Artificial macadam for road construction and preparation method thereof

A kind of artificial and road technology, applied in the field of artificial gravel for road construction and its preparation, can solve the problems of unstable sources of construction waste, complex and changeable components, and substandard compressive strength, so as to avoid environmental and safety hazards, The effect of reducing consumption and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

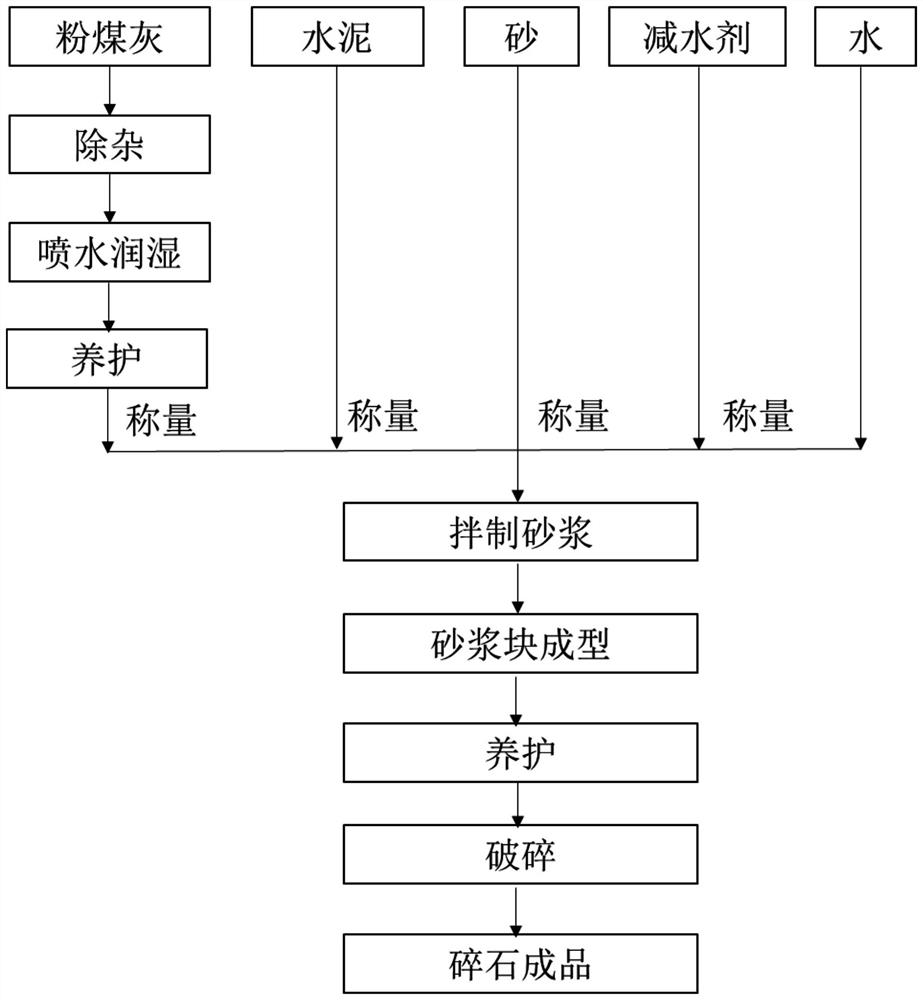

[0027] The invention provides a method for preparing artificial gravel for road construction, comprising:

[0028] Mix fly ash, cement, sand, water and water reducer to get mortar;

[0029] forming said mortar into blocks;

[0030] The blocks are cured and crushed to obtain artificial crushed stones for road construction.

[0031] In the present invention, the fly ash is preferably high-calcium fly ash produced by a circulating fluidized bed coal-fired power generation enterprise, and the fineness of the high-calcium fly ash is preferably ≤30%; The mass fraction of free calcium oxide (f-CaO) in the ash is preferably 0.5-10%, more preferably 1-8%, most preferably 3-6%.

[0032] In the present invention, the fly ash preferably also includes before using:

[0033] The fly ash is carried out pre-curing, and the method for the pre-curing preferably includes:

[0034] Place the fly ash after spraying it with water;

[0035] The temperature for placing is 20-60°C;

[0036] The ...

Embodiment 1

[0054] The high-calcium fly ash with a fineness of 10% and a mass fraction of f-CaO of 5% is selected as a raw material;

[0055] Remove impurities from the high-calcium fly ash, spray water on the surface, and maintain at room temperature (about 25°C) and 60% RH for 48 hours;

[0056] Put 100Kg of 42.5 grade ordinary Portland cement, 50Kg of standard sand, 200Kg of high-calcium fly ash after the above treatment, 40kg of water and 1.2kg of polycarboxylate superplasticizer into a mortar mixer and stir evenly to obtain mortar;

[0057] The mortar is made into a mortar block with a size of 300mm*120mm*100mm by a block forming machine, the vibration pressure during the preparation process is 0.5MPa, the amplitude is 5±1mm, the frequency is 50Hz, and the molding time is 30s;

[0058] After placing the mortar block in the natural environment for 28 days, adopt the GB / T17671-1999 "Cement Mortar Strength Test" method to detect the compressive strength of the cured mortar block obtaine...

Embodiment 2

[0061] The fineness is 10%, and the high-calcium fly ash with f-CaO mass fraction of 8% is selected as raw material;

[0062] Remove impurities from the high-calcium fly ash, spray water on the surface, and place it in an environment of about 40°C and 90% RH for 48 hours of maintenance;

[0063] Put 100Kg of 42.5 grade ordinary Portland cement, 50Kg of standard sand, 200Kg of high-calcium fly ash after the above treatment, 40kg of water and 1.2kg of polycarboxylate superplasticizer into a mortar mixer and stir evenly to obtain mortar;

[0064] The mortar is made into a mortar block with a size of 300mm*120mm*100mm by a block forming machine, the vibration pressure during the preparation process is 0.5MPa, the amplitude is 5±1mm, the frequency is 50Hz, and the molding time is 30s;

[0065] After the mortar block is placed in the natural environment for curing for 28 days, the cured mortar block is crushed by a jaw crusher to obtain artificial gravel with a particle size of 5-35...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com