Phase-change energy-storage composite film with sandwich structure and preparation method thereof

A sandwich structure, phase change energy storage technology, applied in the direction of chemical instruments and methods, heat exchange materials, sustainable manufacturing/processing, etc., can solve the problems of limiting the application of phase change materials, poor recyclability, easy phase separation, etc. Problems, to achieve good thermal stability and recyclability, low cost, good heat setting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

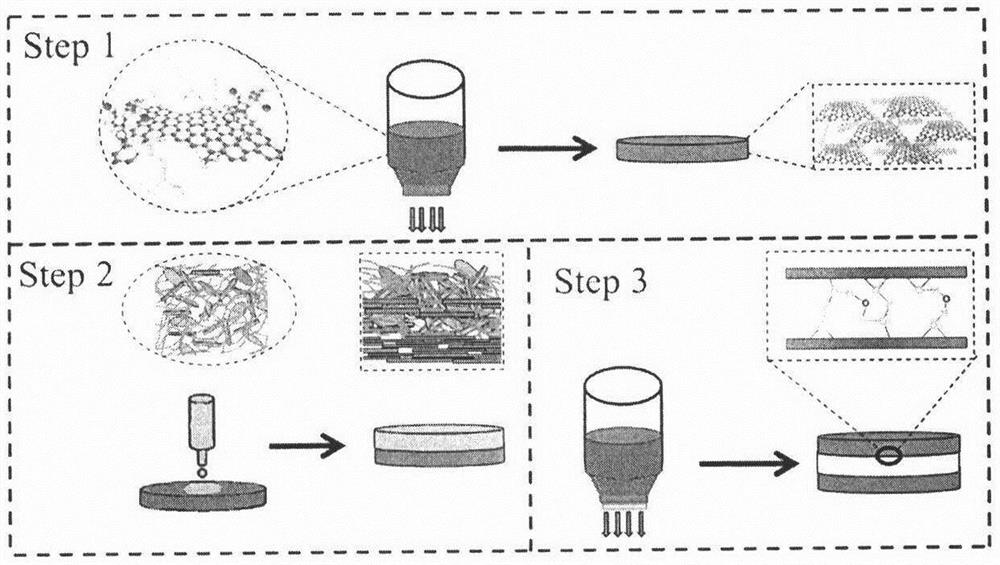

[0029] A method for preparing a phase-change energy storage composite film with a sandwich sandwich structure, comprising the following steps:

[0030] (1) Drop the polyethylene glycol methacrylate monomer of 10mmol into the graphene oxide dispersion (1mgmL -1 ), followed by the addition of nitric acid solution (1mg mL -1 ), the polymerization process was carried out at 60°C under nitrogen protection for 8h, and finally the original suspension was centrifuged and washed 5 times to remove unreacted monomer or residual homopolymer.

[0031] (2) Dissolve 1.54g of poly(ethylene-g-maleic anhydride) in toluene, add 5.41g of stearyl alcohol, stir until completely dissolved, then add p-toluenesulfonic acid as a catalyst, and react at 80°C under nitrogen protection for 8 -10h. After the reaction, the product was precipitated in distilled water and filtered to obtain a crude product. After repeated washing four times in anhydrous methanol, it was dried in a vacuum oven at 50°C to con...

Embodiment 2

[0038] Adjustment Example 1, poly(ethylene-g-maleic anhydride) stearyl alcohol and polyethylene glycol methacrylate modified graphene oxide mixed dispersion liquid is changed into 2mL drop coating volume on base film, other conditions Same as in Example 1, the properties of the prepared sandwich composite membrane are shown in Table 1.

Embodiment 3

[0040] Adjustment Example 1, poly(ethylene-g-maleic anhydride) stearyl alcohol and polyethylene glycol methacrylate modified graphene oxide mixed dispersion is changed into 3mL drop coating volume on the base film, other conditions Same as in Example 1, the properties of the prepared sandwich composite membrane are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com