Perylene diimide assembly doped perovskite solar cell and preparation method thereof

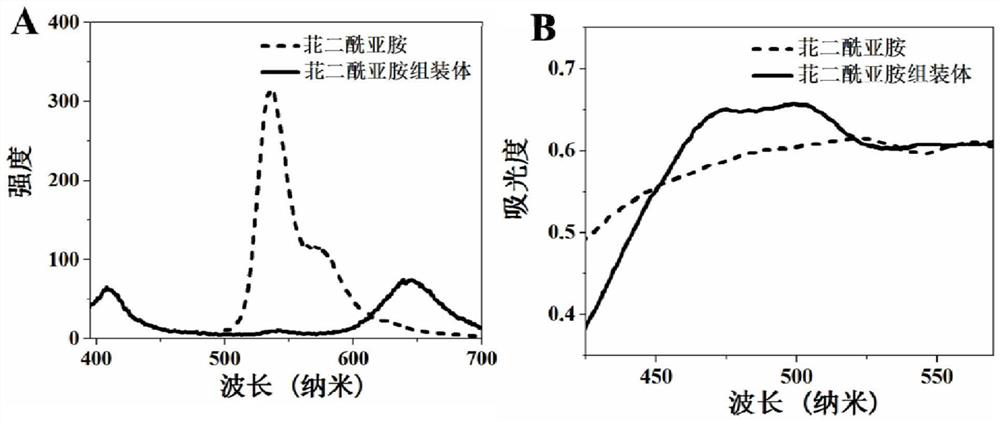

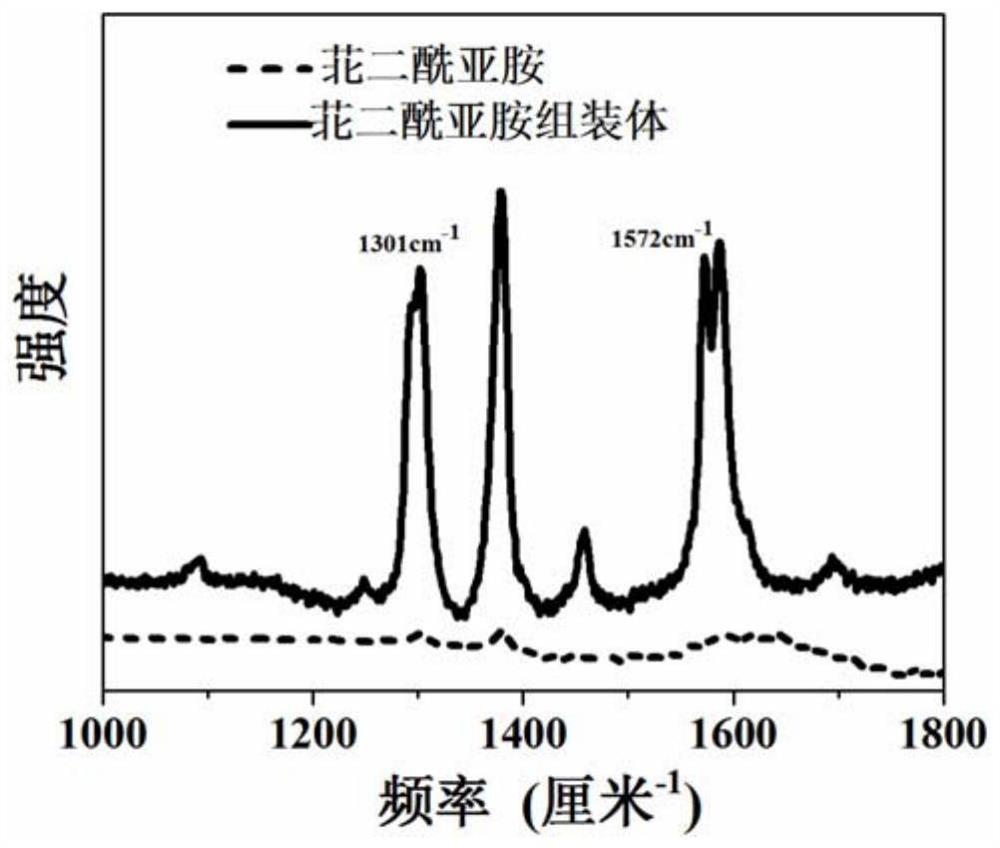

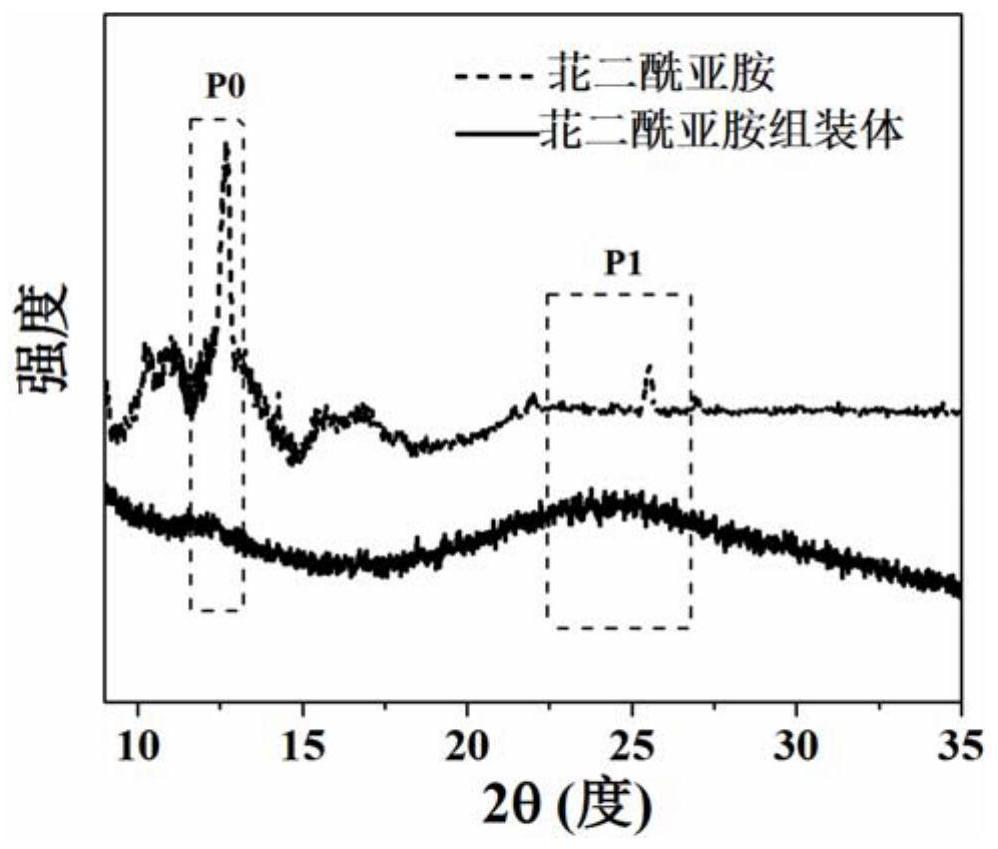

A perylene diimide and solar cell technology, which is applied in the field of solar cell materials, can solve problems such as limiting structural adjustability, and achieve the effects of inhibiting interfacial recombination, improving optical properties and thermal stability, and effective charge transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparation of perylene diimide

[0031] Weigh 1.376g of perylene-3,4,9,10-tetracarboxylic dianhydride, 2.5g of 3-aminopropionic acid and 18g of imidazole, put the three into a round-bottomed flask, and place them in a nitrogen atmosphere at 100°C. Stir and heat for 4h. After the reaction was completed, it was cooled to room temperature and dispersed in 100 ml of ethanol. 300ml of dilute hydrochloric acid was added to it, and the mixture was stirred for 24h. The final product was vacuum filtered through a 0.45 μm membrane and the red solid was collected. Wash with distilled water several times until the pH of the washing solution becomes neutral. The obtained solid was dried under vacuum at 60°C, namely pure perylene diimide powder.

