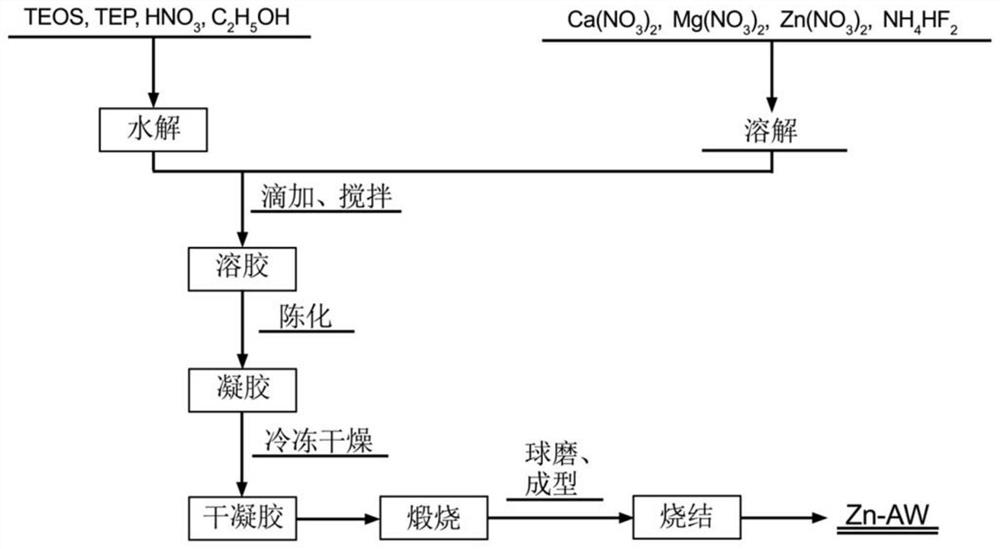

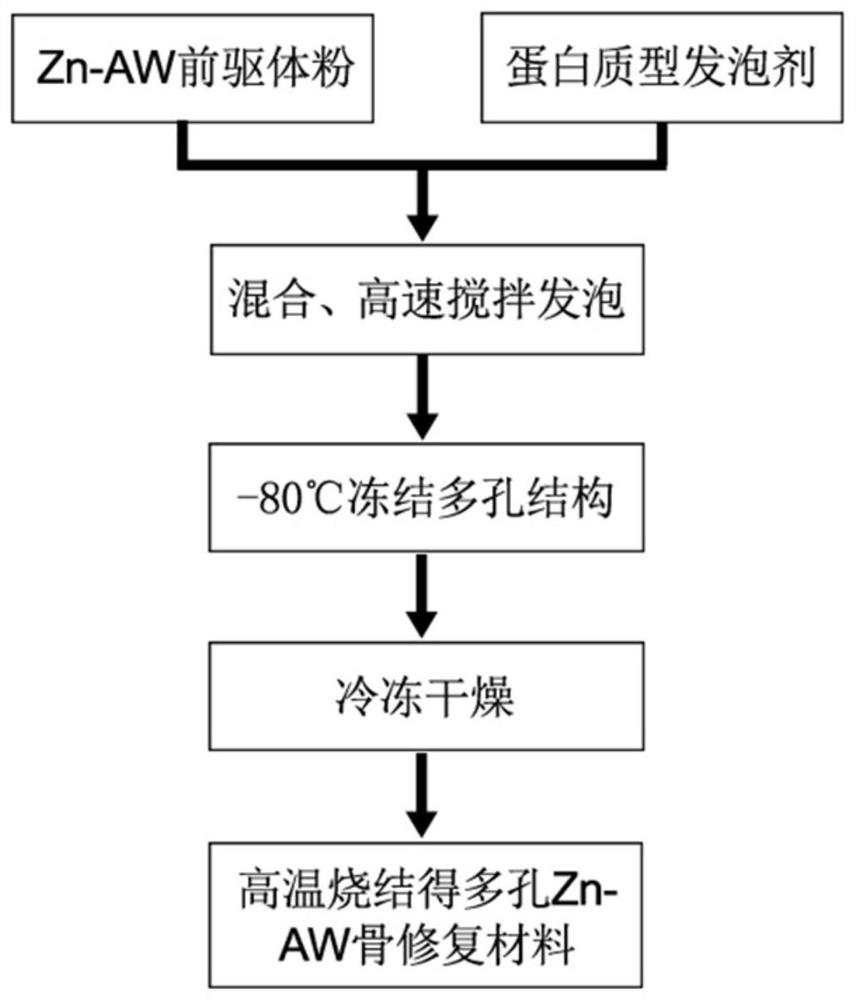

[0040] Step S1: Prepare Zn-AW precursor powder (such as figure 1 shown)

[0041] According to the molar ratio of 2.5:1, weigh tetraethyl orthosilicate (TEOS) and triethyl phosphate (TEP) and dissolve them in absolute ethanol solution (the molar ratio of TEOS to absolute ethanol is 6:7), and make it mix well;

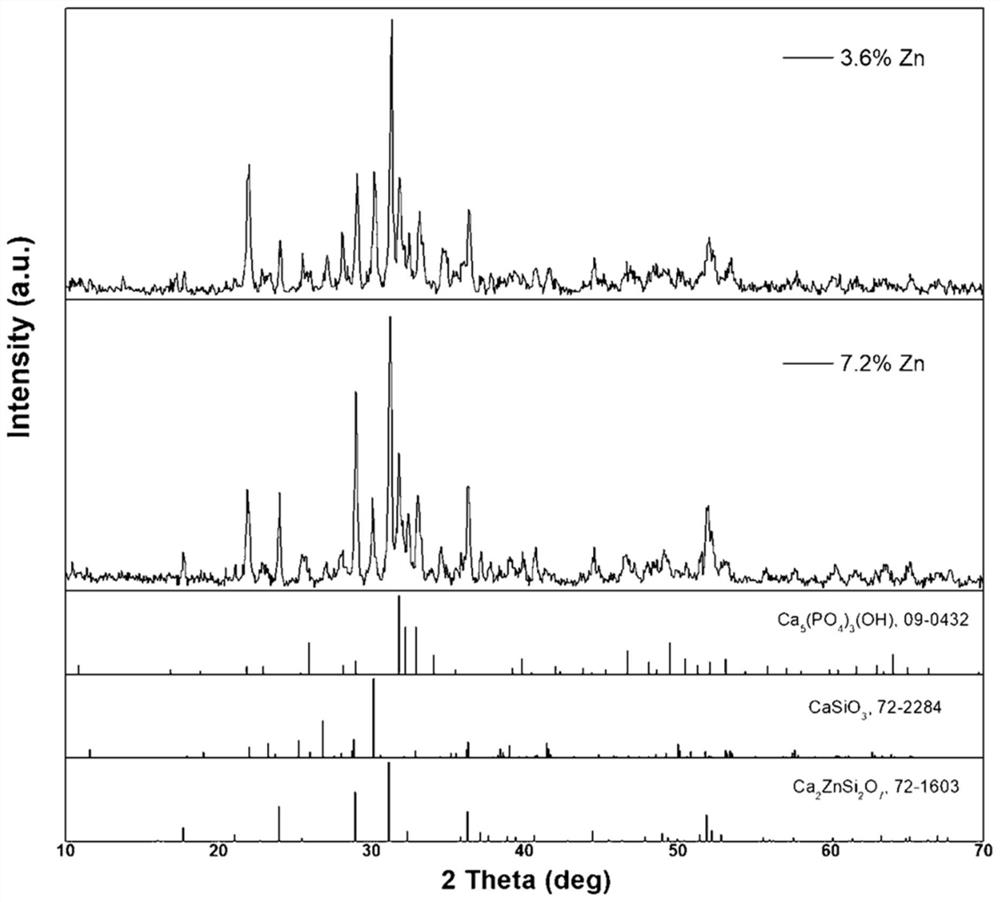

[0042] Weigh Mg(NO 3 ) 2 , Ca(NO 3 ) 2 , NH 4 HF 2 and Zn(NO 3 ) 2 , and dissolved in water (water and Ca(NO 3 ) 2 The molar ratio is 6:1) to obtain an inorganic solution, slowly add the inorganic solution dropwise to the above organic solution, and add HNO 3 Adjust the pH value of the mixed solution to 1.0, stir until a stable sol is formed, age at room temperature for 24 hours, put it into liquid nitrogen for rapid cooling, then transfer it to a vacuum freeze dryer, and fully freeze-dry it at -40°C to obtain zinc-containing Xerogel powder. The dry gel powder was calcined at 800°C and ball milled through a 200-mesh sieve to obtain the precursor powder.

[00...

Embodiment 2

[0047] Step S1: Preparation of Zn-AW precursor powder

[0048] According to the molar ratio of 2.5:1, weigh tetraethyl orthosilicate (TEOS) and triethyl phosphate (TEP) and dissolve them in ethanol solution (the molar ratio of TEOS to absolute ethanol is 6:7), and mix them well ;

[0049] Weigh Mg(NO 3 ) 2 , Ca(NO 3 ) 2 , NH 4 HF 2 and Zn(NO 3 ) 2 , and dissolved in water (water and Ca(NO 3 ) 2 The molar ratio is 6:1) to obtain an inorganic solution, slowly add the inorganic solution dropwise to the above organic solution, and add HNO 3 Adjust the pH value of the mixed solution to 1.3, stir until a stable sol is formed, age at room temperature for 24 hours, put it into liquid nitrogen for rapid cooling, then transfer it to a vacuum freeze dryer, and fully freeze-dry at -40°C to obtain zinc-containing dry powder. Gel powder. The dry gel powder was calcined at 800°C and ball milled through a 200-mesh sieve to obtain the precursor powder.

[0050] Step S2: Preparatio...

Embodiment 3

[0054] Step S1: Preparation of Zn-AW precursor powder

[0055] According to the molar ratio of 2.5:1, weigh tetraethyl orthosilicate (TEOS) and triethyl phosphate (TEP) and dissolve them in ethanol solution (the molar ratio of TEOS to absolute ethanol is 6:7), and mix them well ;

[0056] Weigh Mg(NO 3 ) 2 , Ca(NO 3 ) 2 , NH 4 HF 2 and Zn(NO 3 ) 2 , and dissolved in water (water and Ca(NO 3 ) 2 The molar ratio is 6:1) to obtain an inorganic solution, slowly add the inorganic solution dropwise to the above organic solution, and add HNO 3 Adjust the pH value of the mixed solution to 1.3, stir until a stable sol is formed, age at room temperature for 24 hours, put it into liquid nitrogen for rapid cooling, then transfer it to a vacuum freeze dryer, and fully freeze-dry at -40°C to obtain zinc-containing dry powder. Gel powder. The dry gel powder was calcined at 800°C and ball milled through a 200-mesh sieve to obtain the precursor powder.

[0057] Step S2: Preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com