Creep compound feed for suckling pigs and preparation method thereof

A trough compounding and feed technology, applied in the field of feed preparation, can solve the problems of unable to meet the nutritional needs of suckling pigs, non-standard production process, and extensive selection of raw materials, so as to improve the average body weight and survival rate, prevent the growth of microorganisms, and ensure the hygiene level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

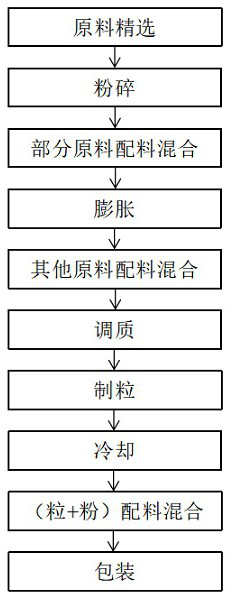

Method used

Image

Examples

Embodiment 1

[0036] Prepare materials in parts by weight: 580 parts of corn, 21 parts of wheat bran, 22 parts of fish meal, 69 parts of rice protein powder, 155 parts of soybean meal, 28 parts of whey powder, 31 parts of edible sugar, 32 parts of soybean oil, and 0.20 parts of antioxidant , 22 parts of additives and 12 parts of premix.

[0037] The additives include probiotics, emulsifiers and acidifiers, and the ratio of the parts by weight of the three is 1:1:1.

[0038] The probiotics are active lactic acid bacteria, the emulsifier is soybean lecithin extract, and the acidifier is calcium DL-hydroxymethionine.

[0039] The premix includes a vitamin premix and a trace element premix, and the ratio of the two parts by weight is 1:1.

[0040] The vitamin premix is vitamin A.

[0041] The trace element premix is iron.

[0042] Put corn, wheat bran, fish meal, rice protein powder, soybean meal, whey powder, and edible sugar into a grinder for crushing, and then combine them with soybe...

Embodiment 2

[0045] Prepare materials in parts by weight: 620 parts of corn, 25 parts of wheat bran, 16 parts of fish meal, 62 parts of rice protein powder, 70 parts of soybean meal, 22 parts of whey powder, 38 parts of edible sugar, 40 parts of soybean oil, and 0.08 parts of antioxidant , 28 parts of additives and 8 parts of premix.

[0046] The additives include probiotics, emulsifiers and acidifiers, and the ratio of the parts by weight of the three is 1:1:1.

[0047] The probiotics are active lactic acid bacteria, the emulsifier is soybean lecithin extract, and the acidifier is calcium DL-hydroxymethionine.

[0048] The premix includes a vitamin premix and a trace element premix, and the ratio of the two parts by weight is 1:1.

[0049] Vitamin premix is vitamin A, D 3 , E, K 3 , the four are prepared according to 1:1:1:1.

[0050] The trace element premix is copper, iron, and manganese, and the three are prepared at a ratio of 1:1:1:1.

[0051] Put corn, wheat bran, fish meal, ...

Embodiment 3

[0054] In parts by weight, 600 parts of corn, 22 parts of wheat bran, 18 parts of fish meal, 65 parts of rice protein powder, 165 parts of soybean meal, 25 parts of whey powder, 35 parts of edible sugar, 35 parts of soybean oil, 0.1 part of antioxidant, additives 24.9 parts and 10 parts of premix, the additives include probiotics, emulsifiers and acidulants, and the ratio of the parts by weight of the three is 1:1:1.

[0055] The probiotics are active lactic acid bacteria, the emulsifier is soybean lecithin extract, and the acidifier is calcium DL-hydroxymethionine.

[0056] The premix includes a vitamin premix and a trace element premix, and the ratio of the two parts by weight is 1:1.

[0057] Vitamin premixes including vitamins A, D 3 , E, K 3 , B 1 , B 2 , B 6 , folic acid, pantothenic acid, niacin, each component is evenly distributed.

[0058] The trace element premix includes copper, iron, manganese, zinc, iodine, selenium, and each component is evenly dosed.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com