System and method for continuously producing diethyl methylphosphite

A technology of diethyl methylphosphonite and methylphosphine dichloride, which is applied in the field of continuous production of diethyl methylphosphonite, can solve the problem of low processing capacity of a single device, complex microreactor structure, micro Reactor channel is small, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

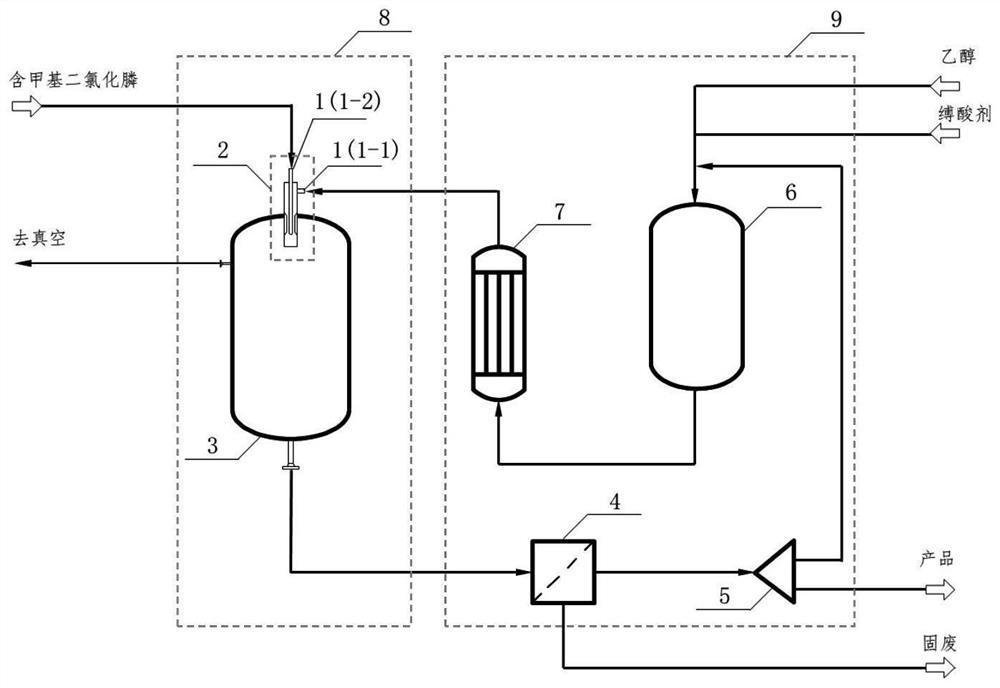

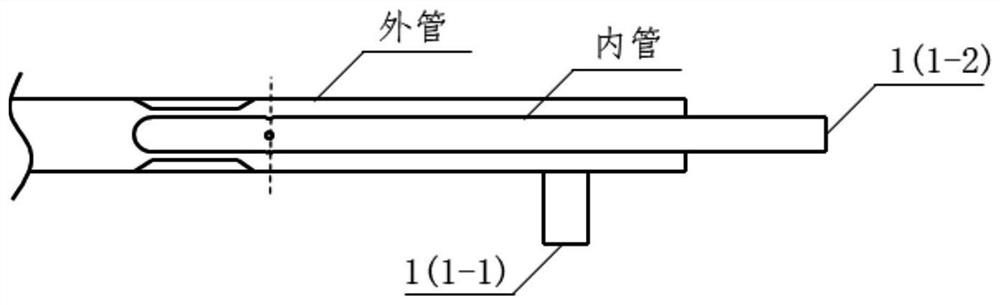

[0074] figure 1 The structural representation of the system for the continuous production of diethyl methylphosphonite provided in Example 1; wherein, comprising a fast mixing reactor (8) and a material circulation subsystem (9); the fast mixing reactor (8 ) is provided with a rapid mixing member (2) at the inlet, and the rapid mixing member (2) is a Venturi nozzle, see figure 2 As shown; the material circulation subsystem (9) includes a filter (4), a material distribution unit (5), an acid-binding agent premixer (6) and a heat exchanger (7).

[0075] Such as figure 1 Shown, rapid mixing member (2) comprises first liquid inlet 1 (1-1) and second liquid inlet 1 (1-2); Rapid mixing reactor (8) outlet links to each other with filter (4) inlet, uses Remove the solid components generated in the rapid mixing reactor (8); the liquid outlet of the filter (4) is connected to the material distribution unit (5), a part of the liquid is extracted as a product, and a part of the liquid ...

