Metal monatomic catalyst as well as preparation method and application thereof

A catalyst and metal technology, which is applied to a metal single-atom catalyst and its preparation method and application field, can solve the problems of increased chromaticity of effluent, high cost, leakage of metal ions, etc., and achieves the effect of reducing the dosage and solving the leakage of metal ions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

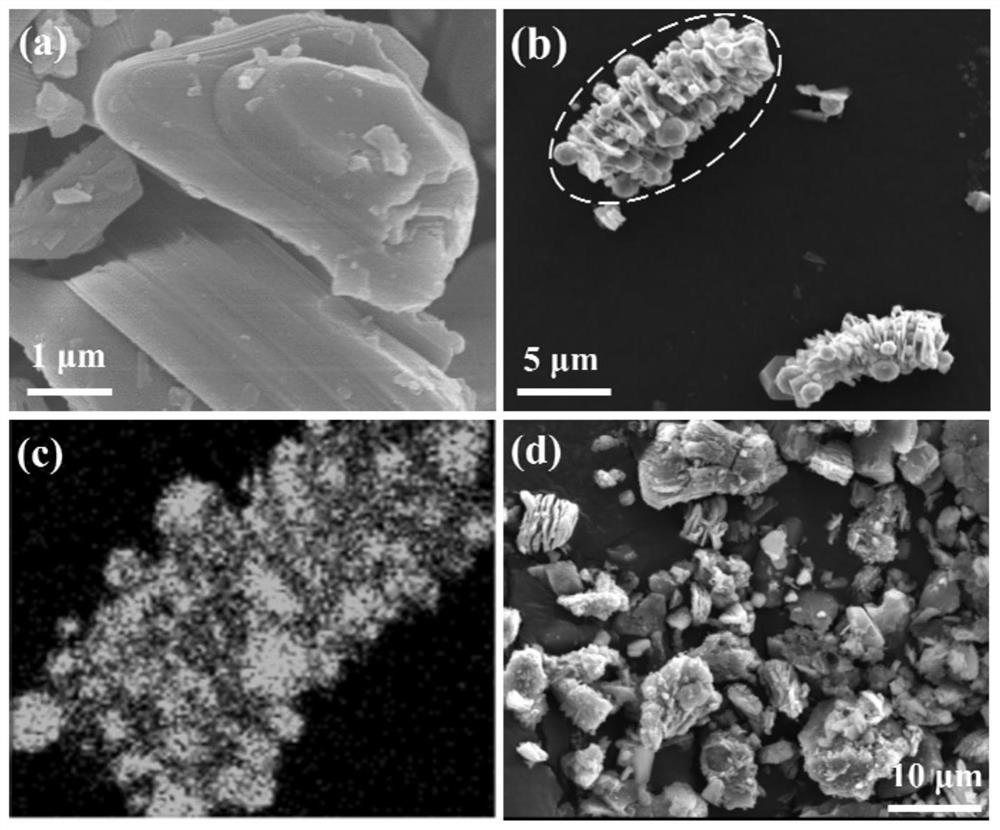

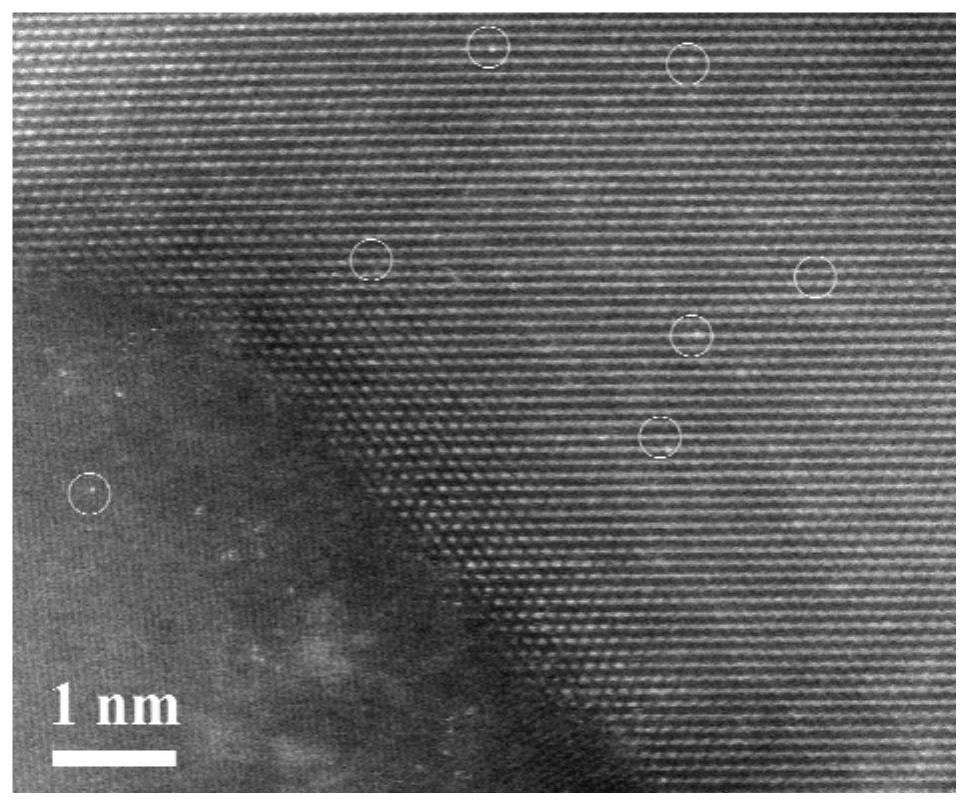

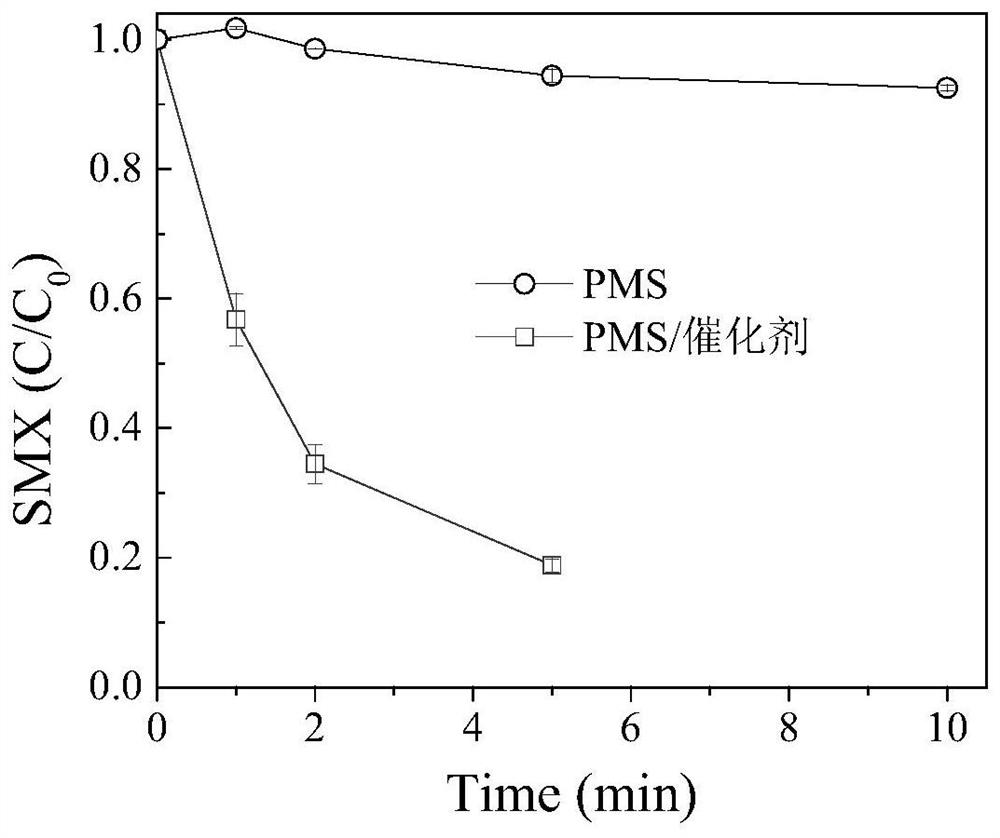

Embodiment 1

[0043] Under the atmosphere of high-purity Ar gas, Ti 3 AlC 2 Ceramic / CuCl 2 The mixed powder with a molar ratio of 1:10 was reacted at 900 °C for 48 h, washed with 3M HCl for 24 h, centrifuged, and freeze-dried to obtain the catalyst Cu@Ti loaded with single-atom Cu 3 C 2 (The loading of monoatomic Cu was determined to be 1.8% according to the EDS spectrum). Using a five-digit analytical balance, 20 mg of the catalyst loaded with single-atom Cu was weighed and added to a mixed solution (1000 mL) of 3 mM potassium persulfate (PMS) and 10 μM sulfamethoxazole (SMX) to initiate the reaction. During the reaction, the solution was stirred (500 rpm) using a magnetic stirrer to suspend the catalyst particles in the