A drag-reducing viscosity-reducing agent for oil well cement and its preparation method

An oil well cement and drag reducing agent technology, applied in the field of materials, can solve the problems of obvious viscosity increasing effect, strong acidity and high molecular weight, and achieve the effects of avoiding the side effects of viscosity increasing, reducing frictional resistance and reducing system viscosity.

Active Publication Date: 2022-06-03

TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, more and more AMPS polymers are used in oil well cement fluid loss reducers and high temperature retarders, and some functional materials such as toughening agents, anti-channeling agents, and self-healing agents are mostly polymer systems, but Due to the high molecular weight of the polymer and the obvious viscosification effect, it is easy to cause problems such as difficulty in ash in the system, high viscosity of the slurry, and difficulty in adjusting the rheological properties of the system, especially in high temperature, high density and seawater cement slurry systems.

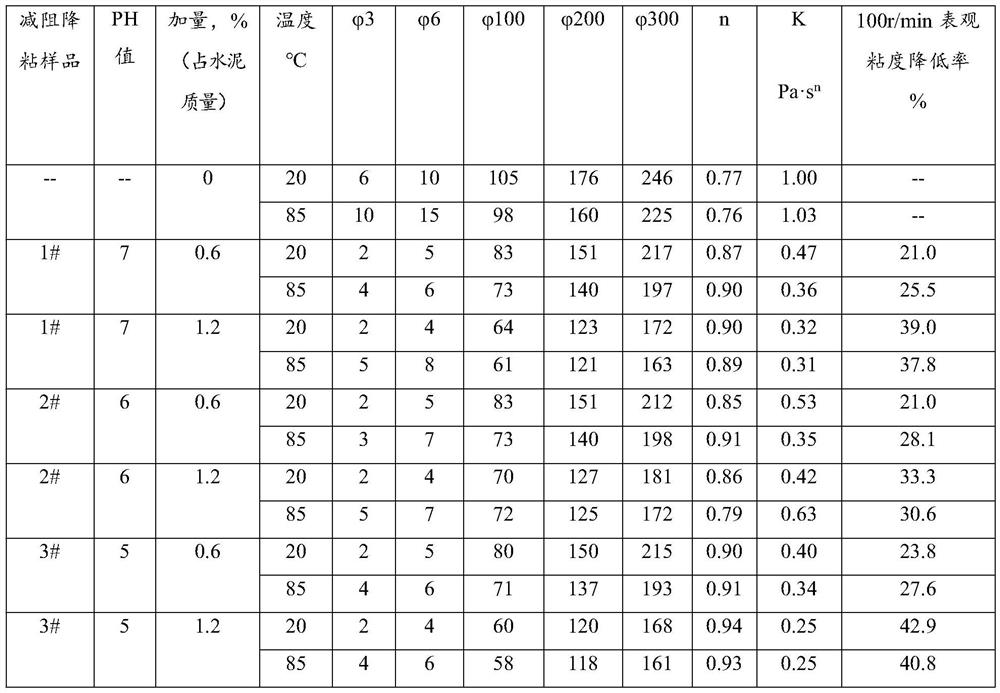

[0003] Adding drag reducer is considered to be the first choice to solve the above problems, but the current drag reducer often has the following problems: (1) The viscosity reduction effect is not obvious, and it is almost impossible to reduce the viscosity of the cement slurry system with AMPS polymer as the main agent , the effect of rheological improvement is small

(2) Strong acidity, obvious retarding effect, affecting the strength development of cement stone, and there are safety risks in transportation, storage and use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

