Preparation method of inorganic filler for low-smoke halogen-free flame-retardant high-strength cable

A technology for inorganic fillers and cables, applied in circuits, electrical components, organic insulators, etc., can solve problems such as difficult cable processing and weakened mechanical properties, and achieve excellent comprehensive performance, improved tensile properties, and improved processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

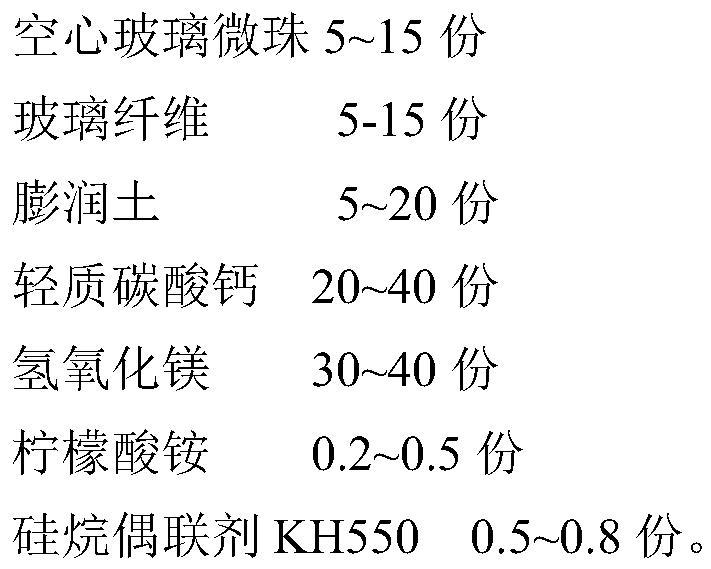

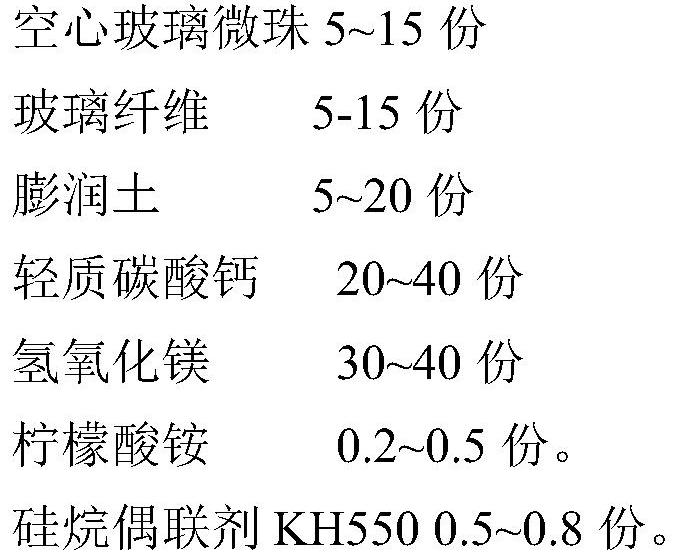

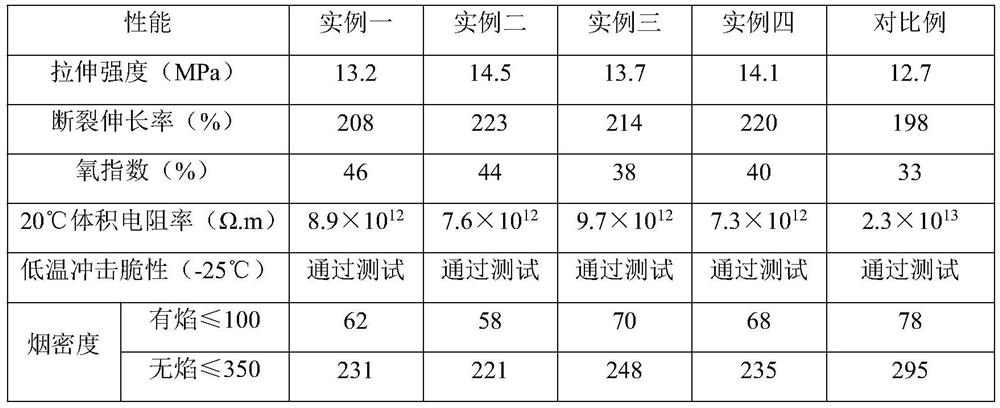

[0020] This example discloses a method for preparing an inorganic filler for low-smoke, halogen-free, flame-retardant, high-strength cables. The parts by weight of the corresponding components of the inorganic filler are: 15 parts of hollow glass microspheres, 5 parts of glass fiber, 5 parts of bentonite, 40 parts of light calcium carbonate, 34 parts of magnesium hydroxide, 0.5 parts of ammonium citrate, 0.5 parts of silane coupling agent KH5500. The concrete steps of preparing above-mentioned inorganic filler are as follows:

[0021] (1) Mix bentonite and distilled water at a mass ratio of 1:20, stir at 150 rpm for 10 minutes, and then ultrasonically disperse for 20 minutes.

[0022] (2) After step (1) is completed, continue to add magnesium hydroxide powder, control the rotating speed to be 200 rpm, and stir for 30 minutes.

[0023] (3) After step (2) is completed, continue to add light calcium carbonate and glass fiber, adjust the rotating speed to 300 rpm, and stir for 30...

Embodiment 2

[0029] This example discloses a method for preparing an inorganic filler for low-smoke, halogen-free, flame-retardant, high-strength cables. The parts by weight of the corresponding components of the inorganic filler are: 5 parts of hollow glass microspheres, 15 parts of glass fiber, 10 parts of bentonite, 30 parts of light calcium carbonate, 40 parts of magnesium hydroxide, 0.2 parts of ammonium citrate, 0.8 parts of silane coupling agent KH5500. The concrete steps of preparing above-mentioned inorganic filler are as follows:

[0030] (1) Mix bentonite and distilled water at a mass ratio of 1:30, stir at 150 rpm for 20 minutes, and then ultrasonically disperse for 30 minutes.

[0031] (2) After step (1) is completed, continue to add magnesium hydroxide powder, control the rotating speed to be 250 rpm, and stir for 20 minutes.

[0032] (3) After step (2) is completed, continue to add light calcium carbonate and glass fiber, adjust the rotating speed to 400 rpm, and stir for 3...

Embodiment 3

[0038] This example discloses a preparation method of an inorganic filler for low-smoke, halogen-free, flame-retardant, high-strength cables. 30 parts of light calcium carbonate, 30 parts of magnesium hydroxide, 0.3 parts of ammonium citrate, 0.7 parts of silane coupling agent KH5500. The concrete steps of preparing above-mentioned inorganic filler are as follows:

[0039] (1) Mix bentonite and distilled water at a mass ratio of 1:25, stir at 200 rpm for 15 minutes, and then ultrasonically disperse for 25 minutes.

[0040] (2) After step (1) is completed, continue to add magnesium hydroxide powder, control the rotating speed to be 240 rpm, and stir for 15 minutes.

[0041] (3) After step (2) is completed, continue to add light calcium carbonate and glass fiber, adjust the rotating speed to 350 rpm, and stir for 20 minutes.

[0042] (4) After step (3) is completed, slowly add a surface dispersant ammonium citrate aqueous solution with a concentration of 15%, control the speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com