Method for introducing fluorine ions into ZnMoO4 through hydrothermal method

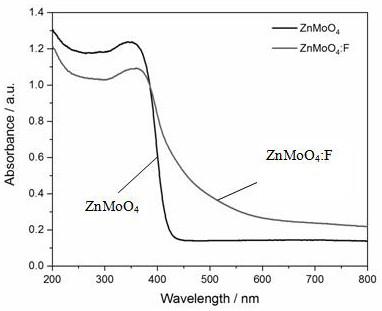

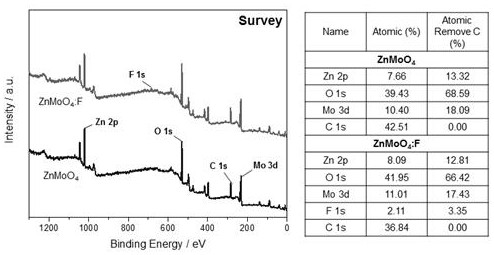

A technology of fluoride ion and hydrothermal method, which is applied in chemical instruments and methods, inorganic chemistry, molybdenum compounds, etc., can solve the problems of difficulty in confirming the existence of fluoride ion, danger, single synthesis method, etc., and achieve the improvement of visible light activity and high efficiency. Synthetic method, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

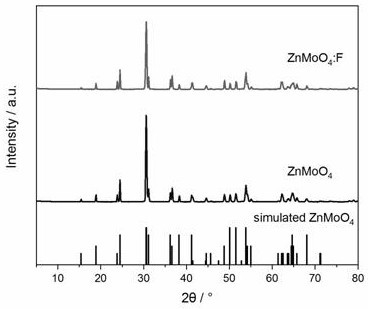

[0026] A hydrothermal method on ZnMoO 4 The method for importing fluoride ions in the present invention comprises the following steps:

[0027] a. Weigh 432.2 mg of molybdenum trioxide and dissolve it in 70 ml of deionized water, then weigh 527.5 mg of zinc fluoride tetrahydrate and add it to the molybdenum trioxide aqueous solution;

[0028] b. Transfer the mixed solution obtained in step a to a 100ml reaction kettle, and conduct a hydrothermal reaction at a temperature of 150° C. for 20 hours to obtain a yellow product;

[0029] c. Repeated centrifugal washing of the yellow product obtained in step b with deionized water and ethanol, vacuum drying at 50°C for 10 hours, and grinding into powder to obtain ZnMoO 4 :F.

Embodiment 2

[0031] A hydrothermal method on ZnMoO 4 The method for importing fluoride ions in the present invention comprises the following steps:

[0032] a. Weigh 432.8 mg of molybdenum trioxide and dissolve it in 70 ml of deionized water, then weigh 527.2 mg of zinc fluoride tetrahydrate and add it to the molybdenum trioxide aqueous solution;

[0033] b. Transfer the mixed solution obtained in step a to a 100ml reaction kettle, and conduct a hydrothermal reaction at a temperature of 180° C. for 12 hours to obtain a yellow product;

[0034] c. Repeated centrifugal washing of the yellow product obtained in step b with deionized water and ethanol, vacuum drying at 80°C for 6 hours, and grinding into powder to obtain ZnMoO 4 :F.

Embodiment 3

[0036] A hydrothermal method on ZnMoO 4 The method for importing fluoride ions in the present invention comprises the following steps:

[0037] a. Weigh 432.0 mg of molybdenum trioxide and dissolve it in 70 ml of deionized water, then weigh 527.0 mg of zinc fluoride tetrahydrate and add it to the molybdenum trioxide aqueous solution;

[0038] b. Transfer the mixed solution obtained in step a to a 100ml reaction kettle, and conduct a hydrothermal reaction at a temperature of 200° C. for 24 hours to obtain a yellow product;

[0039] c. Repeated centrifugal washing of the yellow product obtained in step b with deionized water and ethanol, vacuum drying at 60°C for 12 hours, and grinding into powder to obtain ZnMoO 4 :F.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com