MXene/Ni composite material as well as preparation method and application thereof

A composite material and mixed liquid technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problem that the wave absorbing ability needs to be improved, and achieve excellent wave absorbing ability, increase specific surface area, and good wave absorbing ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the MXene / Ni composite material of the present embodiment may further comprise the steps:

[0035] (1) Ti 3 C 2 T x Preparation of materials:

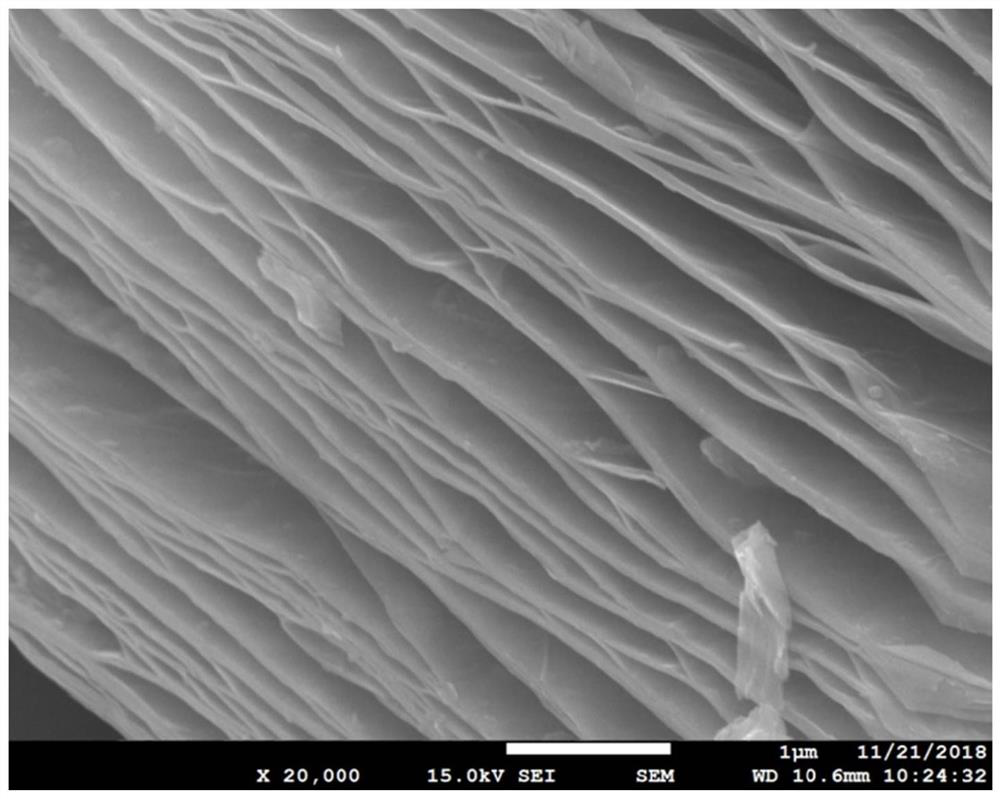

[0036] Take 3g Ti 3 AlC 2 The material was immersed in 30mL of hydrofluoric acid (42% by mass), and stirred magnetically for 3h to fully react; after that, it was centrifuged at 3500rpm for 1h, washed with deionized water until the pH of the washing solution was greater than or equal to 6, and then the washed sample was Freeze-dried to obtain a two-dimensional layered structure of Ti 3 C 2 T x Material.

[0037] (2) Preparation by hydrothermal method:

[0038] Weigh 0.3g of nickel chloride hexahydrate and 0.1g of trisodium citrate and dissolve them in a mixture of 1,2 propylene glycol and glycerin (7.5mL each of 1,2 propylene glycol and glycerol), stir magnetically for 1h; then add 0.8g anhydrous sodium acetate, stir for 30min; then add 0.27g Ti 3 C 2 T x Materials, 1.5mL hydrazine hydrate,...

Embodiment 2

[0040]The preparation method of the MXene / Ni composite material of the present embodiment may further comprise the steps:

[0041] (1) Ti 3 C 2 T x Preparation of materials: same as Example 1.

[0042] (2) Preparation by hydrothermal method:

[0043] Weigh 0.2g of nickel chloride hexahydrate and 0.07g of trisodium citrate and dissolve them in a mixture of 1,2 propylene glycol and glycerol (5mL each of 1,2 propylene glycol and glycerol), stir magnetically for 1h; then add 0.53 g anhydrous sodium acetate, stirred for 30min; then added 0.27g Ti 3 C 2 T x Materials, 1mL hydrazine hydrate, magnetically stirred for 5min to obtain a mixed solution; transfer the mixed solution to a reaction kettle, and conduct a hydrothermal reaction at 140°C for 15h; and anhydrous ethanol for 5 times respectively; finally put it into a blast drying oven, and dry it at 50°C for 24 hours to obtain it.

Embodiment 3

[0045] The preparation method of the MXene / Ni composite material of the present embodiment may further comprise the steps:

[0046] (1) Ti 3 C 2 T x Preparation of materials: same as Example 1.

[0047] (2) Preparation by hydrothermal method:

[0048] Weigh 0.15g of nickel chloride hexahydrate and 0.05g of trisodium citrate and dissolve them in a mixture of 1,2 propylene glycol and glycerin (3.75mL each of 1,2 propylene glycol and glycerol), stir magnetically for 1h; then add 0.4g anhydrous sodium acetate, stir for 30min; then add 0.27g Ti 3 C 2 T x Materials, 0.75mL hydrazine hydrate, magnetically stirred for 10min to obtain a mixed solution; transfer the mixed solution to a reaction kettle, and conduct a hydrothermal reaction at 140°C for 15h; Wash with water and absolute ethanol 5 times respectively; finally put it into a forced air drying oven and dry at 80°C for 18 hours to obtain the final product.

