Method for preparing D-pantoic acid

A pantothenic acid and dinucleotide technology, applied in fermentation and other directions, can solve the problems of great limitation and low cost, achieve high yield, simplify the extraction process, and facilitate large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1, NADH reductase preparation D-pantoic acid activity screening assay

[0025] Dissolve ketopantoic acid, NADH and NADH reductase protein solution (NADH reductase purchased from Tianjin Gong Microbial Technology Co., Ltd. for amino acid reduction reaction, product number is GWOR001-GWOR096, a total of 96 different NADH reductases) In 20 mM (pH 7.5) phosphate buffer, the quantification is 1 mL. The concentration of ketopantoic acid in the reaction system was 100 mM, the concentration of NADH in the reaction system was 1 mM, and the concentration of NADH reductase protein solution was 1 mg / mL.

[0026] After online monitoring with a spectrophotometer (instrument model: UV-1800PC) for 5 min, the enzyme activity was calculated according to the extinction coefficient (6.22 cm-1mmol-1) of NADH at 340 nm. It was found that among the 96 different NADH reductases tested, GWOR005 enzyme had the highest activity in catalyzing the reaction of NAD and ketopantoate to genera...

Embodiment 2

[0027] Embodiment 2, use NADH reductase to prepare D-pantoic acid

[0028] Based on the results of Example 1, the following experiments were further carried out.

[0029] Reaction system (100 ml): composed of reaction solution, ketopantoic acid, NADH reductase and NADH.

[0030] Among them, the reaction solution: 0.5 M Tris-HCl (pH 8.0), 0.6 M glucose, 0.5 mg / mL glucose dehydrogenase; the concentration of ketopantoic acid in the reaction system is 500 mM; NADH reductase: use such as The GW005 commercial enzyme used in Example 1 (purchased from Tianjin Gong Microbiology Technology Co., Ltd.) had a concentration of 1 mg / mL in the reaction system; the concentration of NADH in the reaction system was 1 mM.

[0031] Reaction conditions: 30°C, 200 rpm for 12 hours.

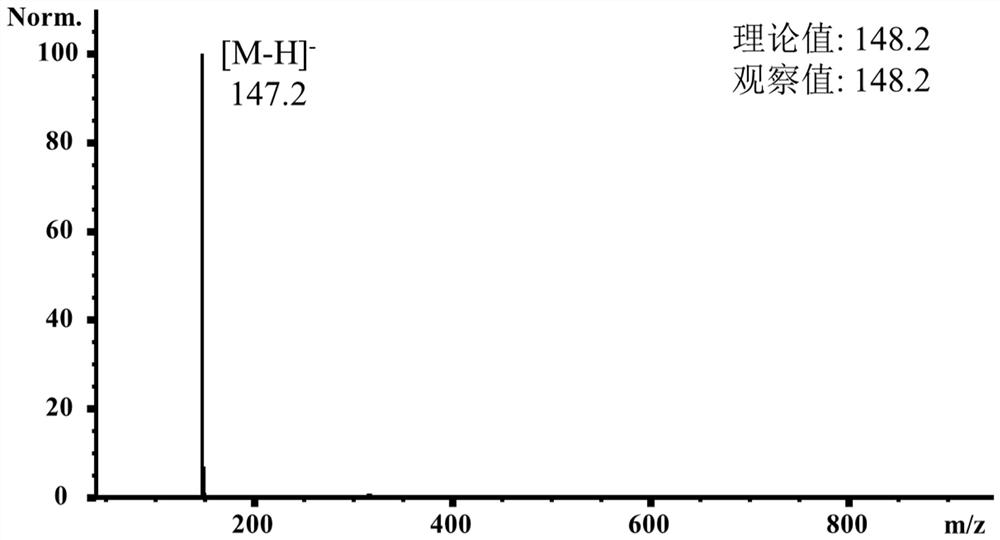

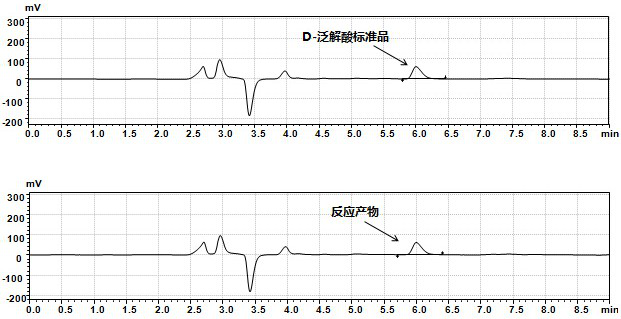

[0032] Product detection: After the reaction was completed, the reaction system was diluted 10 times, and the product concentration was detected by HPLC.

[0033] HPLC chromatographic conditions: Instrument model: Sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com