Preparation process of capsules for treating antral gastritis

A preparation process, a technology for antral gastritis, applied in the field of capsule preparation technology, can solve problems such as insufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] see Figure 1-12 As shown, the present embodiment is a preparation process for capsules for treating gastritis, and the capsules for treating gastritis include the following components in parts by weight:

[0067] 25 parts of gallnut, 12.5 parts of malt, 12.5 parts of grain buds, 80 parts of astragalus, 80 parts of white peony root, 80 parts of jujube, 12.5 parts of licorice, 12.5 parts of cassia twig, 35 parts of Cyperus cyperi, 35 parts of poria cocos, 23 parts of turmeric, 18 parts of perilla stalk, 18 parts of green peel, 18 parts of tangerine peel, 16 parts of Chuandongzi, 16 parts of Bupleurum, 20 parts of Yuanhu, 16 parts of amomum, 12.5 parts of peach kernel, 16 parts of pinellia;

[0068] The capsule for treating gastritis is prepared by the following steps:

[0069] Step 1: Mix gallnuts, malt, grain buds, astragalus, white peony root, jujube, licorice, cinnamon sticks, incense symbols, poria cocos, turmeric, perilla stems, green peel, tangerine peel, Chuandon...

Embodiment 2

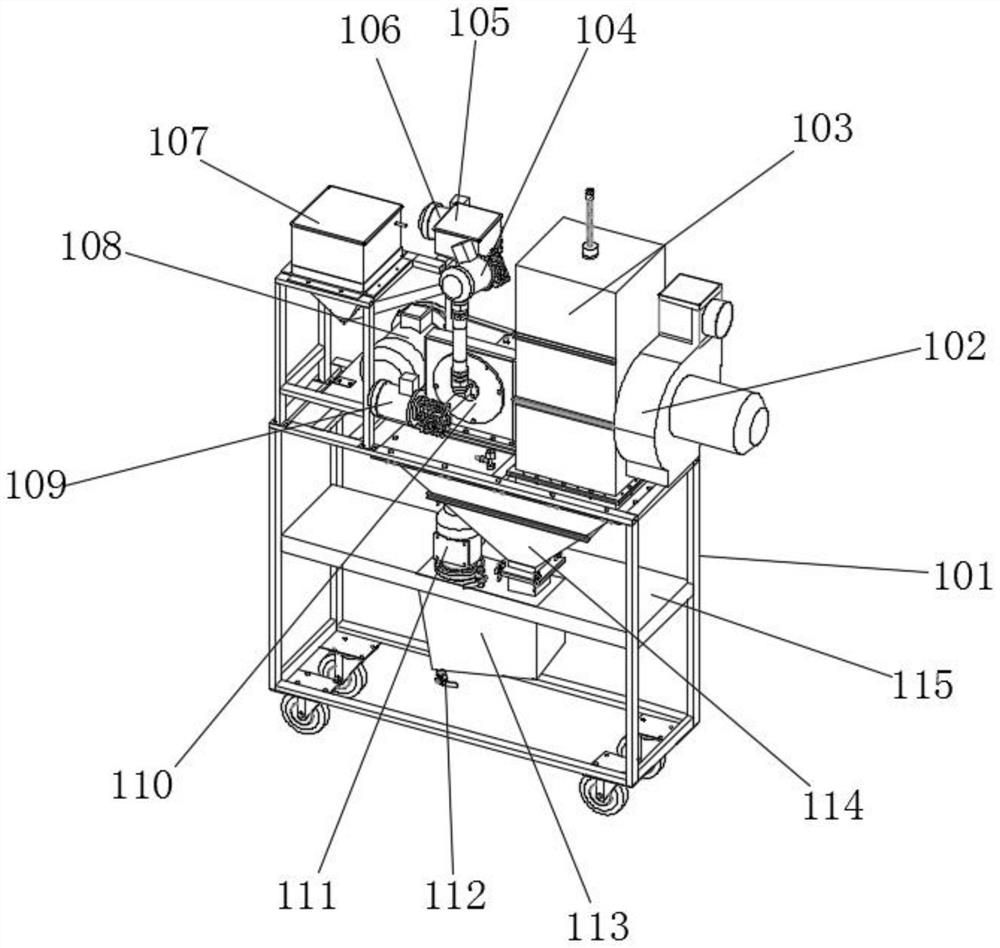

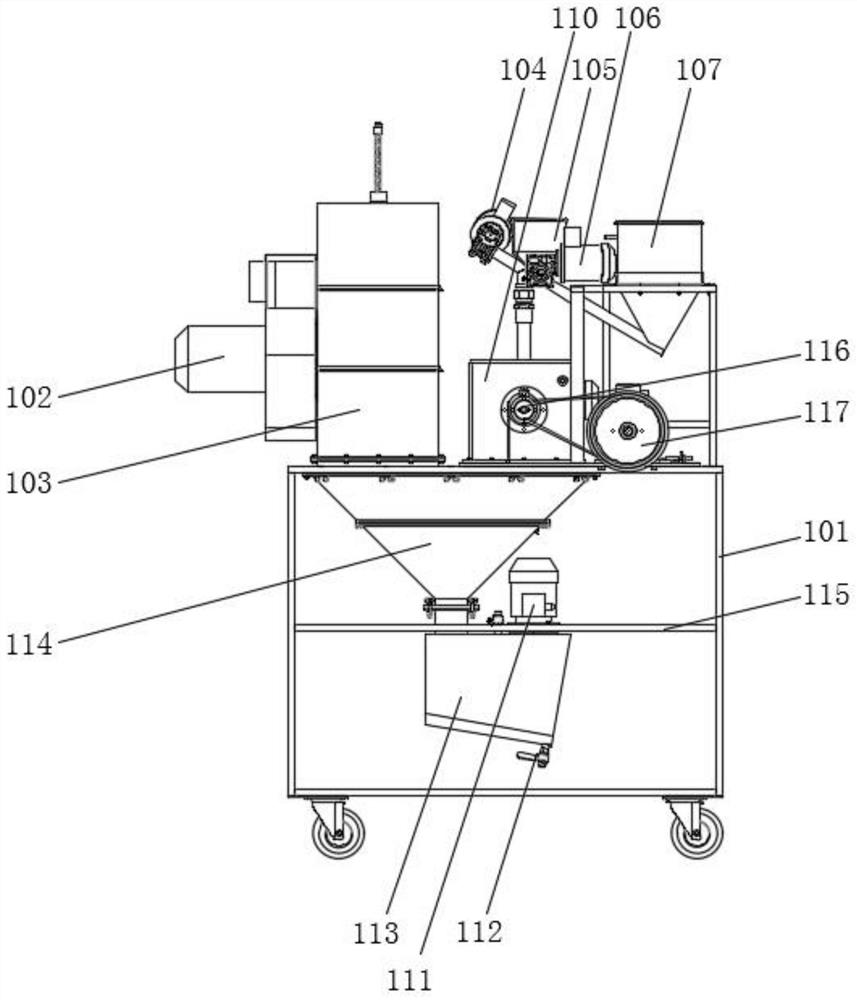

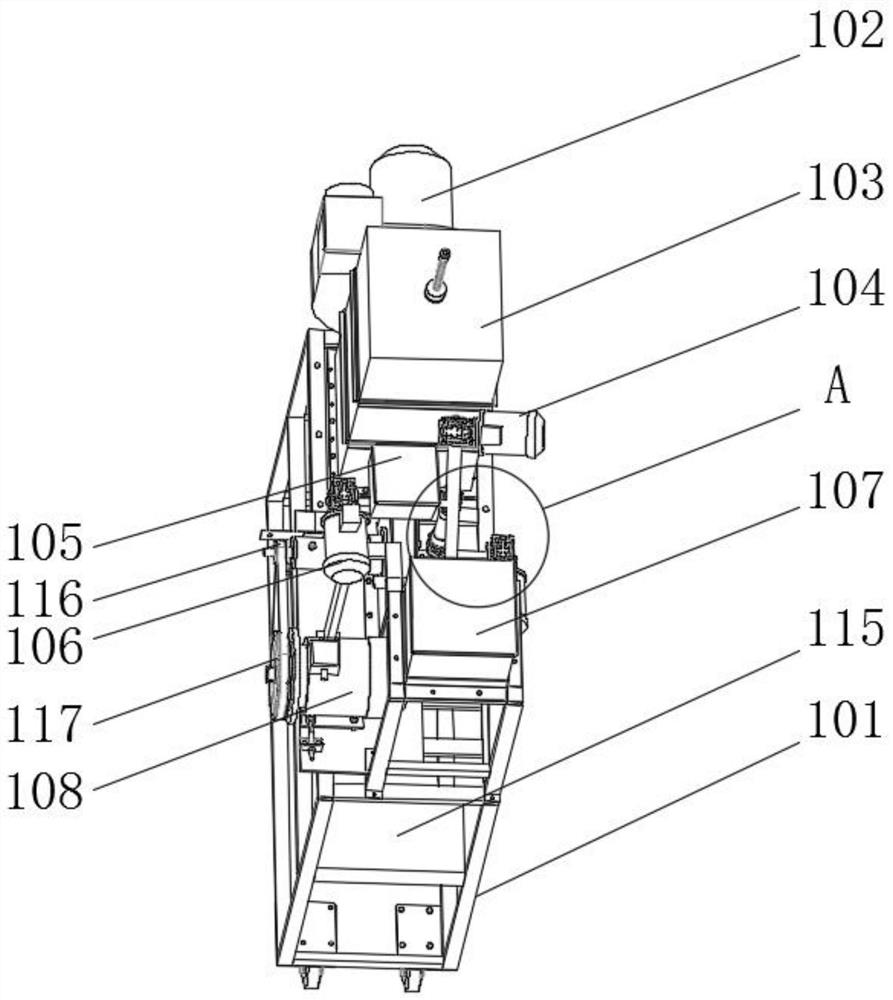

[0079] see Figure 1-12 As shown, the ultrafine pulverization equipment in this embodiment includes a mounting frame 101, a pulverizing mechanism 110, and a winnowing box 103. One end of the top of the mounting frame 101 is equipped with a winnowing box 103, and one side of the winnowing box 103 is connected. To the air inlet of the induced draft fan 102, the top end of the installation frame 101 away from the winnowing box 103 is equipped with a material feed hopper 107 through a bracket, and the bottom end of the material feed hopper 107 is obliquely equipped with a first feed pipe 118, so One end of the first feed pipe 118 away from the material feed hopper 107 is connected to the output shaft of the first conveying motor 104 through a transmission box 122, and a second feed pipe 119 is installed on one side of the first feed pipe 118, so The top of the second feed pipe 119 is vertically equipped with a liquid nitrogen storage tank 105, and the end of the second feed pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com