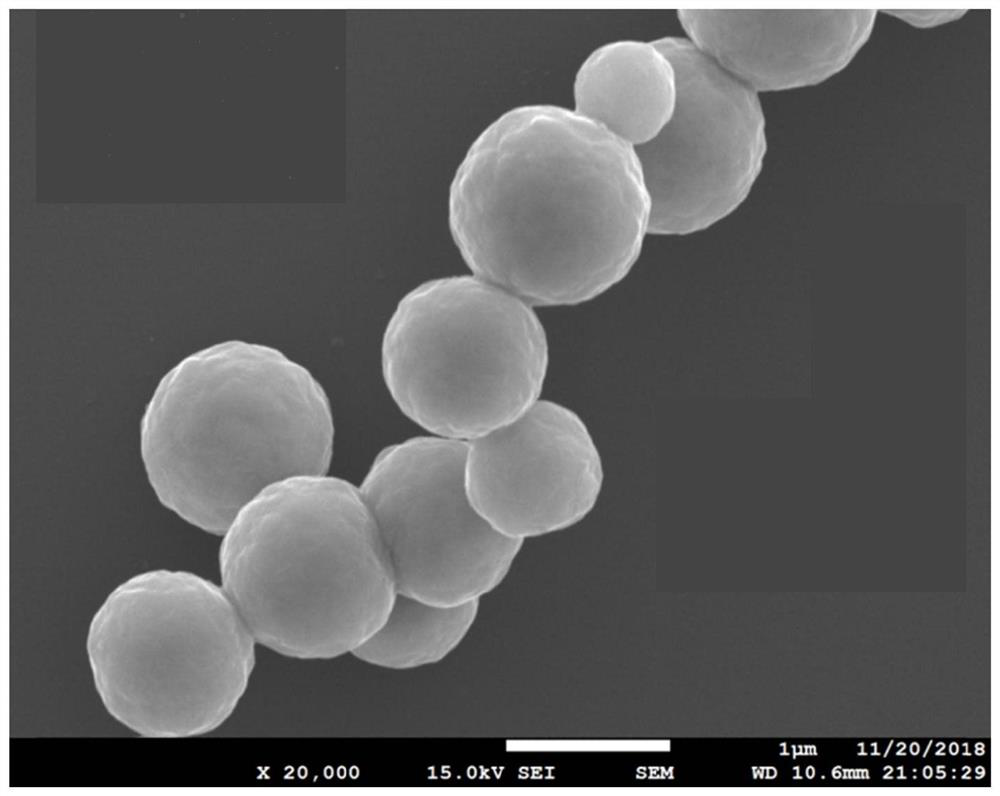

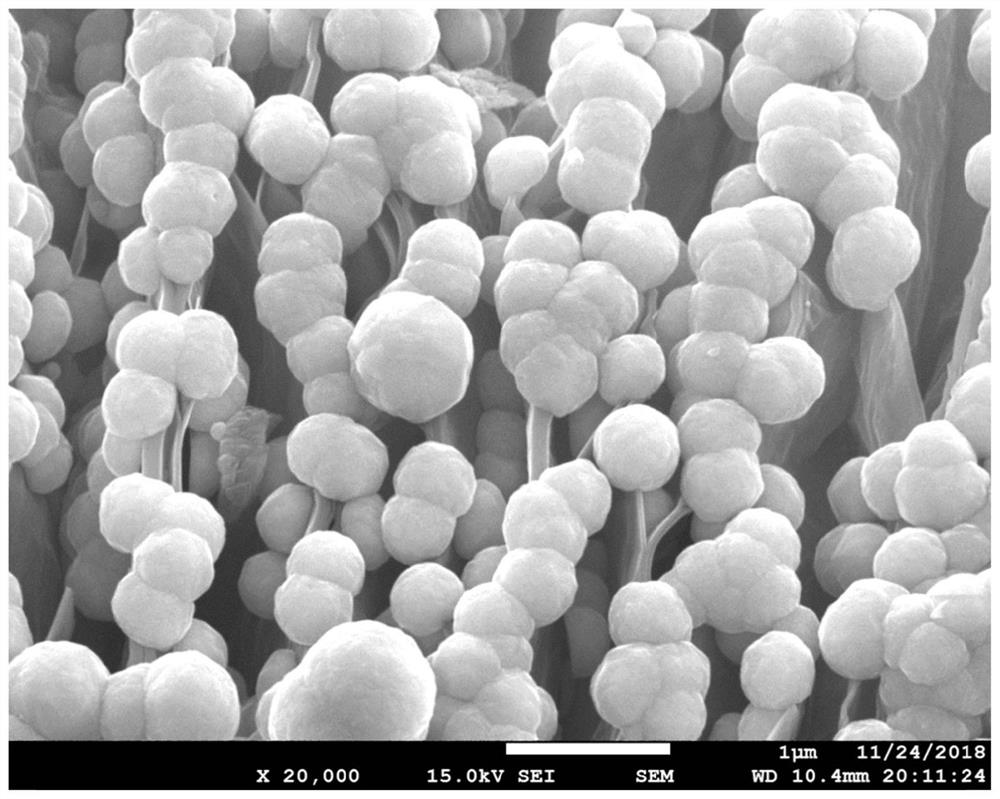

[0049] Two, the specific embodiment 1-3 of MXene / Ni composite m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com