solution. Use a pipette gun to measure 1 mL of the solution at different time points, quickly filter the sample with a 0.22 μm filter membrane, add it to a liquid phase vial previously filled with 100 μL of methanol and ascorbic acid, and use high performance liquid ch...

Embodiment 2

[0045] In high purity N 2 Atmosphere, Ti 2 AlN ceramics / Co(NO 3 ) 2 The mixed powder with a molar ratio of 1:0.5 was reacted at 1000°C for 48 hours, using 5M HNO 3 The powder was washed for 10 h, centrifuged, and freeze-dried to obtain the catalyst Co@Ti loaded with single-atom Co 2 N (1.3% loading of monoatomic Co determined from EDS spectrum). Using a five-digit analytical balance, 20 mg of the catalyst loaded with monoatomic Co was weighed, and added to a mixed solution (1000 mL) of 2 mM PMS and 10 μM SMX to initiate the reaction. During the reaction, the solution was stirred (500 rpm) using a magnetic stirrer to suspend the catalyst particles in the solution. Use a pipette gun to measure 1 mL of the solution at different time points, quickly filter the sample with a 0.22 μm filter membrane, add it to a liquid phase vial previously filled with 100 μL of methanol and ascorbic acid, and use high performance liquid chromatography to determine the SMX concentration. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com