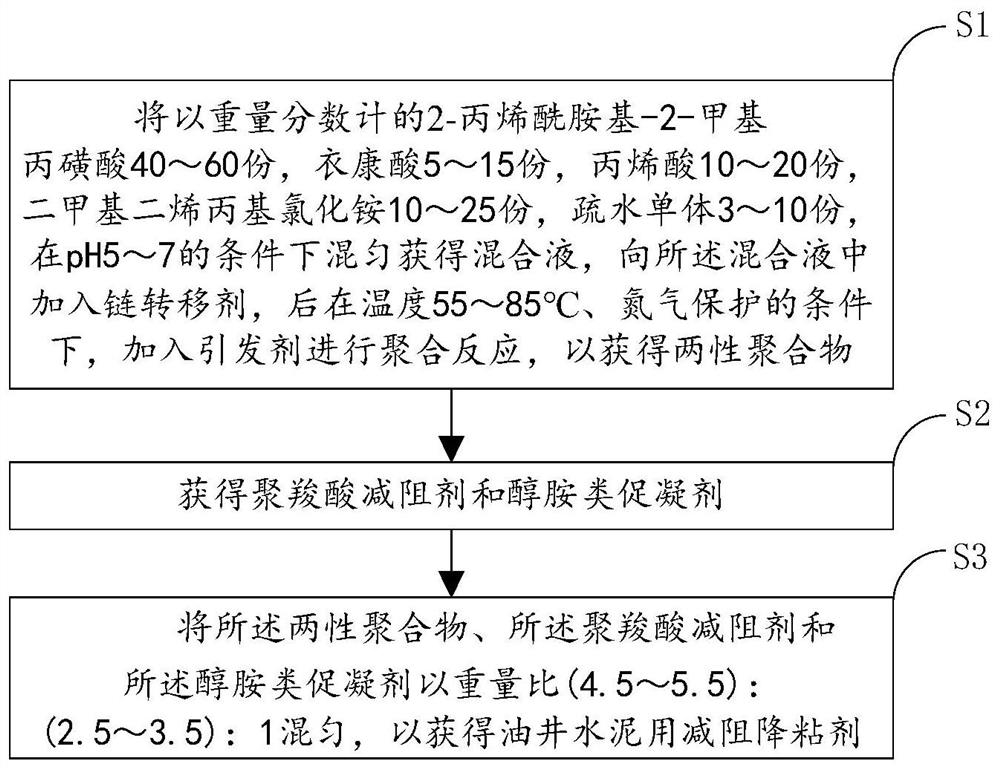

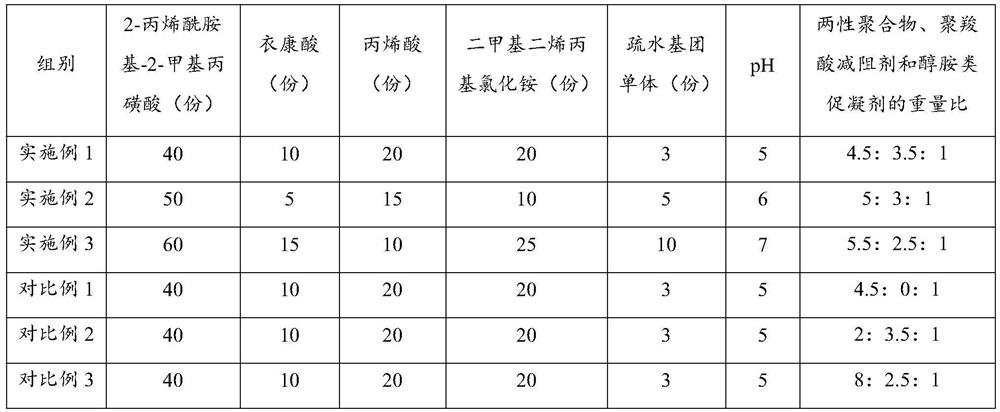

[0039] The amphoteric polymer, the polycarboxylic acid drag reducing agent and the alcoholamine coagulant are in a weight ratio (4.5 to 5.5):

[0041] The hydrophobic monomer includes one or both of butyl acrylate and cetyldimethylallyl ammonium chloride. Even

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a drag reducing and viscosity reducing agent for oil well cement and a preparation method thereof. 5-15 parts of acid, 10-20 parts of acrylic acid, 10-25 parts of dimethyl diallyl ammonium chloride, 3-10 parts of hydrophobic monomer, mix well under the condition of pH 5-7, add chain transfer agent, Finally, under the conditions of temperature 55-85°C and nitrogen protection, an initiator is added to carry out polymerization reaction to obtain an amphoteric polymer; a polycarboxylic acid drag reducer and an alcohol amine coagulant accelerator are obtained; the amphoteric polymer, polycarboxylate The acid drag reducer and the alcohol amine coagulant accelerator are mixed in a weight ratio of (4.5-5.5):(2.5-3.5):1 to obtain a drag-reducing and viscosity-reducing agent for oil well cement. The drag-reducing and viscosity-reducing agent of the invention is weakly acidic, can significantly reduce the viscosity of a cement slurry system with synthetic AMPS polymer as the main agent, and improve the rheology of the cement slurry.

Description

A kind of drag-reducing and viscosity-reducing agent for oil well cement and preparation method thereof technical field [0001] The present invention relates to the technical field of materials, in particular to a drag-reducing and viscosity-reducing agent for oil well cement and a preparation method thereof. Background technique With the gradual deepening of exploration and development, there are more and more complex environments, which puts forward higher requirements for cementing materials. beg. Synthetic polymer materials, especially AMPS-based polymer materials, have become the most popular polymers due to their high temperature resistance, salt resistance, and diversified functions. The leading material of admixture for well cement. At present, more and more fluid loss reducers and high temperature resistant setting retarders are used for oil well cement. AMPS polymers, some functional materials such as tougheners, anti-channeling agents, and self-healing agen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08F220/58C08F222/02C08F220/06C08F226/02C08F220/18C09K8/467

CPCC08F220/585C09K8/467C09K2208/28C08F222/02C08F220/06C08F226/02C08F220/1804Y02W30/91

Inventor 卢海川安少辉高继超郑会锴冯望生王海平李宗要谢承斌

Owner TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com