MoO3/P6ICA composite electrode material and preparation method thereof and supercapacitor

A supercapacitor and composite electrode technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of electrochromism, poor stability of conductive polymers, poor capacitance performance and electrochemical stability, etc. Achieve strong adhesion, improve stability, and improve electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

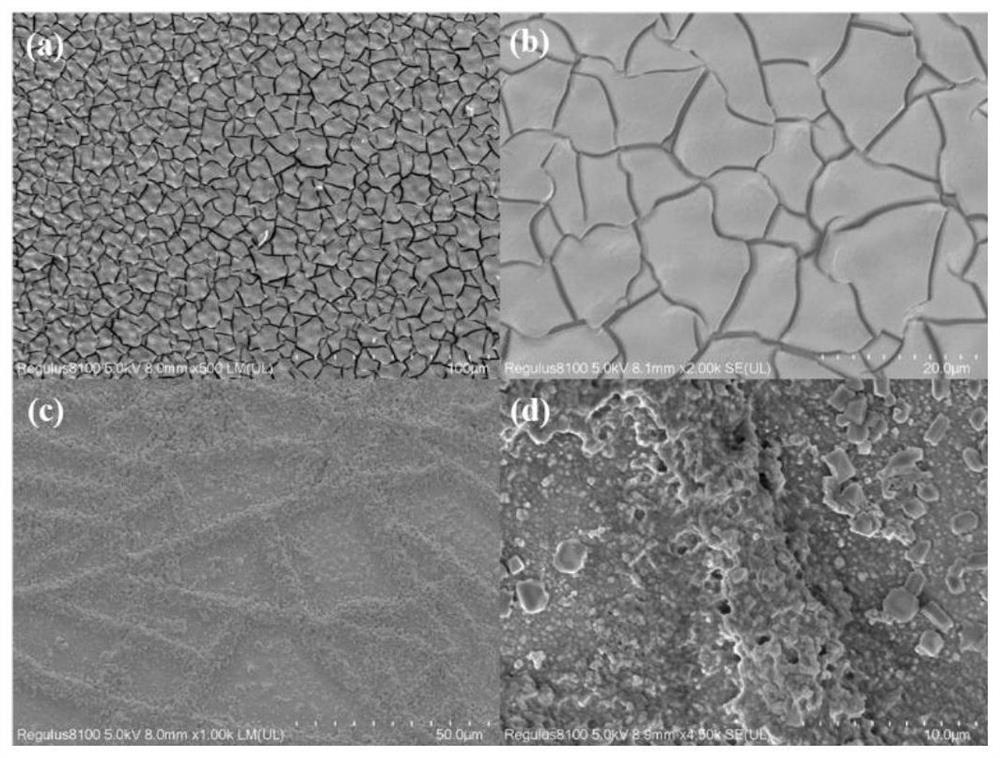

[0030] Example 1MoO 3 Preparation of / P6ICA composite electrode material

[0031] Preparation of MoO by Electrodeposition 3 Base:

[0032] Cut the FTO conductive glass into a size of 0.7cm×5cm with a glass knife, clean it with ethanol, acetone, and ultrapure water for 10 minutes, and then use a multimeter to measure the FTO conductive surface; weigh 0.088g of ammonium molybdate tetrahydrate [(NH 4 )Mo 7 o 24 4H 2 O] dissolved in 5ml of water, ultrasonic 5min until completely dissolved, as the electrochemical polymerization solution 1.

[0033] A one-chamber three-electrode system was used for deposition. First, sand the Ag with a diameter of 0.5mm until it is smooth, burn the Pt wire with a diameter of 0.3mm to red with an open flame, then connect the Ag wire to the working electrode and the Pt wire to the reference electrode; 6mol L -1 In the hydrochloric acid solution, the electrolysis process occurs under the condition of a constant potential of 1.5V and 100s. When ...

