Preparation method and application of melanin/polylactic acid film

A technology of melanin and polylactic acid, which is applied in the field of preparation of melanin/polylactic acid film, can solve the problems of waste of resources, discarding, pollution, etc., and achieve the effects of avoiding environmental pollution, excellent toughness, and prolonging the shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a kind of preparation method of melanin / polylactic acid film, comprises the following steps:

[0041] (1) Extraction of melanin

[0042] S1, crushing: wash the apricot core and shell with tap water, dry at 70°C, after complete drying, use a pulverizer to crush the apricot core and shell into powder, pass through a 20-mesh sieve, and store in a dry environment spare;

[0043] S2, alkaline solution extraction: Weigh an appropriate amount of the apricot core-shell powder obtained in step S1, add 2mol / L NaOH solution according to the ratio of material to liquid 1:20, let stand for 3h, and centrifuge for 5min at the centrifuge speed of 8000r / min, Collect the supernatant, which is the crude extract of apricot core shell melanin;

[0044]S3, acid solution precipitation: add 6mol / L HCl solution to the crude extract of apricot core-shell melanin obtained in step S2 until the pH value is 2.20, centrifuge for 5min under the condition that the speed of the ...

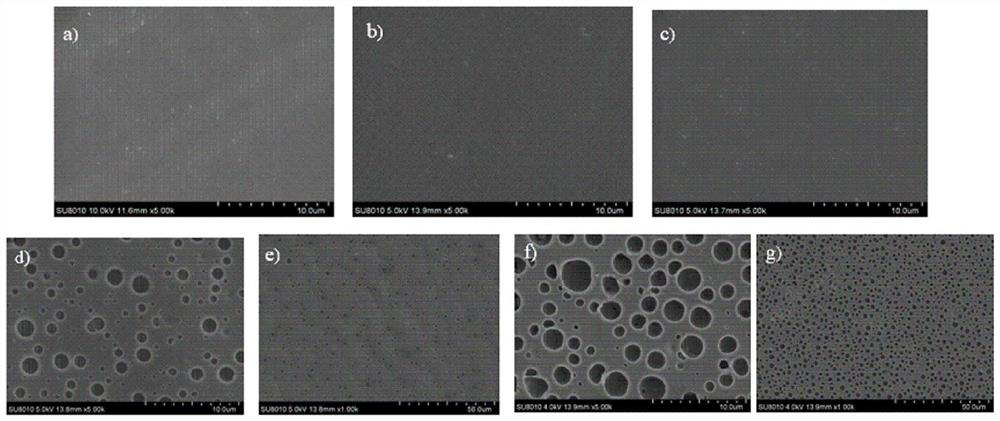

