Preparation method of efficient and stable perovskite solar cell

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of adverse effects on the efficiency and long-term stability of perovskite solar cells, complex synthesis routes and purification steps, accelerated moisture/oxygen permeation, etc., so as to improve the device. Good stability, thermal stability and chemical stability, and the effect of inhibiting degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

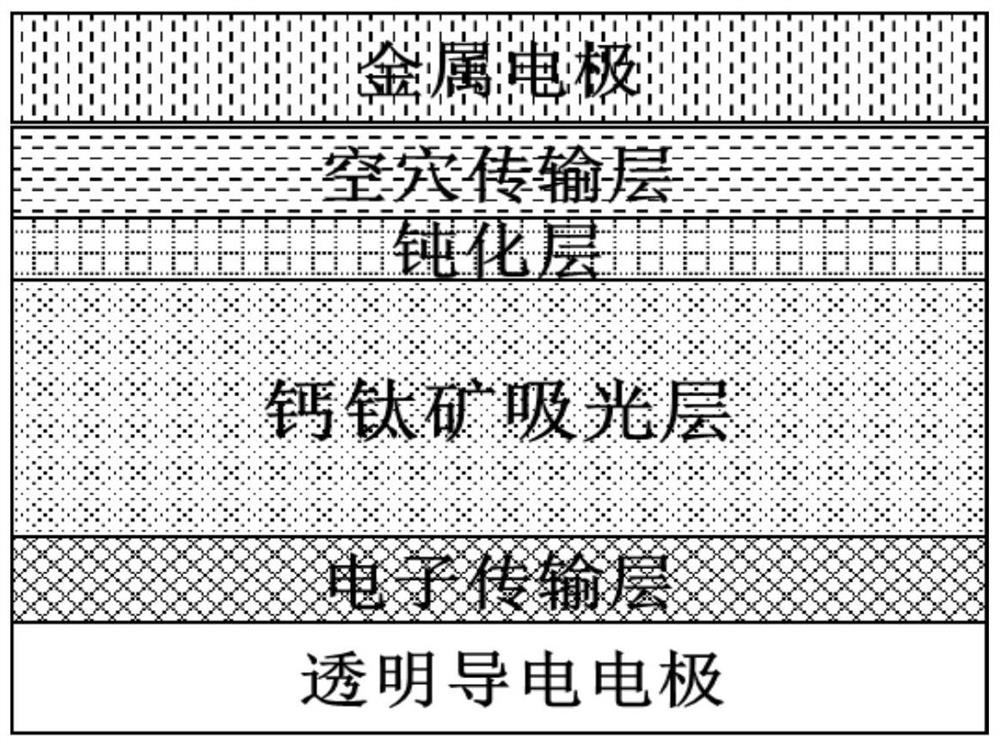

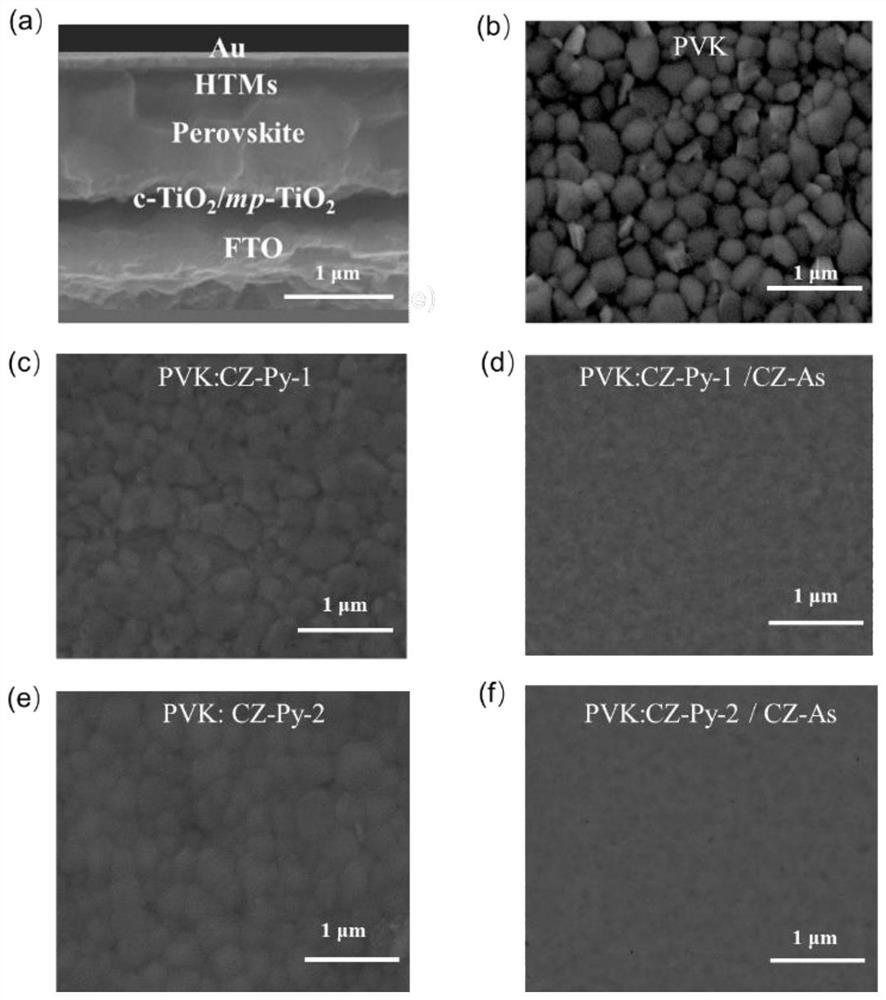

[0052] The preparation method and process of a perovskite solar cell using CZ-Py-1 as a passivation material and CZ-As as a hole transport material:

[0053] The cell structure of the perovskite solar cell is FTO / c-TiO 2 / m-TiO 2 / Perovskite / CZ-Py-1 / CZ-As / Au, the preparation process of the perovskite solar cell is:

[0054] (1) Cut the FTO (fluorine-doped tin dioxide) conductive glass into a glass substrate with a size of 15mm x 15mm, and use an etching machine to etch. The etched glass substrate was ultrasonically cleaned for 30 min in deionized water, acetone and ethanol in sequence, and then placed in a UV-ozone machine for 30 min.

