Comprehensive recycling method of waste lithium ion battery

A lithium-ion battery, waste technology, applied in the field of hydrometallurgy, can solve the problems of high logistics transportation cost, time cost, long process, etc., and achieve the effect of maximizing economic benefits and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

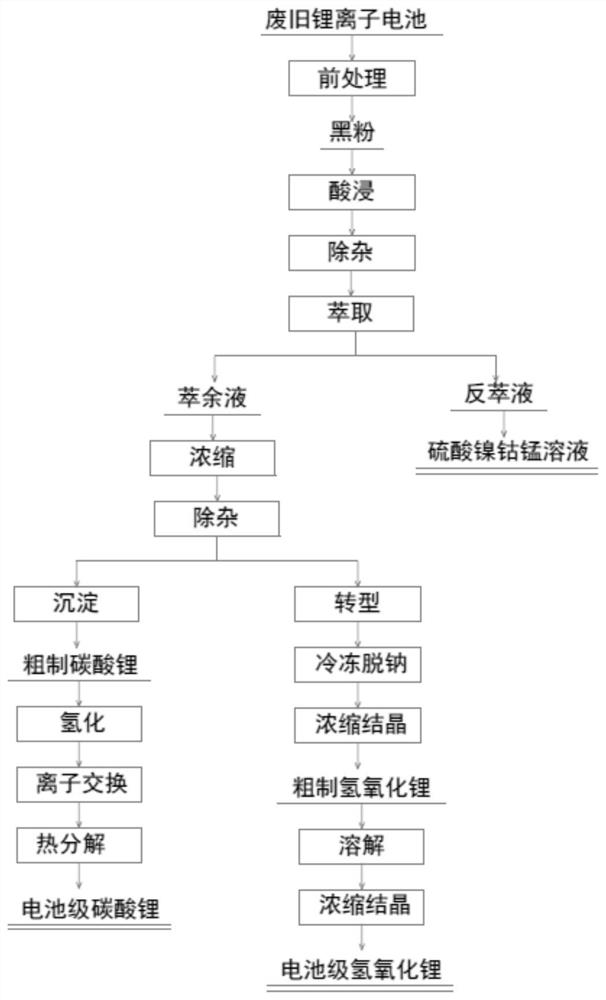

[0028] A method for comprehensive recycling of waste lithium-ion batteries, characterized in that the method comprises:

[0029] (1) Obtain black powder (weight is 50g) through discharge, heat treatment, crushing and sorting pretreatment of waste lithium ion battery:

[0030] Acid leaching: the mass ratio of nitric acid to black powder is 1:1, and the mass ratio of sodium metabisulfite to black powder is 0.5:1 for acid leaching. The reaction time is 4 hours and the reaction temperature is 80°C ;

[0031] Impurity removal: the oxidant used is air, the alkali used is magnesium oxide, the pH of the solution is adjusted to 2.5, the temperature is controlled to 25°C, and the reaction time is 4 hours;

[0032] Extraction: The extraction agent is P204, the ratio of oil phase to water is 1:1, and the stripping solution and raffinate are obtained after extraction, and the stripping solution is a mixed nickel-cobalt-manganese sulfate solution;

[0033] (2) Concentrate the raffinate ob...

Embodiment 2

[0036] Step (1) and step (2) are with embodiment 1, and wherein, in the pickling operation, acid adopts hydrochloric acid, and the ratio of addition and black powder is 1.3:1, and reducing agent is that the ratio of addition of sulfur dioxide and black powder is 1:1, the reaction time is 6 hours, the temperature is 60°C; in the impurity removal process, the oxidant is hydrogen peroxide, the alkali is calcium carbonate, the temperature is 45°C, the reaction time is 0.5 hours; the extraction agent is P507, and the oil-water ratio is 3 :1;

[0037] In step (3), the solution to be treated obtained in step (2) is transformed, frozen, concentrated and crystallized for the first time, dissolved, and concentrated and crystallized for the second time to obtain battery-grade lithium hydroxide; wherein, the transformation process: the added reagent is hydrogen Sodium oxide, the amount added is [OH - ]: [Li 2 O]=1:1(Li 2 O is in the solution to be treated);

[0038] Freezing process: ...

Embodiment 3

[0040] A method for comprehensive recycling of waste lithium-ion batteries, characterized in that the method comprises:

[0041] (1) Obtain black powder (weight is 70g) through discharge, heat treatment, crushing and sorting pretreatment of waste lithium ion battery:

[0042] Acid leaching: use a mixed acid of sulfuric acid and nitric acid, the mass ratio of the amount added to the black powder is 1.5:1, and the mass ratio of hydrogen peroxide as a reducing agent to the black powder is 1.5:1 for acid leaching, and the reaction time is 10 hours. The reaction temperature is 100°C;

[0043] Impurity removal: the oxidant used is sulfur dioxide + air, the alkali used is magnesium oxide, the pH of the solution is adjusted to 4, the temperature is controlled to 100°C, and the reaction time is 6 hours;

[0044] Extraction: The extraction agent is Cyanex272, the ratio of oil phase to water is 8:1, and the stripping solution and raffinate are obtained after extraction, and the strippin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com