Embodiment 2

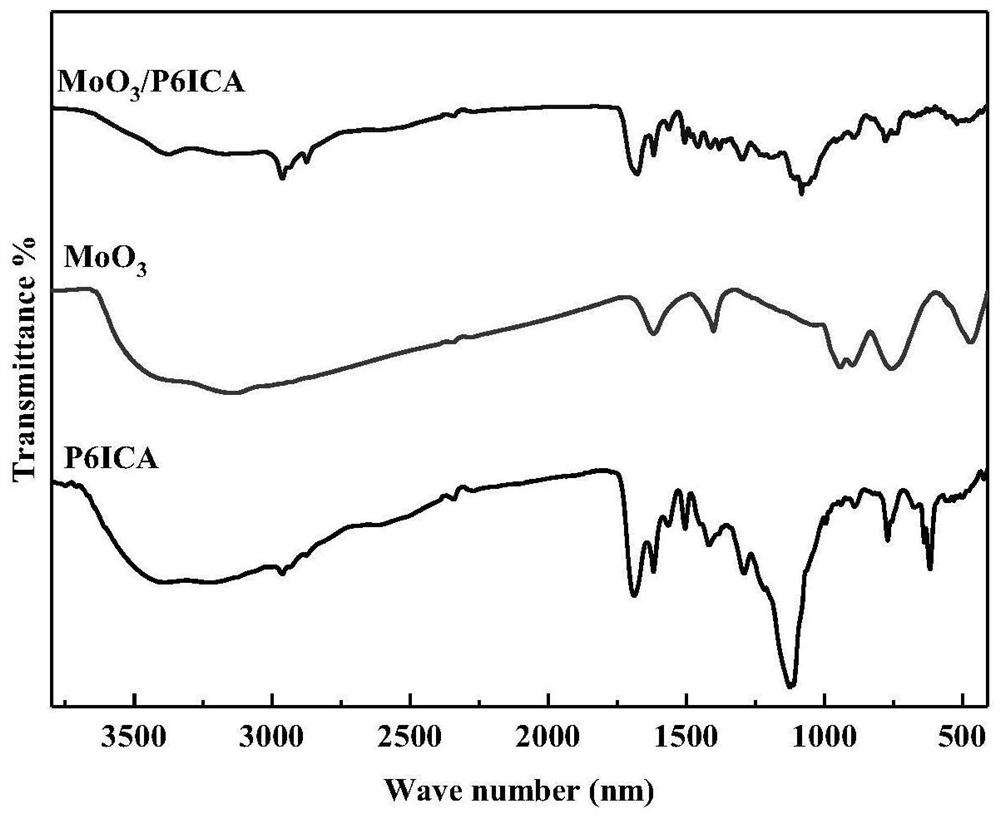

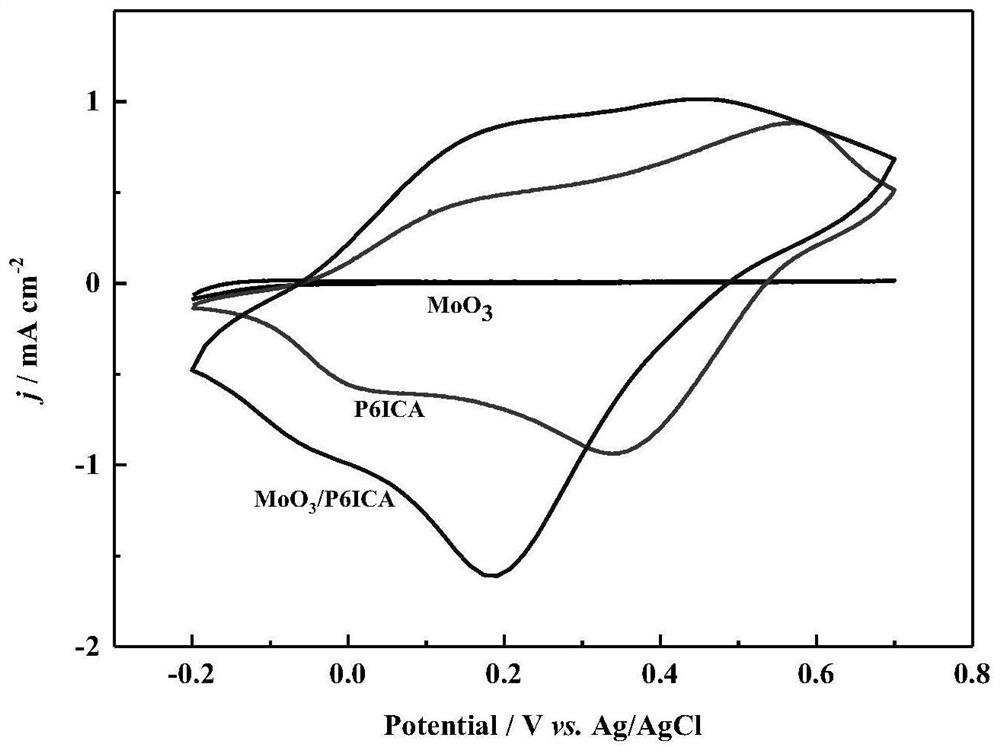

[0036] Example 2MoO 3 Electrochemical performance characterization of / P6ICA composite electrode material

[0037] Now to the MoO that embodiment 1 prepares 3 / P6ICA composite electrode material for the following various electrochemical characterizations, first, select the electrolyte required for the characterization of the composite material, MoO 3 / P6ICA composite electrode material composite materials containing electrolyte 0.1mol L -1 Tetrabutylammonium boron tetrafluoride (TBATFB) in acetonitrile organic solution, in 0.1mol L -1 Alkaline solution of NaOH, in 0.1mol L -1 h 2 SO 4 Acidic solution, in 0.1mol L -1 Na 2 SO 4 Electrochemical cyclic voltammetry, impedance test and other charge and discharge tests in neutral solution all fall off and dissolve; the final proof is 0.095mol L -1 Na 2 SO 4 +0.005mol L - 1 h 2 SO 4 The test in the solution can always adhere to the electrode without falling off, which is conducive to the stability of electrochemical per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com