Caprolactam production wastewater treatment method

A technology for producing wastewater and caprolactam, which is applied in biological water/sewage treatment, heating water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of waste of resources, difficult operation, complicated process, etc., and reduce energy consumption , production cost reduction, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

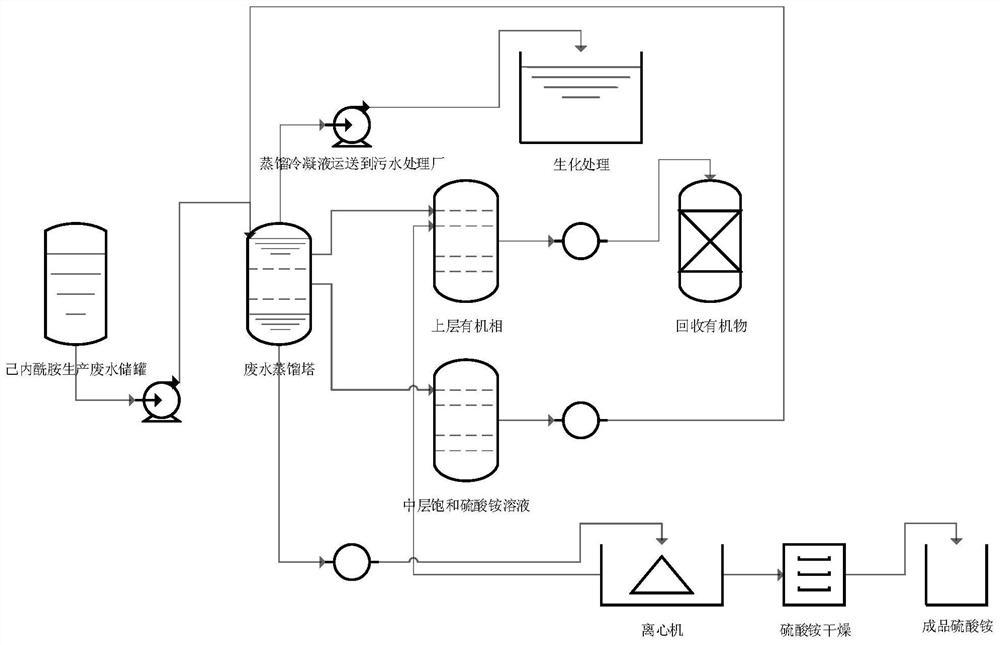

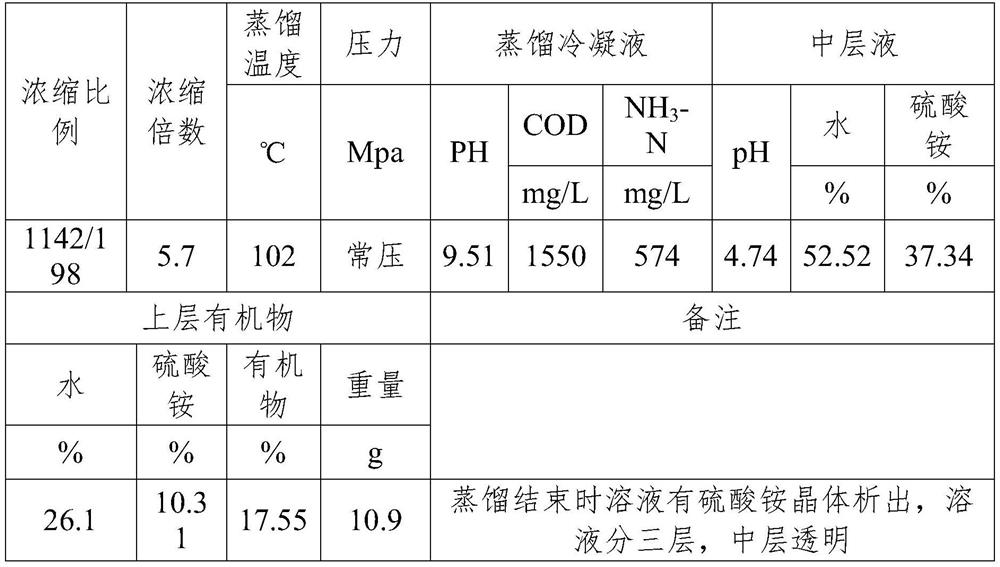

[0043] The processing method of caprolactam production waste water, it comprises the following steps carried out in sequence:

[0044] S1 Distillation treatment of production wastewater: The caprolactam production wastewater is subjected to continuous feed distillation at 100°C under normal pressure. During the distillation process, the distillation condensate and distillation raffinate are continuously obtained. The discharge speed is the same, distill until the distillation raffinate has crystals, and the distillation raffinate is concentrated 4 times compared to the original caprolactam production wastewater; the content of COD in the distillation process of caprolactam production wastewater is 1500mg / L, ammonia nitrogen is 200~600mg / L L, the pH of the distillate is 8.5-9.5.

[0045] S2 Distillation raffinate recovery: The obtained distillation raffinate is left to stand for stratification, divided into upper layer material, middle layer liquid and lower layer crystal, and ...

Embodiment 2

[0049] The difference is that the temperature of the atmospheric pressure feed distillation treatment is 90° C., the feed speed during the distillation process is greater than the distillation discharge speed, and the distillation raffinate is concentrated 5 times relative to the original caprolactam production wastewater. Others are the same as in Example 1.

[0050] In the upper liquid prepared in this embodiment, the content of organic matter was 16.62%.

Embodiment 3

[0052] The difference is that the temperature of the atmospheric pressure feed distillation treatment is 120° C., and the distillation raffinate is concentrated 6 times relative to the original caprolactam production wastewater, and the others are the same as in Example 1.

[0053] In the upper layer liquid prepared in this embodiment, the content of organic matter was 16.32%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com