[0032] 2. Preparation of perylene diimide-LDH (ion exchange method)

[0033] Preparation of LDH precursor:

[0034] Weigh magnesium nitrate hexahydrate (3.8461g) and aluminum nitrate nonahydrate (1.8760g) with a molar ratio of 2:1...

Embodiment 2

[0048] 1. Preparation of perylene diimide

[0049] Weigh 1.376g of perylene-3,4,9,10-tetracarboxylic dianhydride, 2.5g of 3-aminopropionic acid and 18g of imidazole, put the three into a round-bottomed flask, and place them in a nitrogen atmosphere at 100°C. Stir and heat for 4h. After the reaction was completed, it was cooled to room temperature and dispersed in 100 ml of ethanol. 300ml of dilute hydrochloric acid was added to it, and the mixture was stirred for 24h. The final product was vacuum filtered through a 0.45 μm membrane and the red solid was collected. Wash with distilled water several times until the pH of the washing solution becomes neutral. The obtained solid was dried under vacuum at 60°C, namely pure perylene diimide powder.

[0050] 2. Preparation of perylene diimide-LDH (co-precipitation intercalation)

[0051] Weigh magnesium nitrate hexahydrate (3.8461g) and aluminum nitrate nonahydrate (1.8760g) with a molar ratio of 2:1 and dissolve them in 200ml t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com