Preparation method of oily sewage treatment filter material modifier

A technology of modifier and oily sewage, which is applied in the field of preparation of filter material modifiers for oily sewage treatment, which can solve the problems of difficult filter material, increased filter resistance, increased filter pressure, etc., and achieve good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

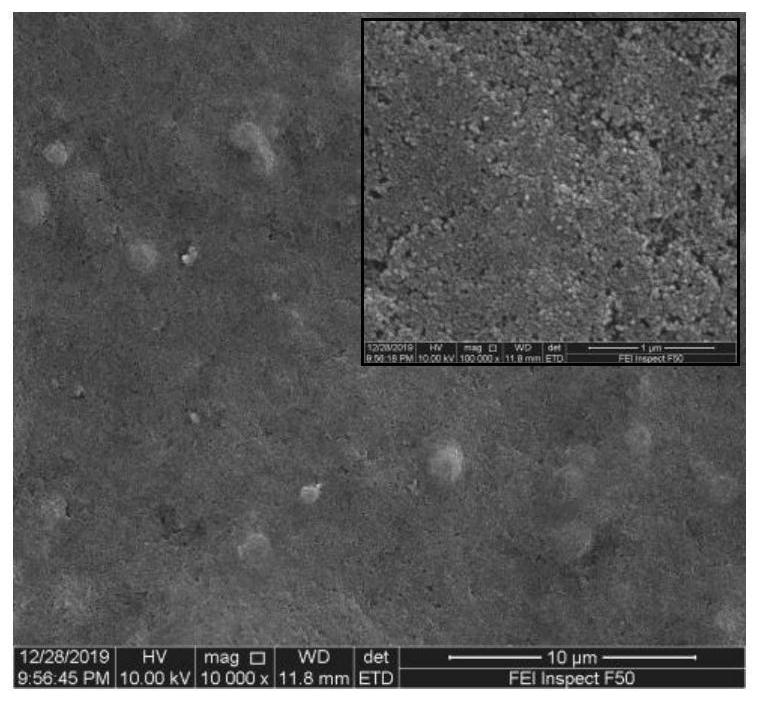

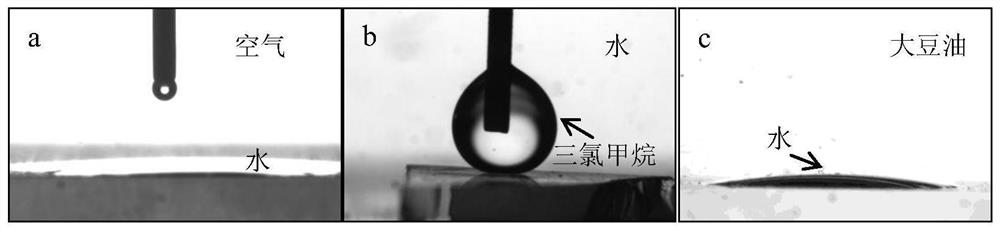

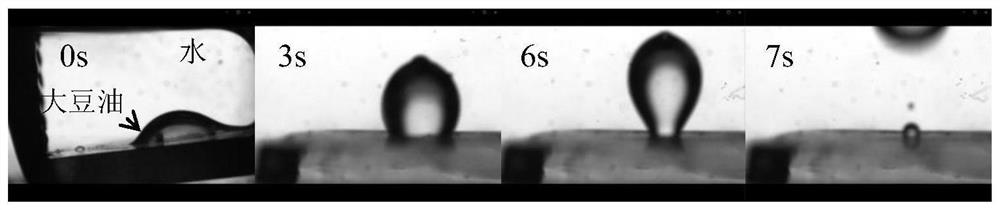

[0038] 10 g of microcrystalline cellulose with a size of ~20 microns was added to 100 ml of sulfuric acid solution with a volume concentration of 64%, and mechanically stirred at 45° C. for 4 hours to fully hydrolyze it. Add water to wash off excess acid by centrifugation, and then add water to dilute until it is just neutral to obtain an aqueous solution of cellulose nanocrystals. Add 5g of acidic chain silica sol (pH=2~4, diameter 10~15nm, chain length 80~120nm, mass concentration 15~16%) into 20g cellulose nanocrystal aqueous solution, at 50°C at 300r / min Stir magnetically at a high speed for 1 hour, then add 0.75g of water-based epoxy resin, 0.75g of acrylic resin, and 0.1% of N,N-methylenebisacrylamide curing agent, heat to 50°C and fully react for 24 hours, then spray on the glass On the chip, after drying at 80 °C, a superhydrophilic coating was obtained. The surface of the coating is dense and smooth as figure 1 As shown, it is superhydrophilic in air ( figure 2 a)...

Embodiment 2

[0040] 20 g of microcrystalline cellulose with a size of ~50 microns was added to 200 ml of sulfuric acid solution with a volume concentration of 50%, and mechanically stirred at 60° C. for 6 hours to fully hydrolyze it. Add water to wash off excess acid by centrifugation, and then add water to dilute until it is just neutral to obtain an aqueous solution of cellulose nanocrystals. Add 15g of acidic spherical silica sol (pH=2~4, diameter 4~7nm, mass concentration 20%) into 3g of cellulose nanocrystal aqueous solution and 17g of water, stir magnetically at a speed of 300r / min at 50°C for 1h, then Add 0.75g of water-based polyurethane, 0.75g of water-based epoxy resin, and 0.1% of N,N-methylenebisacrylamide curing agent, heat to 50°C and fully react for 24 hours, then spray it on a glass slide, and after drying at 80°C, Get a super-hydrophilic coating. It is super-hydrophilic in air, with a water contact angle of 8°. It is super oleophobic under water, and the underwater conta...

Embodiment 3

[0042] 5 g of microcrystalline cellulose with a size of ~80 μm was added to 50 ml of hydrochloric acid solution with a volume concentration of 64%, and mechanically stirred at 30° C. for 6 h to fully hydrolyze it. Add water to wash off excess acid by centrifugation, and then add water to dilute until it is just neutral to obtain an aqueous solution of cellulose nanocrystals. Add 15g of alkaline spherical silica sol (pH=9~11, diameter 8-11nm, mass concentration 20%) into 3g cellulose nanocrystal aqueous solution and 17g water, and stir magnetically at 300r / min at 50°C for 1h, Then add 1.5g of water-based epoxy resin and 0.1% of divinylbenzene curing agent, heat to 50°C and fully react for 12h, then spray it on a glass slide and dry at 80°C to obtain a super-hydrophilic coating. It is super-hydrophilic in air, with a water contact angle of 12°. It is super oleophobic under water, and the underwater contact angle is 149°. It is super-hydrophilic under oil, and the water contact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com