[0055] (2) Using the spray pyrolysis method, spray an isopropanol solution of 0.2M titanium tetraisopropoxide and 2M acetylacetone on the FTO glass substrate heated to 500°C to form a thin layer of TiO 2 Dense layer; 150mg / ml nano-TiO 2 ethanol solution spin-coated on TiO 2 On the dense layer, the rotation speed is controlled to be 5000rpm...

Embodiment 2

[0071] The preparation method and process of perovskite solar cells using CZ-Py-2 as passivation material and CZ-As as hole transport material:

[0072] The cell structure of the perovskite solar cell is FTO / c-TiO 2 / m-TiO 2 / Perovskite / CZ-Py-2 / CZ-As / Au, the preparation process of the perovskite solar cell is:

[0073] (1) Cut the FTO (fluorine-doped tin dioxide) conductive glass into a glass substrate with a size of 15mm x 15mm, and use an etching machine to etch. The etched glass substrates were ultrasonically cleaned in deionized water, acetone, and ethanol for 30 min, and then placed in a UV-ozone machine for 30 min.

[0074] (2) Using the spray pyrolysis method, spray an isopropanol solution of 0.2M titanium tetraisopropoxide and 2M acetylacetone on the FTO glass substrate heated to 500°C to form a thin layer of TiO 2 Dense layer; 150mg / ml nano-TiO 2 ethanol solution spin-coated on TiO 2 On the dense layer, the rotation speed is controlled to be 5000rpm, and the spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com