Coated modified anhydrous lithium hydroxide and preparation method thereof

An anhydrous lithium hydroxide, modified technology, applied in the direction of lithium oxide; / hydroxide, electrochemical generator, electrical components, etc. Lithium-ion battery self-discharge and other problems, to improve the internal atmosphere of the kiln, reduce the influence of the kiln atmosphere and sintering, and improve the performance of low gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]A coating modified anhydrous lithium hydroxide of the present invention includes anhydrous lithium hydroxide and a coating layer coated on the surface of the anhydrous lithium hydroxide, and the coating layer material is ester organic matter (2, 2, 4 -Trimethyl-1,3-pentanediol monoisobutyrate).

[0039]The preparation method of the coated modified anhydrous lithium hydroxide of this embodiment includes the following steps:

[0040](1) Weigh acetone and 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate in a ratio of 74L:1L, and stir them evenly. The stirring speed is 60rpm and the stirring time is 3min. ;

[0041](2) Weigh 25 kg of lithium hydroxide monohydrate with a particle size D50 of 480 μm, and mix it with the mixed solvent obtained after step (1), the stirring speed is 70 rpm, and the stirring time is 5 min;

[0042](3) Put the monohydrate lithium hydroxide mixed solution obtained in step (2) into a sand mill, the speed of the sand mill is 420r / min, and the sanding time is 180min;

[004...

