Method for passivating perovskite and preparation process of perovskite solar cell

A solar cell and perovskite technology, applied in the field of solar cells, can solve problems such as synergistic perovskite solar cells, perovskite degradation, and impact on charge transfer, and achieve improved charge transfer performance, prevention of degradation, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Adopt tetraethylhexafluoroammonium phosphate (TEA) as the perovskite solar cell of passivating agent and preparation method thereof:

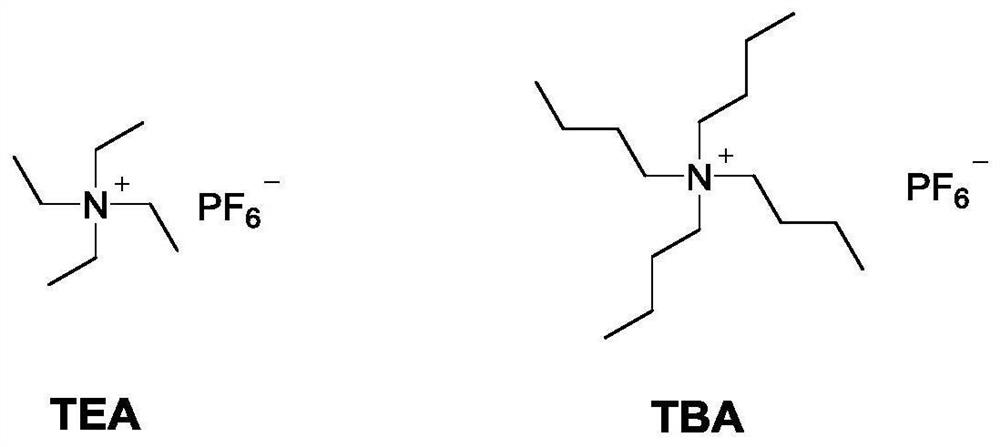

[0046] The cell structure of the perovskite solar cell is FTO / c-TiO 2 / m-TiO 2 / perovskite / TEA / Spiro-OMeTAD / Au. Wherein, the structural formula of the TEA is as follows:

[0047]

[0048] The preparation process of the perovskite solar cell is:

[0049] (1) FTO (fluorine-doped tin dioxide) conductive glass was cut into 25mm x 15mm glass substrates and etched using zinc powder and hydrochloric acid chemistry. The etched glass substrates were ultrasonically cleaned in deionized water, acetone, and ethanol for 15 minutes, and then placed in a UV-ozone machine for 15 minutes.

[0050] (2) Using the spray pyrolysis method, spray an isopropanol solution of 0.2M titanium tetraisopropoxide and 2M acetylacetone on the FTO glass substrate heated to 500°C to form a thin layer of TiO 2 Dense layer; 150mg / ml nano-TiO 2 ethanol solution spin-...

Embodiment 2

[0057] Adopt tetrabutyl ammonium hexafluorophosphate (TBA) as the perovskite solar cell of passivating agent and preparation method thereof:

[0058] The cell structure of the perovskite solar cell is FTO / c-TiO 2 / m-TiO 2 / perovskite / TBA / Spiro-OMeTAD / Au. Wherein, the structural formula of the TBA is as follows:

[0059]

[0060] The preparation process of the perovskite solar cell is:

[0061] (1) FTO (fluorine-doped tin dioxide) conductive glass was cut into 25mm x 15mm glass substrates and etched using zinc powder and hydrochloric acid chemistry. The etched glass substrates were ultrasonically cleaned in deionized water, acetone, and ethanol for 15 minutes, and then placed in a UV-ozone machine for 15 minutes.

[0062] (2) Using the spray pyrolysis method, spray an isopropanol solution of 0.2M titanium tetraisopropoxide and 2M acetylacetone on the FTO glass substrate heated to 500°C to form a thin layer of TiO 2 Dense layer; 150mg / ml nano-TiO 2 ethanol solution spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com