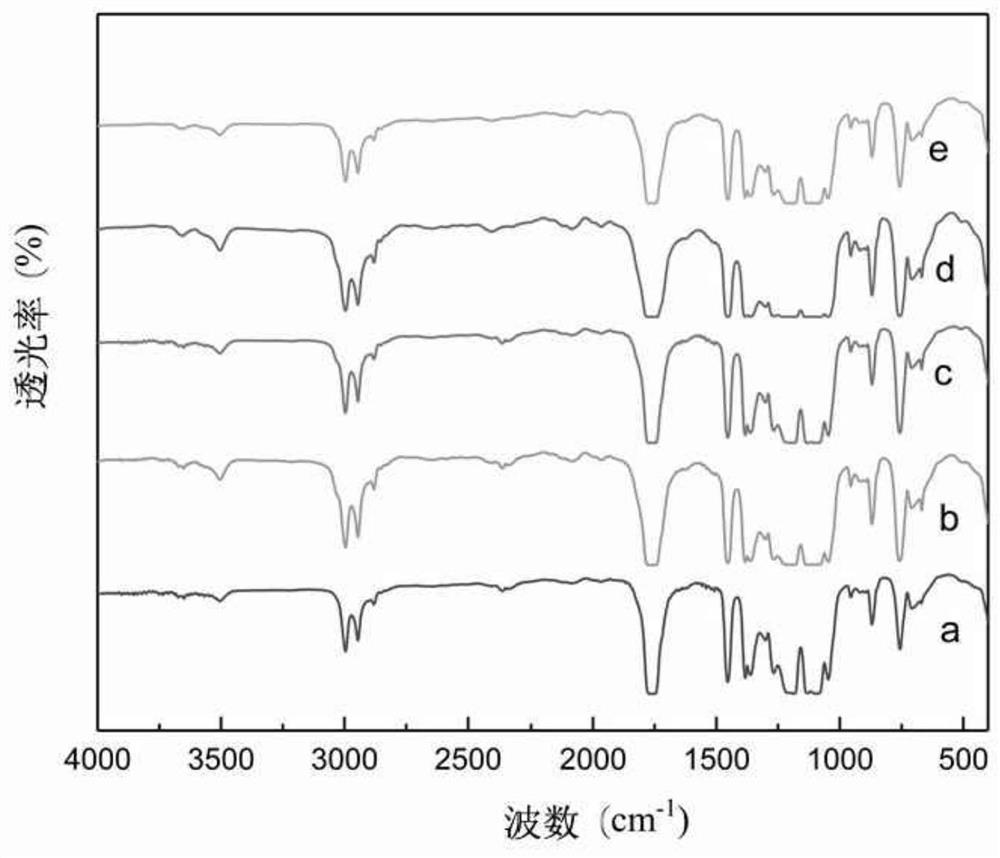

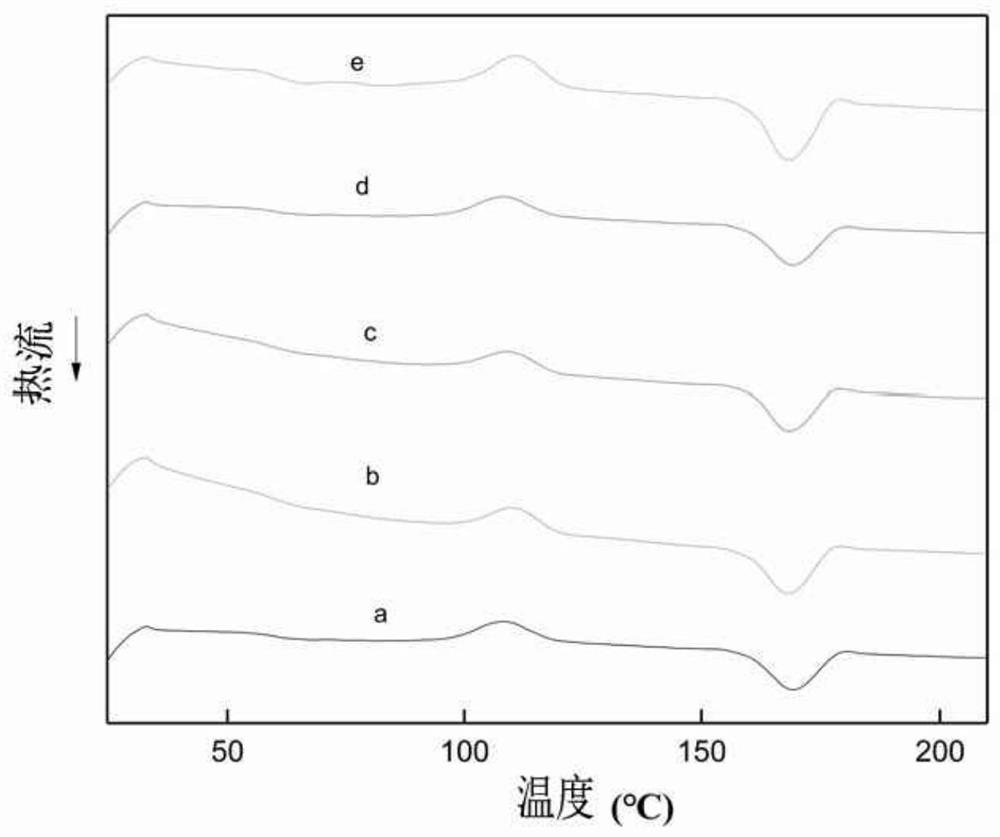

Embodiment 1

[0060] Weigh 2g of polylactic acid into a beaker, then add 30mL of chloroform solution, then put the beaker on a magnetic stirrer, and fully stir for 1h at 25°C, 5000r / min, after the solution is evenly stirred, put the beaker Place it on a magnetic stirrer and stir it fully for 7 hours at 25°C and 5000r / min. After the stirring is completed, extract with ultrasonic assistance for 10 minutes, then centrifuge for 5 minutes at a speed of 8000r / min. Finally, pour the solution into 20cm ╳ 20cm PTFE board, dry at room temperature in a ventilated place for 12 hours, and tear off to get PLA film.

Embodiment 2

[0062] Weigh 2g of polylactic acid into a beaker, then add 30mL of chloroform solution, then place the beaker on a magnetic stirrer, and fully stir for 1 hour at 25°C, 5000r / min. After the solution is evenly stirred, weigh it accurately Add 0.5 mg of melanin particles obtained in step (2) into a beaker, then place the beaker on a magnetic stirrer, and fully stir for 7 hours at 25°C and 5000r / min. / min, centrifuge for 5min, and finally, pour the solution into a 20cm╳20cm polytetrafluoroethylene plate, dry it at room temperature in a ventilated place for 12h, and tear it off to get melanin / PLA 0.025% film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transmittance | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com