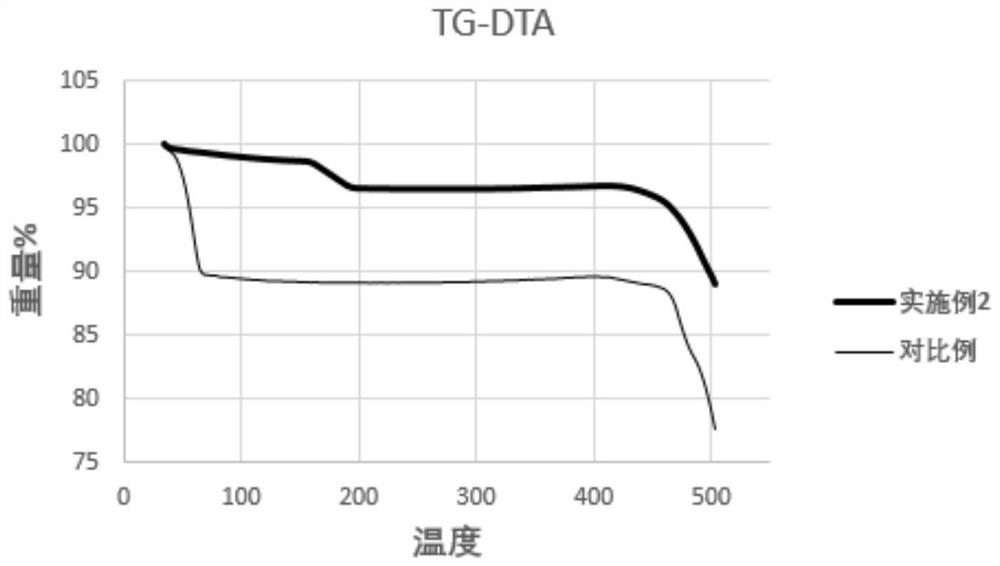

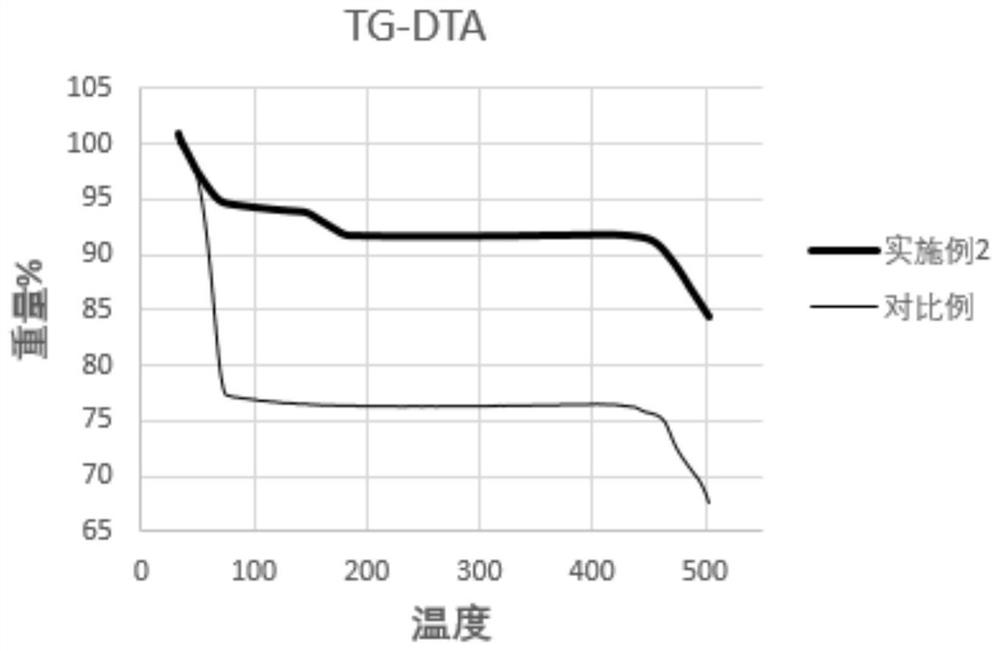

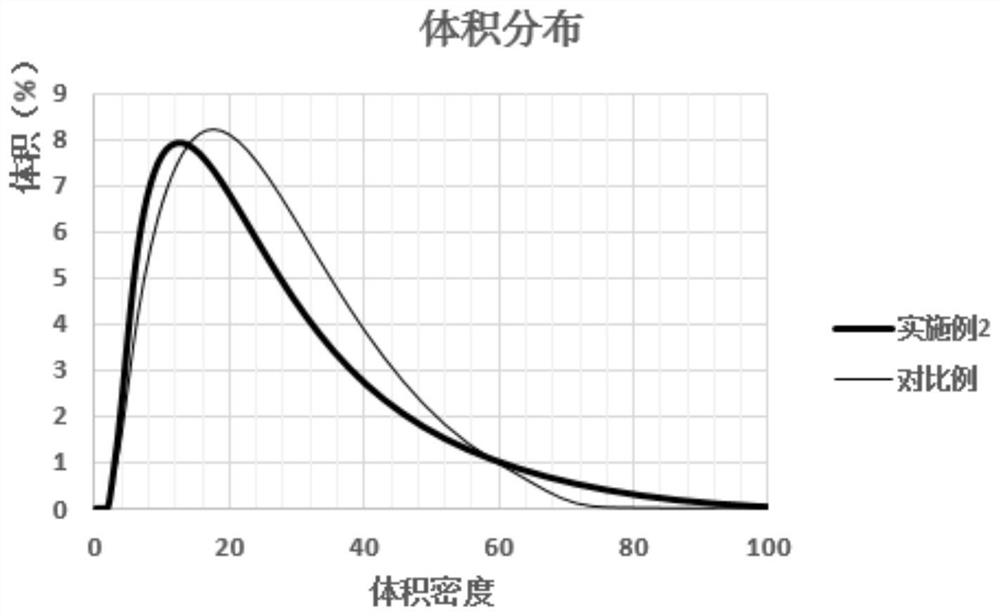

Embodiment 2

[0046]A coating modified anhydrous lithium hydroxide of the present invention includes anhydrous lithium hydroxide and a coating layer coated on the surface of the anhydrous lithium hydroxide, and the coating layer material is alkane organics (n-nonane).

[0047]The preparation method of the coated modified anhydrous lithium hydroxide of this embodiment includes the following steps:

[0048](1) Weigh acetone and n-nonane according to the ratio of 73.5L:1.5L, and stir them evenly, the stirring speed is 60rpm, and the stirring time is 3min;

[0049](2) Weigh 18.75kg of lithium hydroxide monohydrate with a particle size D50 of 480μm (the SEM image is asFigure 5Shown), and mix with the mixed solvent obtained after step (1) evenly, the stirring speed is 70rpm, and the stirring time is 5min;

[0050](3) Put the monohydrate lithium hydroxide mixed solution obtained in step (2) into a sand mill, the speed of the sand mill is 420r / min, and the sanding time is 180min;

[0051](4) Put the sand-milled lithium...

Embodiment 3

[0054]A coating modified anhydrous lithium hydroxide of the present invention includes anhydrous lithium hydroxide and a coating layer coated on the surface of the anhydrous lithium hydroxide. The coating layer material is a lipid organic matter (C12-14 fatty acid) .

[0055]The preparation method of the coated modified anhydrous lithium hydroxide of this embodiment includes the following steps:

[0056](1) Weigh n-hexane and C12-14 fatty acid according to the ratio of 73L:2L, and stir evenly, the stirring speed is 60rpm, and the stirring time is 3min;

[0057](2) Weigh 15 kg of lithium hydroxide monohydrate with a particle size D50 of 480 μm, and mix it evenly with the mixed solvent obtained after step (1), the stirring speed is 70 rpm, and the stirring time is 5 minutes;

[0058](3) Put the monohydrate lithium hydroxide mixed solution obtained in step (2) into a sand mill, the speed of the sand mill is 420r / min, and the sanding time is 180min;

[0059](4) Put the sand-milled lithium hydroxide mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com