Immersion type reaction assembly for nitrogen recovery of high-ammonia-nitrogen-content wastewater and recovery method

A high-ammonia-nitrogen, immersion-type technology, applied in chemical instruments and methods, animal husbandry wastewater treatment, water pollutants, etc., can solve problems such as difficult cost control, complicated process, and increased dosage of chemicals, and achieve no risk of membrane pollution, production The effect of low cost and fast recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

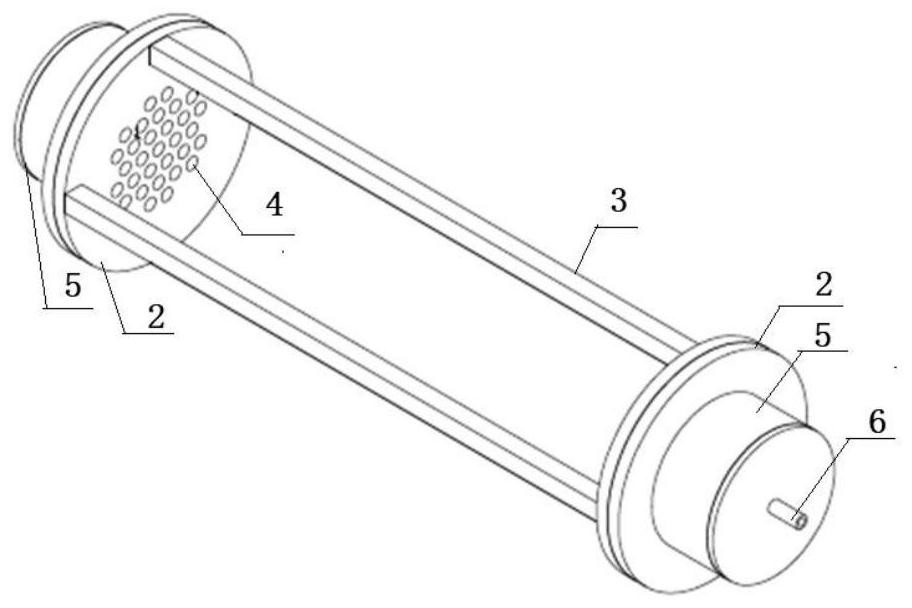

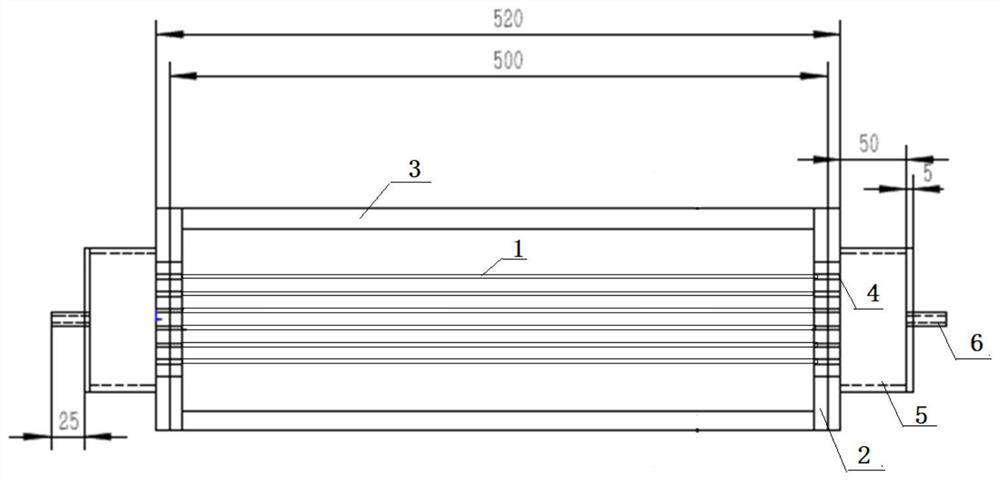

[0038] An immersion reaction assembly for nitrogen recovery from waste water with high ammonia nitrogen content, comprising a hydrophobic membrane tube 1 with both ends open and a reaction frame for fixing the hydrophobic membrane tube. Such as figure 1 As shown, the reaction frame includes two symmetrically arranged end plates 2, which are connected by a connecting frame 3, and a plurality of through holes 4 are arranged on the end plates, and the two end plates The outer sides of each are provided with connecting chambers 5, and thin tubes 6 are arranged on the connecting chambers, and the thin tubes communicate with the inside of the connecting chambers. Such as figure 2 , 3 As shown, the two ends of the hydrophobic membrane tube 1 are respectively fixed in the through holes of the two end plates, the diameters of all the through holes on the end plates are consistent with the outer diameters of the hydrophobic membrane tubes, and the membrane tubes are connected to the ...

