Carbon dot and hydrotalcite-based pressed color-changing light-emitting sensor film and preparation method thereof

A technology for suppressing discoloration and hydrotalcite, applied in the direction of hydrotalcite, discoloration fluorescent materials, chemical instruments and methods, etc., can solve the problems of molecular structure destruction, fluorescence quenching, etc., achieve good sensitivity, improve sensitivity, and reduce non-radiative transitions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

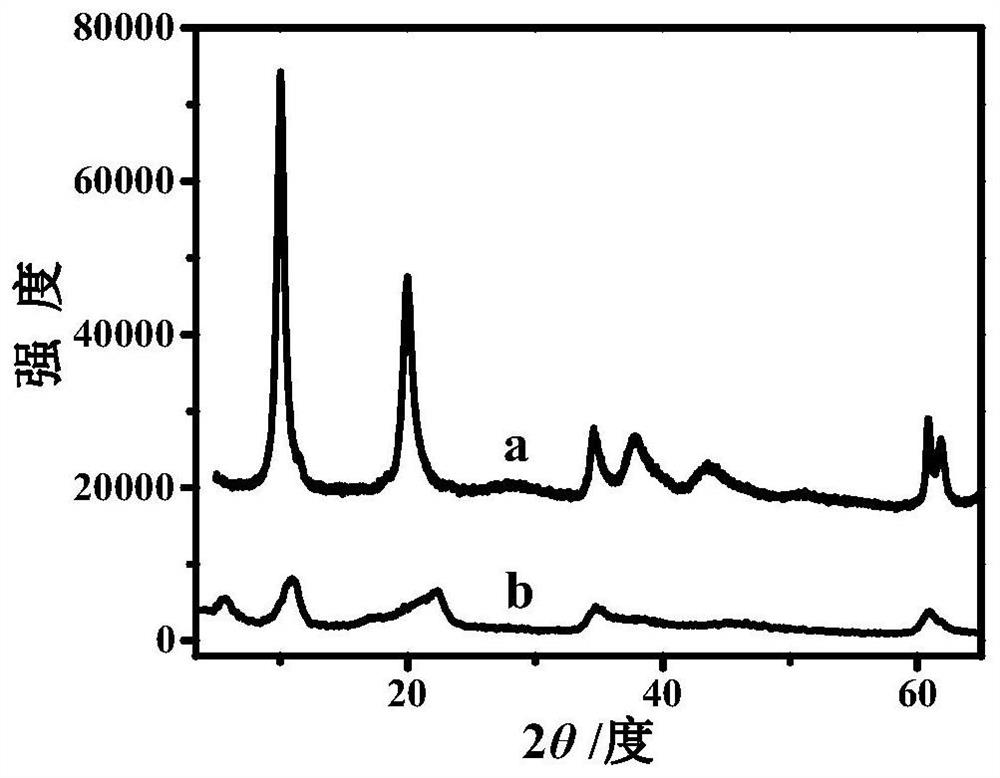

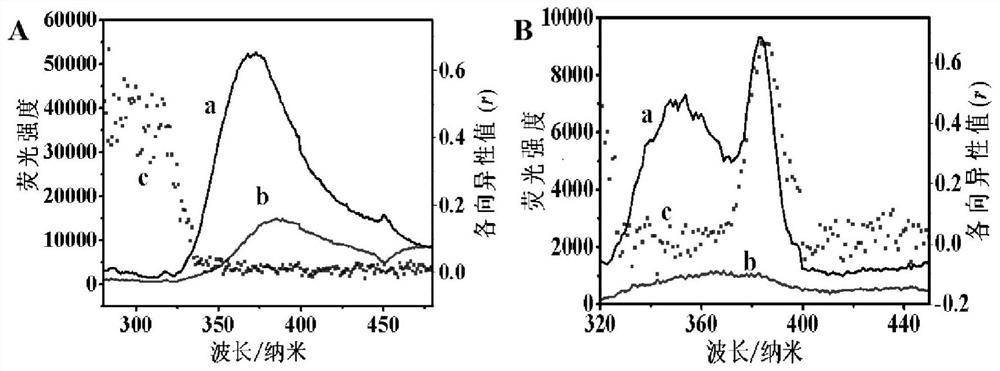

[0021] 1) Preparation of magnesium aluminum nitrate hydrotalcite by hydrothermal method: weigh 11.53g Mg(NO 3 ) 2 ·6H 2 O and 5.63g Al(NO 3 ) 3 9H 2 O (the molar ratio is 3:1) is dissolved in 90mL of water and poured into the three-necked flask; the NaOH solution with a concentration of 2M is slowly added dropwise to the three-necked flask, and the titration is completed after maintaining the pH=8.5; the solution in the three-necked flask is poured into In a high-pressure reaction kettle, the temperature is 100°C, and the time is 18h; after the reaction kettle is cooled to room temperature, the jelly is centrifuged and the precipitate is washed with water 4 times; the jelly is poured into a watch glass, and placed in a 50°C vacuum drying Box, dried into powder and taken out for use.

[0022] 2) Synthesis of intercalated hydrotalcite: Weigh the sample (0.012mol of 3-aminobenzenesulfonic acid) and dissolve it in 100mL of water, pour it into a three-necked flask; weigh 1.0g ...

Embodiment 2

[0027] 1) Magnesium aluminum nitrate hydrotalcite was prepared by hydrothermal method: 7.68g Mg(NO 3 ) 2 ·6H 2 O and 5.63g Al(NO 3 ) 3 9H 2 O (the molar ratio is 2:1) is dissolved in 100mL water and poured into the three-necked flask; the concentration is slowly added dropwise to the three-necked flask with a concentration of 2M NaOH solution, and the titration is completed after maintaining the pH=8.3; the solution in the three-necked flask is poured into In a high-pressure reaction kettle, the temperature is 110°C, and the time is 16h; after the reaction kettle is cooled to room temperature, the jelly is centrifuged and the precipitate is washed with water 4 times; the jelly is poured into a watch glass, and placed in a 60°C vacuum drying Box, dried into powder and taken out for use.

[0028] 2) Synthesis of intercalated hydrotalcite: weigh the sample (0.018mol of 3-aminobenzenesulfonic acid) and dissolve it in 110mL of water, pour it into a three-necked flask; weigh 1....

Embodiment 3

[0032] 1) Zinc-aluminum nitrate hydrotalcite was prepared by hydrothermal method: weigh 13.40g Zn(NO 3 ) 2 ·6H 2 O and 5.63g Al(NO 3 ) 3 9H 2 O (3:1 molar ratio) was dissolved in 150 mL of water and poured into a three-necked flask. Slowly add NaOH solution with a concentration of 2M to the three-necked flask, maintain the pH=6.5, and then end the titration. After the reactor was cooled to room temperature, the jelly was centrifuged and the precipitate was washed 6 times with water. Pour the jelly into a watch glass, place it in a vacuum oven at 70°C, dry it into powder, and take it out for use.

[0033] 2) Synthesis of intercalated hydrotalcite: Weigh the sample (0.020 mol of 3-aminobenzenesulfonic acid) and dissolve it in 130 mL of water, and pour it into a three-necked flask. Weigh 1.5g of zinc-aluminum nitrate hydrotalcite and place it in a three-necked flask, stir at 75°C for 75 hours and always pass nitrogen gas, wash the precipitate obtained after centrifugation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

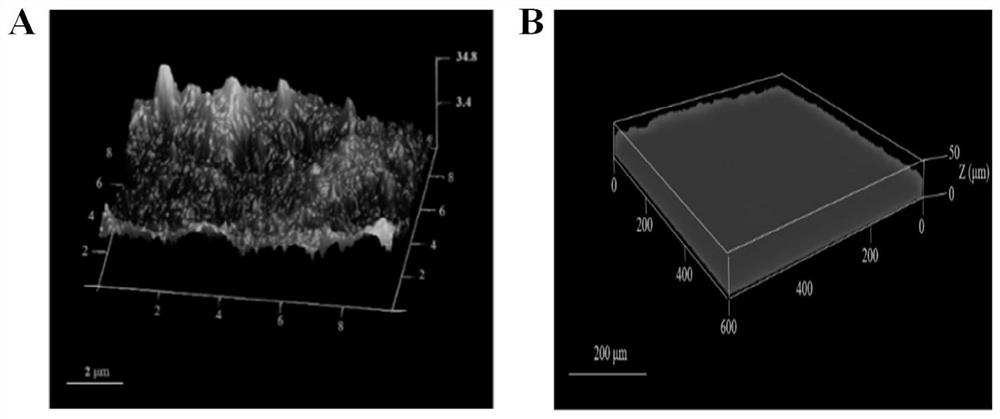

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com