High-low-temperature-resistant low-infrared-emissivity coating and preparation method thereof

A technology with low infrared emission and high and low temperature resistance, applied in the direction of epoxy resin coating, coating, etc., can solve the problem that high temperature resistance performance is only applicable, and achieve the effect of good construction and excellent protection function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

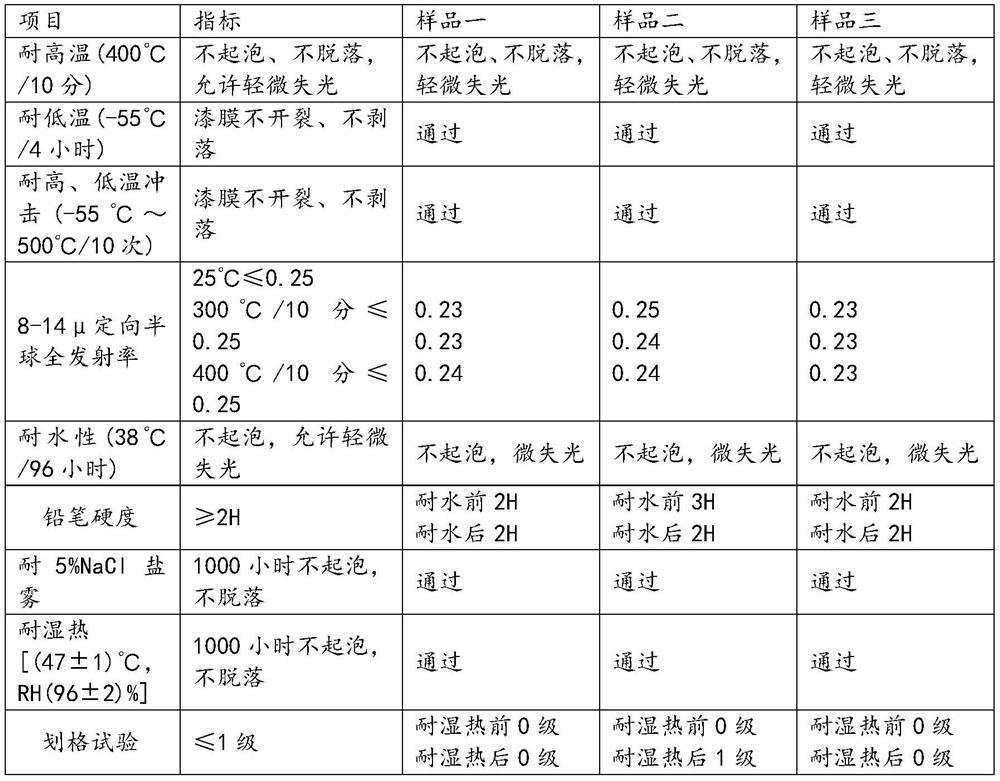

Examples

Embodiment 1

[0030] A coating with high and low temperature resistance and low infrared emissivity, prepared by the following method:

[0031] ① Preparation of special diluent:

[0032] Stir and mix butyl acetate, n-butanol, and propylene glycol methyl ether acetate according to a weight ratio of 60:25:10.

[0033] ② Preparation of coating component A:

[0034] ②-1. Accurately weigh 50kg of epoxy resin 618, add it to the dispersing equipment with a mixer, add 22kg of special diluent that has been prepared, start stirring at a medium speed of 600-800 rpm, and stir the resin liquid evenly. It takes about 8 minutes or so.

[0035] ②-2. Accurately weigh 3kg of dispersant (BYK161), 0.1kg of leveling agent (BYK310), and 2kg of adhesion promoter (6210), and add them to the dispersing equipment and stir evenly. It takes about 12 minutes.

[0036] ②-3. Reduce the stirring speed to 400 rpm, slowly add 46 kg of accurately weighed flake aluminum powder slurry (STAPA15), and stir for about 18 minute...

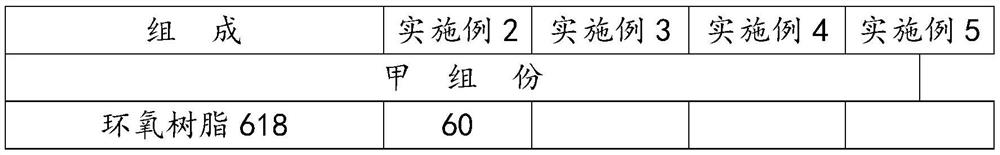

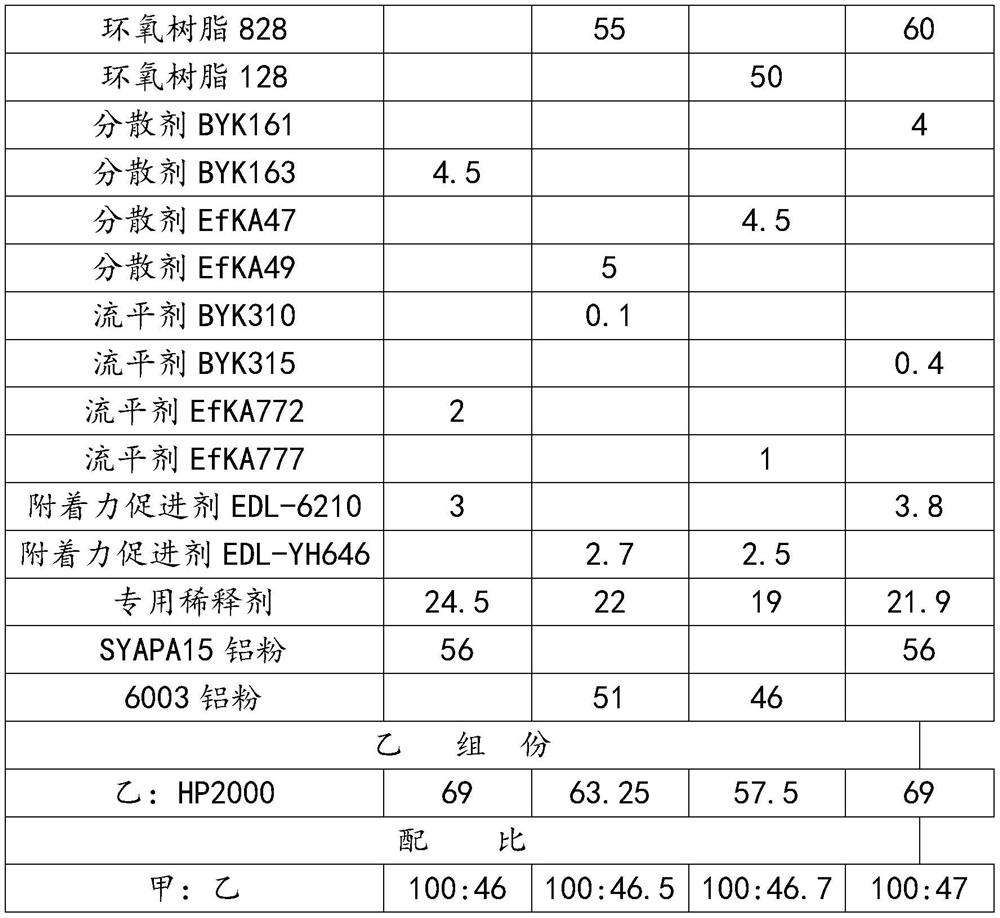

Embodiment 2~5

[0040] The formula is shown in Table 2 below, and the manufacturing method is the same as in Example 1.

[0041] Table 2

[0042]

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com