Embodiment 2

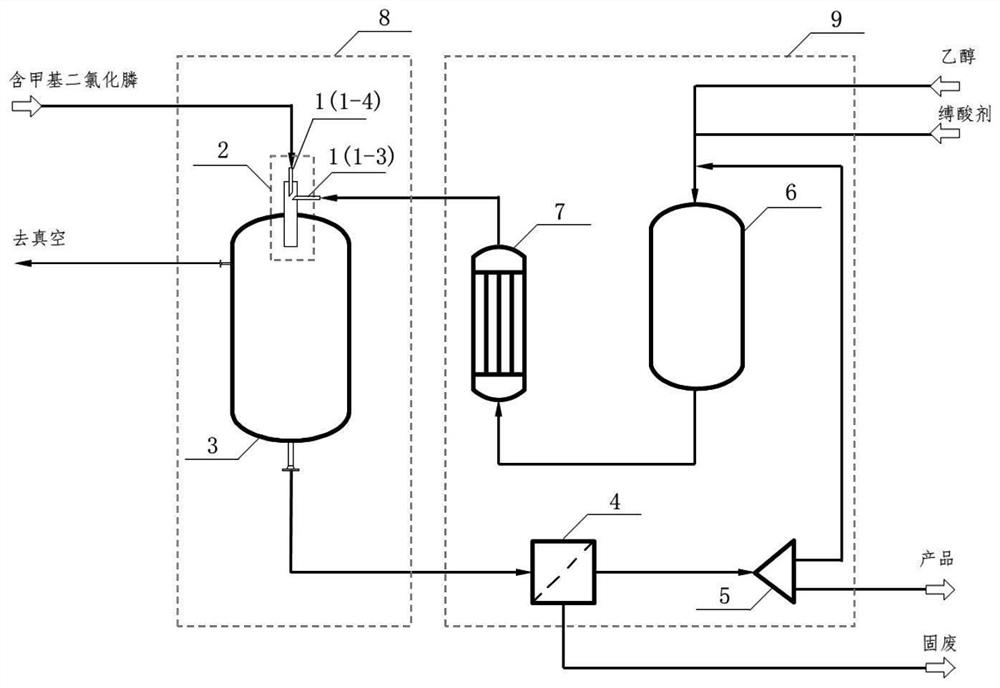

[0078] image 3 The structural representation of the system for the continuous production of diethyl methylphosphonite provided in Example 2; wherein, comprising a fast mixing reactor (8) and a material circulation subsystem (9); the fast mixing reactor (8 ) is provided with a rapid mixing member (2) at the inlet, and the rapid mixing member (2) is a jet nozzle, see figure 2 As shown; the material circulation subsystem (9) includes a filter (4), a material distribution unit (5), an acid-binding agent premixer (6) and a heat exchanger (7).

[0079] Such as image 3 Shown, rapid mixing member (2) comprises first liquid inlet 1 (1-3) and second liquid inlet 1 (1-4); Rapid mixing reactor (8) outlet links to each other with filter (4) inlet, uses Remove the solid components generated in the rapid mixing reactor (8); the liquid outlet of the filter (4) is connected to the material distribution unit (5), a part of the liquid is extracted as a product, and a part of the liquid ente...

Embodiment 3

[0082] Figure 5 The structural representation of the system for the continuous production of diethyl methylphosphonite that embodiment 3 provides; Wherein, comprise fast mixing reactor (8) and material circulation subsystem (9); Described fast mixing reactor (8 ) is provided with a rapid mixing member (2) at the inlet, and the rapid mixing member (2) is a counterflow nozzle, see Image 6 As shown; the material circulation subsystem (9) includes a filter (4), a material distribution unit (5), an acid-binding agent premixer (6) and a heat exchanger (7).

[0083] Such as Figure 5 Shown, rapid mixing member (2) comprises first liquid inlet 1 (1-5) and second liquid inlet 1 (1-6); Rapid mixing reactor (8) outlet links to each other with filter (4) inlet, uses Remove the solid components generated in the rapid mixing reactor (8); the liquid outlet of the filter (4) is connected to the material distribution unit (5), a part of the liquid is extracted as a product, and a part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com