Composition for forming organic film, substrate for manufacturing semiconductor device, method for forming organic film, pattern forming method, and polymer

An organic film and composition technology, which is used in semiconductor/solid-state device manufacturing, optomechanical equipment, components for optomechanical processing, etc., and can solve the problems of film thickness variation, unexplained flattening properties of landfill properties, etc. , to achieve high-level filling/planarization characteristics, high heat-resistant filling/planarization characteristics, and good yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0244] In the preparation of the aforementioned polymer, two or more kinds of Y-X, or halides different from Y-X, or toluenesulfonate and methanesulfonate can be combined according to the required properties. Compounds containing a side chain structure that contributes to improvement in planarization characteristics and a rigid aromatic ring structure that contributes to etching resistance and heat resistance can be combined in any ratio. A composition for forming an organic film using a polymer obtained from these compounds can achieve both embedding / planarization properties and etching resistance at a high level.

[0245]As mentioned above, if it is the polymer of this invention, it will provide the composition for organic film formation which has the heat resistance of 400 degreeC or more, and a high degree of embedding / planarization characteristic simultaneously.

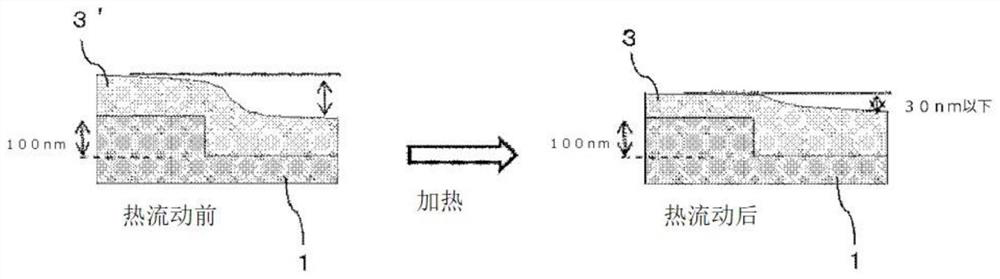

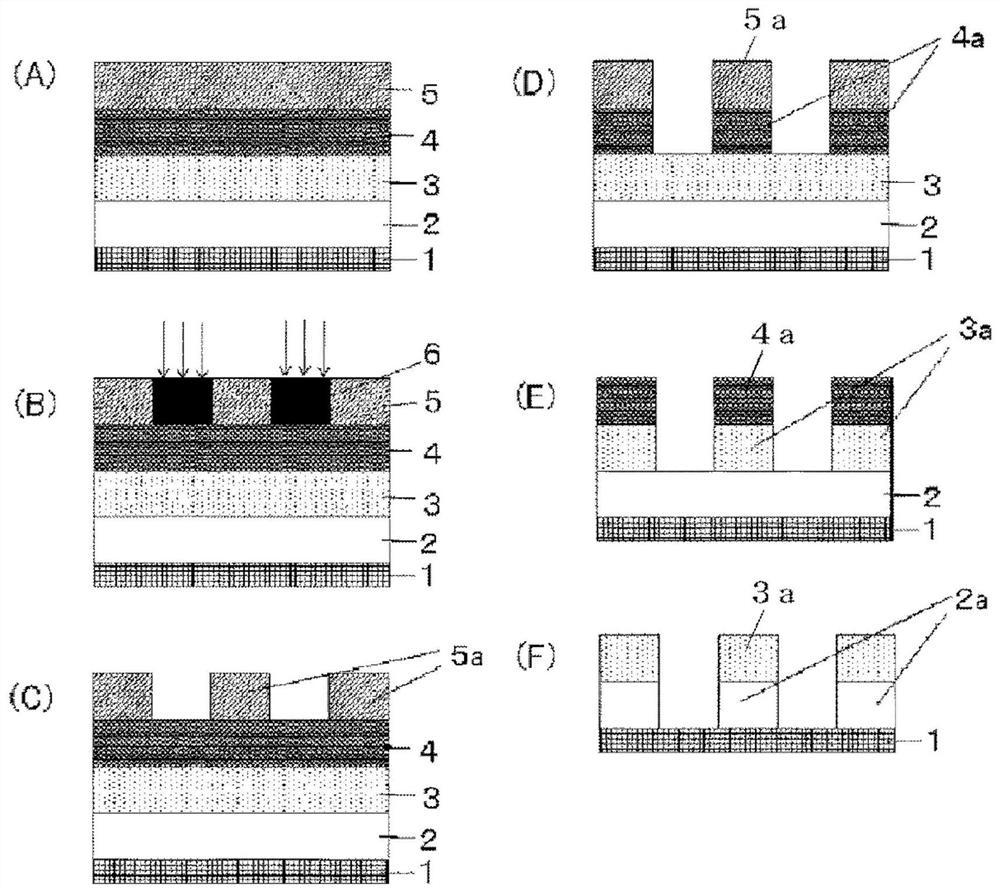

[0246] In addition, in the present invention, the flattening property refers to the performance of flattening...

Embodiment

[0319] Hereinafter, the present invention will be described more specifically by illustrating synthesis examples, comparative synthesis examples, examples, and comparative examples, but the present invention is not limited thereto. In addition, in terms of molecular weight and degree of dispersion, polystyrene-equivalent weight average molecular weight (Mw) and number average molecular weight ( Mn), and obtain the degree of dispersion (Mw / Mn, also known as molecular weight distribution).

Synthetic example

[0320] [Synthesis Example Synthesis of Polymer]

[0321] Syntheses of polymers (A1) to (A18) used compound group B: (B1) to (B16) and compound group C: (C1) to (C4) shown below.

[0322] Compound group B:

[0323] [chemical 50]

[0324]

[0325] Compound group C:

[0326] [Chemical 51]

[0327]

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com