Coffee grounds modified biodegradable composite material and preparation method and application thereof

A biodegradable and composite material technology is applied in the field of preparation of coffee grounds modified biodegradable composite materials, which can solve the problems of brittleness and high market price of materials, will not easily degrade, reduce the price of raw materials, etc. The effect of increasing the degradation rate and reducing the cost of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

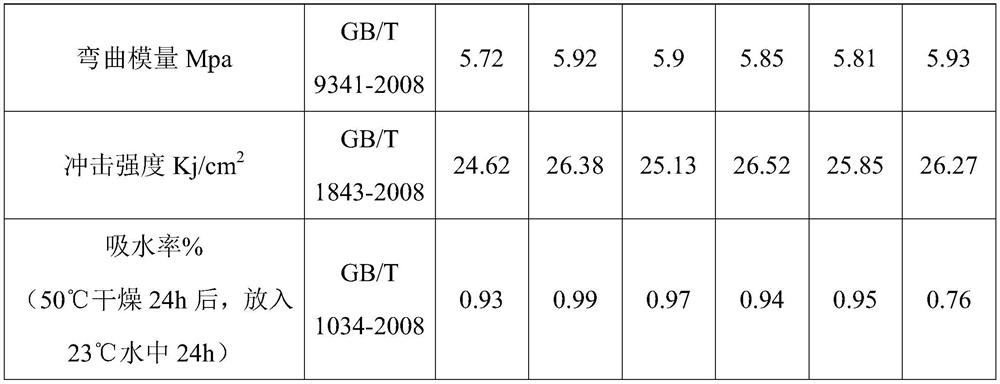

Examples

preparation example Construction

[0033] The preparation method of the coffee grounds modified biodegradable composite material comprises the following steps:

[0034] (1) Grinding the coffee grounds into nanoscale coffee grounds with nanoscale fineness in a grinder to obtain nanoscale coffee grounds;

[0035] (2) adding nanoscale coffee grounds, polylactic acid, biodegradable copolyester, compatibilizer, plasticizer and tackifier into a mixer by weighing the above-mentioned raw material ratio and uniformly mixing to obtain a compound;

[0036] (3) Add the homogeneously mixed mixture into a twin-screw extruder, and extrude the mixture at a preset extrusion temperature to obtain a biodegradable composite material modified with coffee grounds.

[0037] Polylactic acid (PLA) is a natural biodegradable plastic that has been industrially produced. Polylactic acid has excellent optical properties and high modulus, but its elongation at break, tear strength and breaking strength are all low. In order to overcome th...

Embodiment 1

[0046] A biodegradable composite material modified by coffee grounds, specifically, it is weighed and then mixed by the following raw materials according to the ratio of the above weight percentage, and the ratio is the weight ratio: polylactic acid 5%, poly (butyl adipate Glycol ester - butylene terephthalate copolymer) 70%, glycidyl methacrylate 5%, acetyl tri-n-butyl citrate 5%, maleic anhydride 5%, nano coffee grounds 10% .

[0047] The preparation method of the coffee grounds modified biodegradable composite material comprises the following steps:

[0048] (1) dehydrating, dehumidifying, and drying the waste residue produced after the coffee beans are ground and boiled in the dryer; grinding the dried coffee grounds into nano-scale coffee grounds with nano-scale fineness in the grinder;

[0049] (2) Nanoscale coffee grounds, polylactic acid, poly(butylene adipate-butylene terephthalate copolymer), glycidyl methacrylate, acetyl tri-n-butyl citrate, Maleic anhydride is we...

Embodiment 2

[0053] A biodegradable composite material modified by coffee grounds, specifically, it is made by weighing and then mixing the following raw materials according to the ratio of the above weight percentage, and the ratio is weight ratio: polylactic acid 12%, polybutylene succinate Alcohol ester 20%, ethanolamine 8%, epoxidized soybean oil 5%, maleic anhydride 5%, nano coffee grounds 50%.

[0054] The preparation method of the coffee grounds modified biodegradable composite material comprises the following steps:

[0055] (1) dehydrating, dehumidifying, and drying the waste residue produced after the coffee beans are ground and boiled in the dryer; grinding the dried coffee grounds into nano-scale coffee grounds with nano-scale fineness in the grinder;

[0056] (2) Weigh nanoscale coffee grounds, polylactic acid, polybutylene succinate, ethanolamine, epoxidized soybean oil, and maleic anhydride according to the above percentage by weight, and then add them to a high-speed mixer ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap