Single-layer adhesive film, multi-layer co-extrusion adhesive film and photovoltaic cell module

A multi-layer co-extrusion, film technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problem of reduced light transmittance of photovoltaic modules, and achieve the effect of improving photoelectric conversion rate, utilization rate, and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

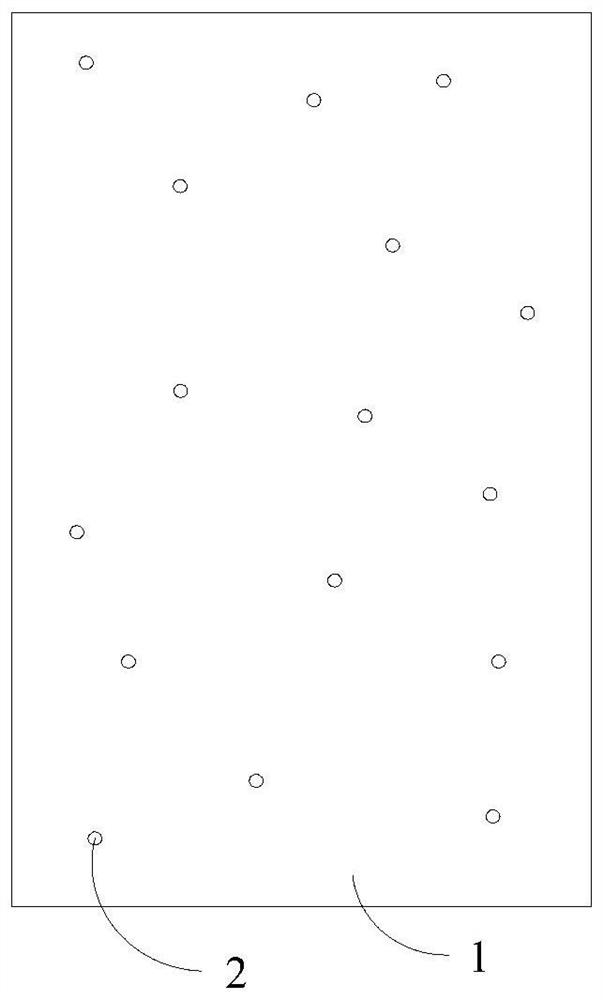

[0033] Such as figure 1 and figure 2 As shown, a single-layer adhesive film includes: a key functional layer 1 , in which a number of pores 2 are formed by physical or chemical foaming. Among them, the key functional layer 1 is made of electrical insulating resin, which can be but not limited to polyolefin, ethylene-vinyl acetate copolymer, polyvinyl butyral, ionomer, polyurethane, silica gel, epoxy resin, etc. One or more of resin and EPDM rubber. In this embodiment, transparent polyolefin is selected as the base material for the key functional layer 1 .

[0034] The chemical method is to add a foaming agent inside, and then foam to form pores 2 . The diameter of the pores 2 is 1-10 microns, and the thickness of the key functional layer 1 is 500 microns.

[0035] Wherein, the key functional layer 1 is cured by UV curing or heat curing. UV curing is UV curing. Thermal curing uses high temperature to cure the electrical insulating resin.

Embodiment 2

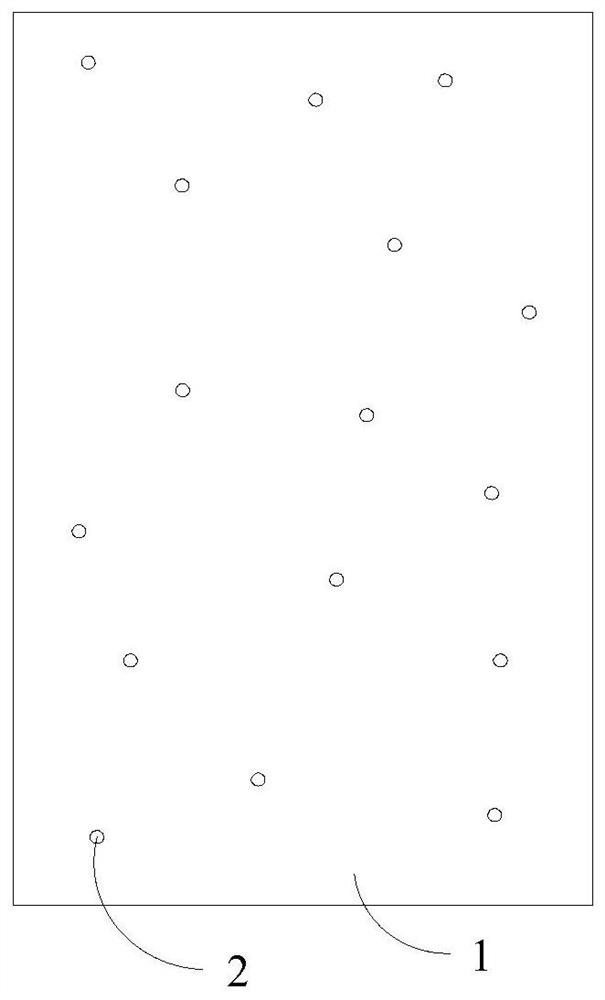

[0037] Such as image 3 and Figure 4 As shown, a multi-layer co-extruded adhesive film includes at least one layer of the above-mentioned single-layer adhesive film and at least one layer of conventional adhesive film 3; the conventional adhesive film 3 is made of transparent polyolefin material. The conventional adhesive film 3 is prepared by a film preparation method for photovoltaics.

Embodiment 3

[0039] A photovoltaic cell assembly, which is obtained by encapsulating the single-layer adhesive film obtained in Example 1 or the multi-layer co-extruded adhesive film obtained in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com