Preparation method and application of hierarchical pore molecular sieve

A molecular sieve and multi-stage pore technology, applied in the field of molecular sieves, can solve the problems of high price, inability to carry out large-scale application, and low yield of furan ether compounds, and achieve low cost, good application prospects, and high conversion activity of furan compounds Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

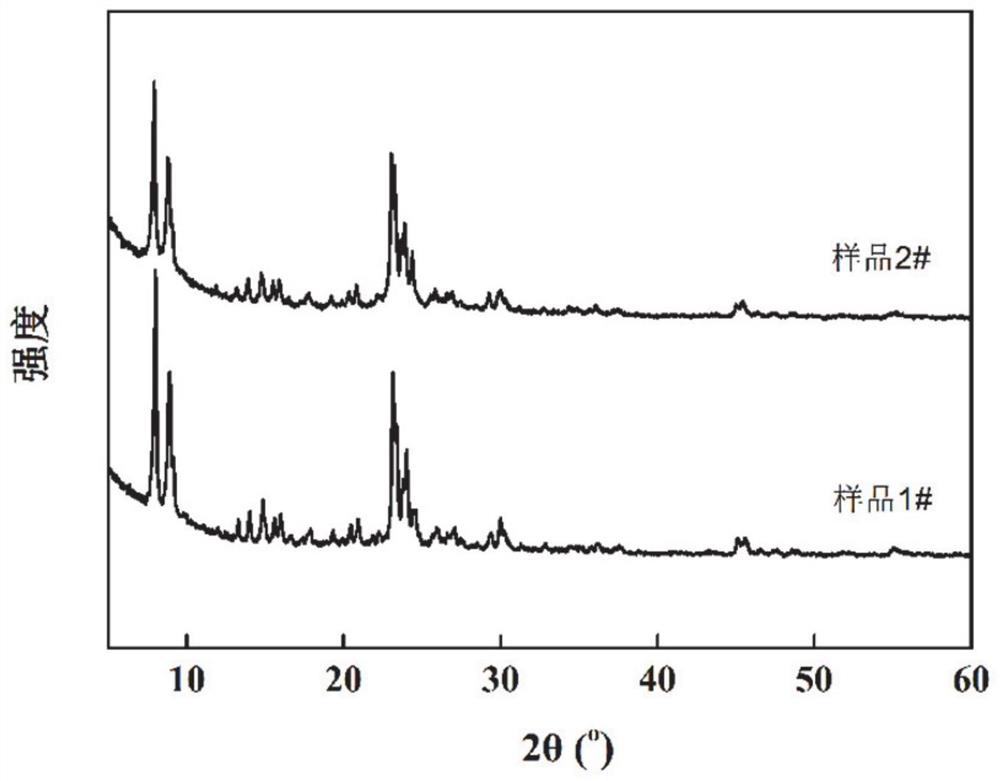

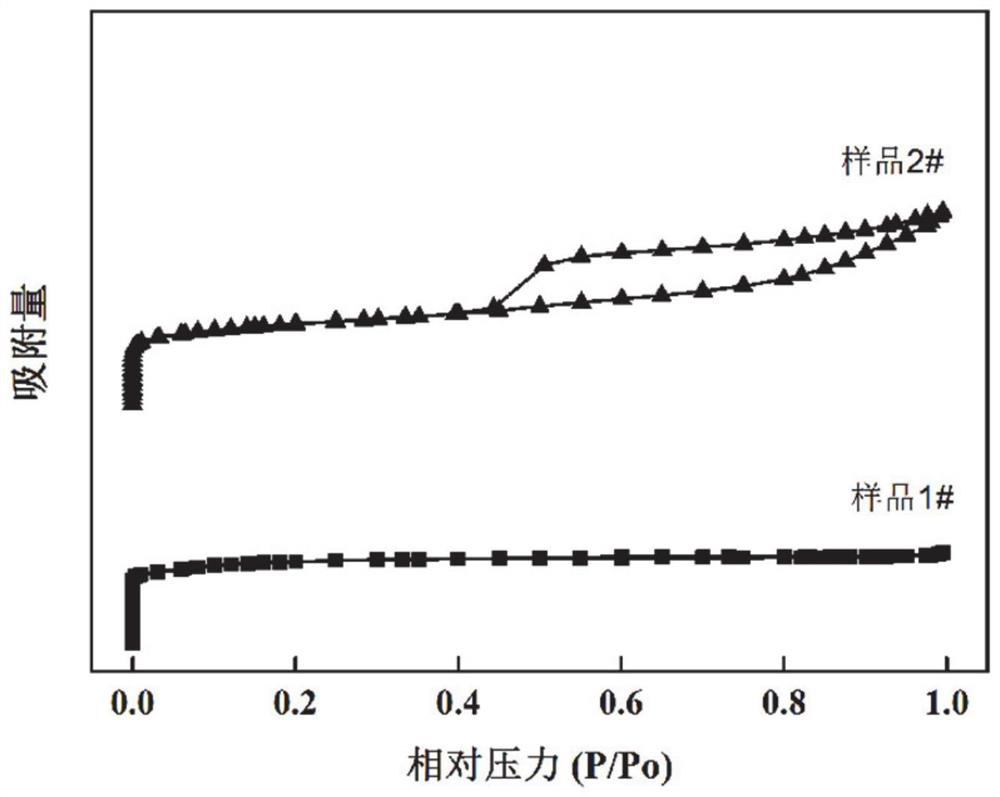

[0099] Example 1 Sample 1 # preparation

[0100] Mix 0.54g of ammonium chloride and 100mL of deionized water in a 250mL three-necked flask, heat and reflux to 80°C under stirring, then add 2g of microporous ZSM-5 molecular sieve (silicon-aluminum atomic ratio is 12), continue stirring for 1h and use Wash with deionized water, filter, and dry at 100°C for 2 hours; repeat the above ammonium ion exchange operation twice, and the obtained sample is calcined at 550°C for 7 hours to obtain an acidic microporous ZSM-5 molecular sieve, which is designated as sample 1 # .

Embodiment 2

[0101] Example 2 Sample 2 # preparation

[0102] Mix 2g of sodium hydroxide, 1.8g of cetyltrimethylammonium bromide and 100mL of deionized water in a 250mL three-neck flask, heat and reflux to 80°C under stirring, then add 2g of microporous ZSM-5 molecular sieve (silicon The molar ratio of aluminum atoms is 12.5), continued stirring for 24 hours, washed with deionized water, filtered, dried at 100°C for 2 hours, and calcined at 550°C for 7 hours to obtain ZSM-5 molecular sieve after alkali treatment.

