Liquid metal flexible electron and preparation method and application thereof

A liquid metal, flexible technology, applied in applications, other household appliances, printed circuit manufacturing, etc., can solve problems such as high cost, unsuitable for large-scale application promotion, and cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

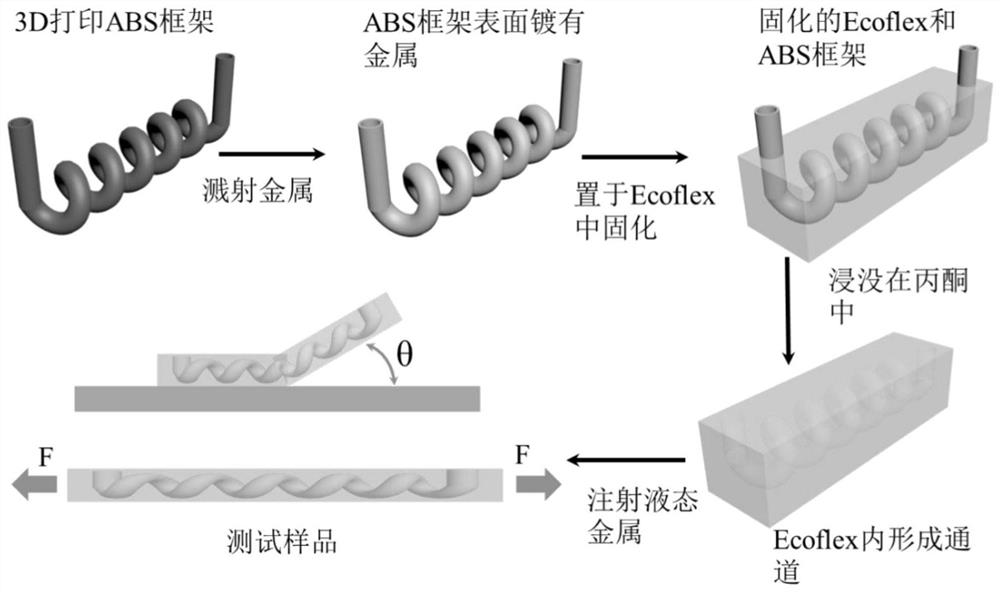

[0041] The invention provides a method for preparing liquid metal flexible electronics, comprising the following steps;

[0042] According to the circuit pattern, the ABS plastic model is obtained by 3D printing;

[0043] Ion sputtering is carried out on the surface of the ABS plastic model to form a gold film to obtain a gold-plated ABS circuit;

[0044] Putting Ecoflex silica gel into the mold, then placing the gold-plated ABS circuit in the air in the mold, so that the gold-plated ABS circuit does not contact the mold, and then curing to obtain a cured model;

[0045] The cured model was soaked in acetone to dissolve the ABS plastic model, and a microchannel with gold plating on the inner wall was obtained in the Ecoflex substrate;

[0046] Injecting gallium indium eutectic into the microchannel with gold plating on the inner wall, then inserting copper wires into the liquid metal at both ends of the microchannel with gold plating on the inner wall, and then attaching gold p...

Embodiment 1

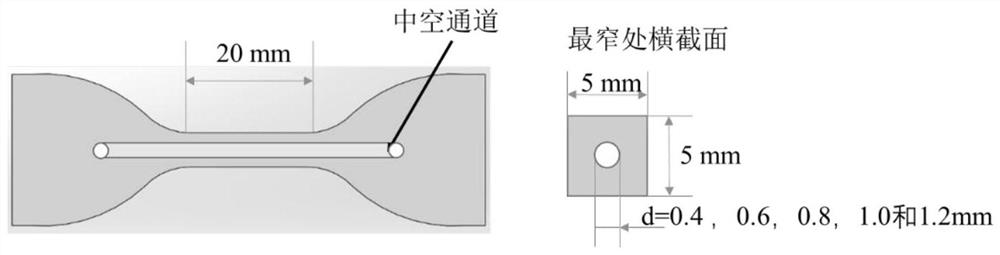

[0065] Use relevant software to draw circuit patterns in the computer, and print out the ABS plastic model with a 3D printer; place the printed ABS plastic model in an ion sputtering device for 60 seconds, and coat a layer of gold film on its surface; Put the silica gel into the mold, then place the gold-plated ABS circuit in the air, let it stand at room temperature for 2 hours to cure, and get the cured model; soak the cured model (including the cured Ecoflex and ABS model) together in the acetone solution for 12 hours , acetone dissolves the ABS model, takes out the Ecoflex in which the ABS is completely dissolved from the acetone solution, and after rinsing, a microchannel with gold plating on the inner wall is obtained in the Ecoflex substrate; the gallium indium eutectic (EGaIn, Ga: 74.5%, In: 25.5%, wt%) is injected from one end of the channel, and then a copper wire with a length of 60mm is inserted into the liquid metal at both ends of the channel, and then Ecoflex sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com