Hindered amine light stabilizer intermediate and preparation method of hindered amine light stabilizer

A hindered amine light stabilizer and intermediate technology, which is applied in the field of polymer material functional additives, can solve the problems of large amount of formaldehyde-containing wastewater and affect product purity, and achieve reduced post-treatment procedures, short melting range, and simplified reactions Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

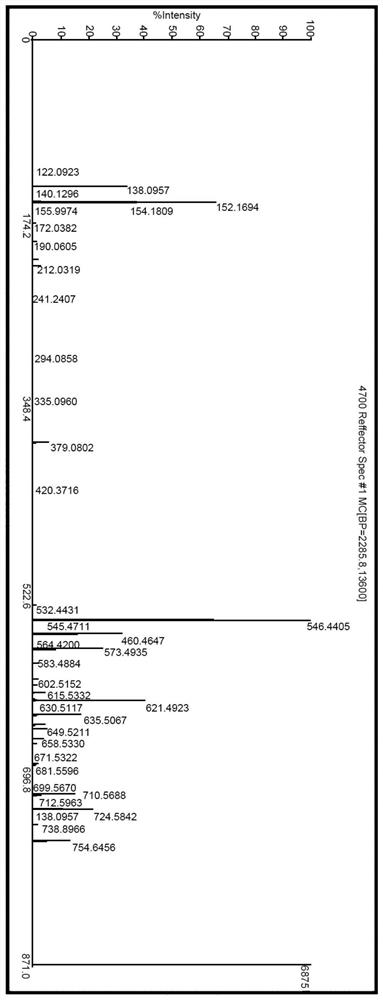

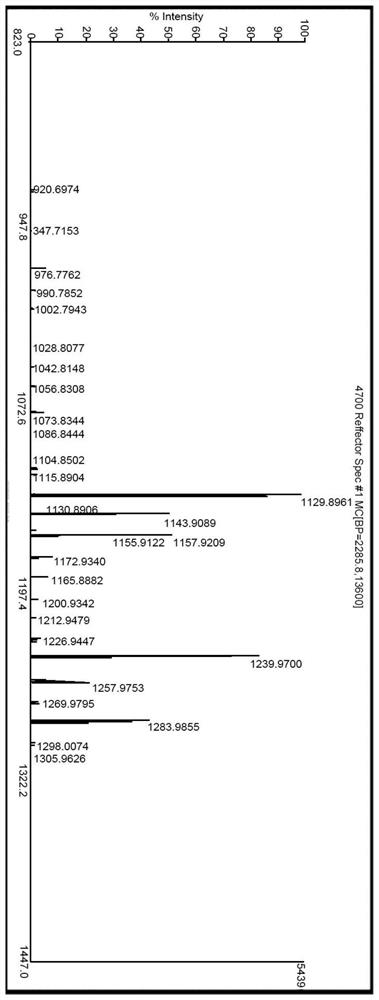

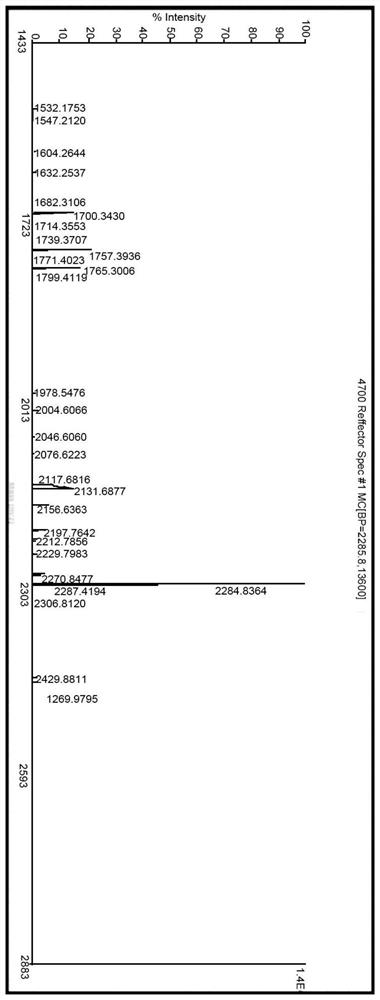

[0031] In order to solve the above problems, the present invention provides a preparation method of a hindered amine light stabilizer intermediate, the hindered amine light stabilizer intermediate 2-chloro-4,6-bis(N-butyl-N-1,2 ,2,6,6-pentamethyl-4-piperidinylamino)-1,3,5-triazine, whose structural formula is The preparation method comprises the following steps: in the presence of hydrogen, 1,2,2,6,6-pentamethyl-4-piperidone and n-butylamine undergo hydrogenation substitution reaction to obtain intermediate 1, intermediate 1 has the following structure:

[0032]

[0033] Substitution of intermediate 1 with cyanuric chloride gave 2-chloro-4,6-di(N-butyl-N-1,2,2,6,6-pentamethyl-4-piperidinyl amino)-1,3,5-triazine.

[0034] Above-mentioned reaction route is as follows:

[0035]

[0036] Different from the need to use formaldehyde or formic acid for N-methylation in the traditional preparation process, the present invention uses 1,2,2,6,6-pentamethyl-4-piperidone as the ...

Embodiment 1

[0055] Put 33.8g (0.2mol) 1,2,2,6,6-pentamethyl-4-piperidone, 14.6g (0.2mol) n-butylamine, 5.0g skeleton nickel catalyst and 200ml toluene into the autoclave , replace the air with nitrogen and hydrogen successively, react at 90°C and 3.0 MPa until the hydrogen pressure no longer decreases, the reaction is completed, and the catalyst is removed by filtration to obtain the reaction solution of intermediate 1;

[0056] Dissolve 18.4g (0.1mol) of cyanuric chloride in 300ml of toluene, cool down in an ice-water bath to below 10°C, add the reaction solution of Intermediate 1 dropwise, after the dropwise addition, stir for 1 hour, then add dropwise 36ml of 20% hydrogen Sodium oxide aqueous solution, wherein the molar ratio of sodium hydroxide to intermediate 1 is 1.1:1, and the molar ratio of cyanuric chloride to intermediate 1 is 1:2; the temperature is raised to 60°C for 8 hours, and the liquid is separated after the reaction, organic The phase was washed with water to obtain 2-ch...

Embodiment 2

[0061] Put 33.8g (0.2mol) 1,2,2,6,6-pentamethyl-4-piperidone, 15.3g (0.21mol) n-butylamine, 6.0g skeleton nickel catalyst and 300ml xylene into the autoclave In the process, the air was replaced with nitrogen and hydrogen successively, and the reaction was carried out at 100°C and 4.0 MPa until the hydrogen pressure no longer decreased. After the reaction was completed, the catalyst was removed by filtration to obtain the reaction solution of intermediate 1;

[0062] Dissolve 18.4g (0.1mol) of cyanuric chloride in 200ml of xylene, cool down in an ice-water bath to below 10°C, add the reaction solution of intermediate 1 dropwise, after the dropwise addition, stir for 1 hour, then add dropwise 20.5ml of 30 % sodium hydroxide aqueous solution, wherein the molar ratio of sodium hydroxide to intermediate 1 is 1.1:1, and the molar ratio of cyanuric chloride to intermediate 1 is 1:2; the temperature is raised to 80°C for 12 hours, and the liquid is separated after the reaction , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com