[0103] Mix 0.54g of ammonium chloride and 100mL of deionized water in a 250mL three-necked flask, heat and reflux to 80°C under stirring, then add ZSM-5 molecular sieve after alkali treatment, continue stirring for 1 hour, wash with deionized water, and filter. Dry at 100° C. for 2 hours; repeat the ammonium ion exchange operation twice, and roast the obtained sample at 550° C. for 6 hours to obtain acidic ZSM-5 molecular sieve after alkali treatment.

[0104] Mix 0.18g of oxa...

Embodiment 3

[0105] Example 3 Sample 3 # preparation of

[0106] Mix 2g of sodium hydroxide, 1.8g of cetyltrimethylammonium bromide and 100mL of deionized water in a 250mL three-neck flask, heat and reflux to 80°C under stirring, then add 2g of microporous ZSM-5 molecular sieve (silicon The molar ratio of aluminum atoms is 25), continue to stir for 24h, wash with deionized water, filter, dry at 110°C for 2h, and roast at 550°C for 6h to obtain ZSM-5 molecular sieve after alkali treatment.

[0107] Mix 0.54g of ammonium chloride and 100mL of deionized water in a 250mL three-necked flask, heat and reflux to 80°C under stirring, then add ZSM-5 molecular sieve after alkali treatment, continue stirring for 1 hour, wash with deionized water, and filter. Dry at 100°C for 2h; repeat the above ammonium ion exchange operation twice, and the obtained sample is calcined at 550°C for 7h to obtain an acidic ZSM-5 molecular sieve after alkali treatment, which is designated as sample 3 # .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com