Embodiment 2

[0043] A method for recovering nitrogen from waste water with high ammonia nitrogen content, comprising the following steps:

[0044] Configure the ammonia nitrogen extractant: configure the ammonia nitrogen extractant, and then put the configured ammonia nitrogen extractant in the extractant container;

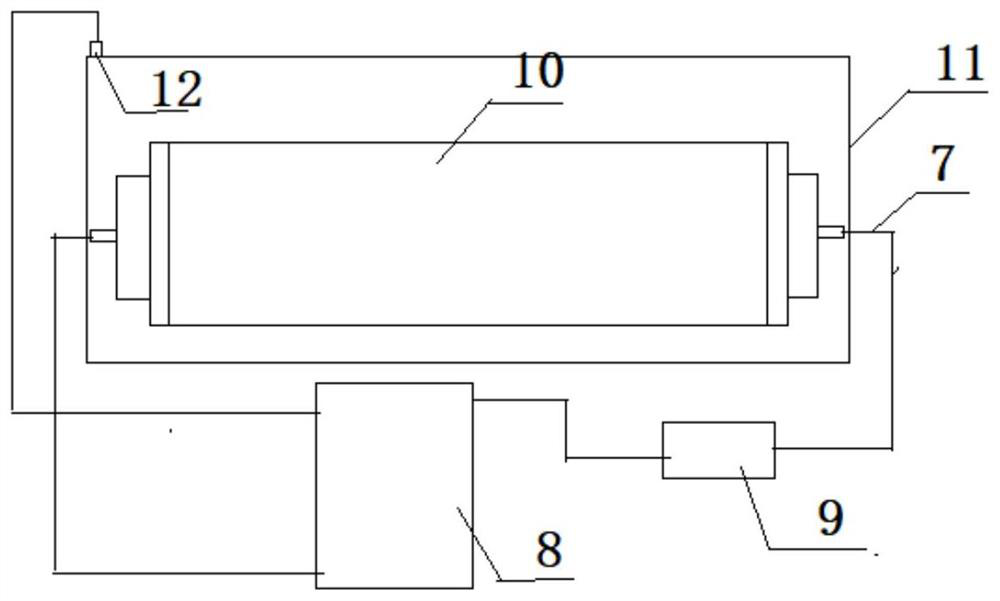

[0045] Build a recycling system: such as image 3 As shown, the thin tube 6 at one end of the submerged reaction assembly described in the above-mentioned embodiment 1 is connected to the liquid outlet of the extractant container 8 through an acid-resistant connecting pipe, and the thin tube at the other end of the submerged reaction assembly is connected through an acid-resistant connecting pipe. Connect with the liquid inlet of circulation pump 9, the liquid outlet of described circulation pump 9 is connected with the liquid inlet of extractant container 8 by acid-resistant connecting pipe, makes extractant circulate in submerged reaction module, forms extractant can Circu...

Embodiment 3

[0051] A method for recovering nitrogen from waste water with high ammonia nitrogen content, comprising the following steps:

[0052] Configure the ammonia nitrogen extractant: configure the ammonia nitrogen extractant, and then put the configured ammonia nitrogen extractant in the extractant container;

[0053] Build a recycling system: such as Figure 4 As shown, the thin tube 6 at one end of the submerged reaction assembly 10 described in the above-mentioned embodiment 1 is connected to the liquid outlet of the extractant container 8 through an acid-proof connecting pipe 7, and the thin tube at the other end of the submerged reaction assembly is connected through an acid-resistant connecting pipe 7. The connecting pipe is connected to the liquid inlet of the circulating pump 9, and the liquid outlet of the circulating pump 9 is connected to the liquid inlet of the extractant container 8 through an acid-resistant connecting pipe, so that the extractant circulates in the subm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com