Environment-friendly bamboo mildew-proof treatment method

A treatment method, an environmentally friendly technology, applied in wood treatment, wood treatment details, reed/straw treatment, etc., can solve the problems of easy mildew, bamboo easy to mildew, and can not be used for anti-mildew treatment, etc., to improve the size Stability, improved anti-mildew performance, significant economic value and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

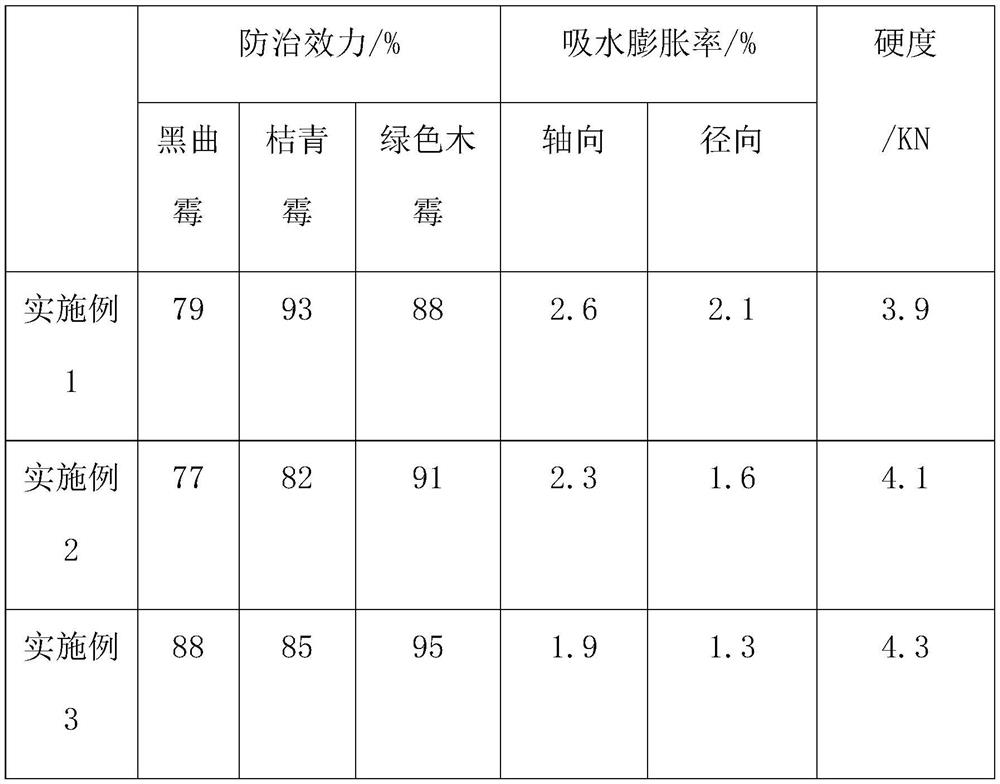

Embodiment 1

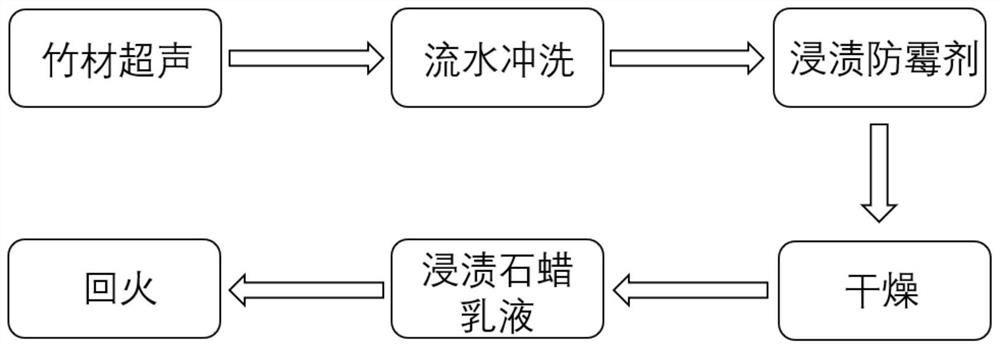

[0020] Embodiment 1: the processing method of the environment-friendly type bamboo material mildewproof of the present embodiment, its steps are as follows:

[0021] Step 1) Soak the bamboo that has been degreened and deyellowed in water, and perform ultrasonic treatment, the ultrasonic frequency is 50KHz, the ultrasonic power is 400W, the ultrasonic time is 1h, and the ultrasonic temperature is 20°C;

[0022] Step 2) Rinse the ultrasonically treated bamboo with running water for 1 hour;

[0023] Step 3) the bamboo after washing is placed in compound anti-mold agent, compound anti-mold agent is made up of sodium acetate and butylparaben, and its mass ratio is 1:1, adds a certain amount of water, at 20 Stir at ℃ for 10 minutes, prepare a solution with a concentration of 0.6%, and soak for 1 hour at normal temperature and pressure;

[0024] Step 4) drying the bamboo treated with the antifungal agent at 30°C, and controlling the moisture content at 8%;

[0025] Step 5) Put the ...

Embodiment 2

[0028] Embodiment 2: the processing method of the environment-friendly type bamboo anti-mold of the present embodiment, its steps are as follows:

[0029] Step 1) Soak the degreened and yellowed bamboo in water, and perform ultrasonic treatment, the ultrasonic frequency is 80KHz, the ultrasonic power is 600W, the ultrasonic time is 1.5h, and the ultrasonic temperature is 40°C;

[0030] Step 2) Rinse the ultrasonically treated bamboo with running water for 1.5 hours;

[0031] Step 3) the bamboo after washing is placed in compound anti-mold agent, compound anti-mold agent is made up of sodium diacetate and butylparaben, and its mass ratio is 2:1, adds a certain amount of water, in Stir at 35°C for 20 minutes, prepare a solution with a concentration of 1.0%, and soak for 1.5 hours at normal temperature and pressure;

[0032] Step 4) drying the bamboo treated with the antifungal agent at 40°C, the moisture content is controlled at 10%;

[0033] Step 5) Put the dried bamboo in th...

Embodiment 3

[0036] Embodiment 3: the processing method of the environment-friendly type bamboo material mildewproof of the present embodiment, its steps are as follows:

[0037] Step 1) Soak the bamboo that has been degreened and deyellowed in water, and perform ultrasonic treatment, the ultrasonic frequency is 100KHz, the ultrasonic power is 800W, the ultrasonic time is 2h, and the ultrasonic temperature is 80°C;

[0038] Step 2) Rinse the ultrasonically treated bamboo with running water for 2 hours;

[0039] Step 3) the bamboo after washing is placed in compound anti-mold agent, compound anti-mold agent is made up of sodium diacetate and propylparaben, and its mass ratio is 3:1, adds a certain amount of water, in Stir at 50°C for 30 minutes, prepare a solution with a concentration of 1.4%, soak for 2 hours at normal temperature and pressure;

[0040] Step 4) dry the bamboo after the antifungal agent treatment at 50°C, and control the moisture content at 12%;

[0041] Step 5) Place the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com