A lithium ion battery

A lithium-ion battery and lithium salt technology, applied in the field of electrochemistry, can solve the problems of unstable ternary material structure, poor battery high-voltage resistance performance, thermal runaway, etc., to suppress excessive increase in impedance or excessive concentration polarization. Large, low physical resistance increase rate, good effect of high temperature storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of positive electrode sheet:

[0042] The positive electrode active material LiNi 0.8 Co 0.1 Mn 0.1 O 2 , conductive carbon black SP and binder PVDF are dispersed in the solvent NMP for uniform mixing to obtain positive electrode slurry; the positive electrode slurry is uniformly coated on the positive current collector aluminum foil, and the coating weight of the positive electrode slurry is 0.309g / 1540.25 mm 2 (Based on the weight without solvent), after drying, cold pressing, slitting and cutting, a positive electrode sheet is obtained, wherein the mass ratio of the positive electrode active material, conductive carbon black and binder PVDF is 96:2 :2.

[0043] Preparation of negative pole piece:

[0044] The negative electrode active material natural graphite, conductive carbon black SP, thickener CMC and binder SBR are dispersed in solvent deionized water according to the mass ratio of 96:1:1:2 and mixed evenly to obtain negative electrode slurry;...

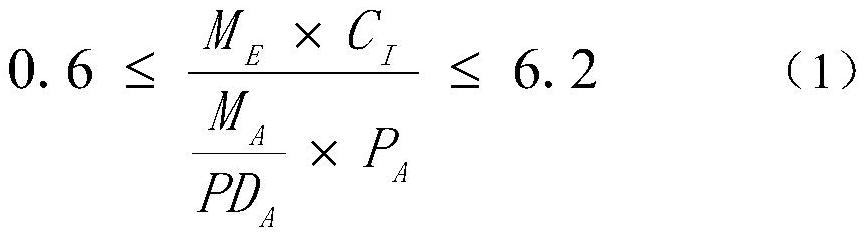

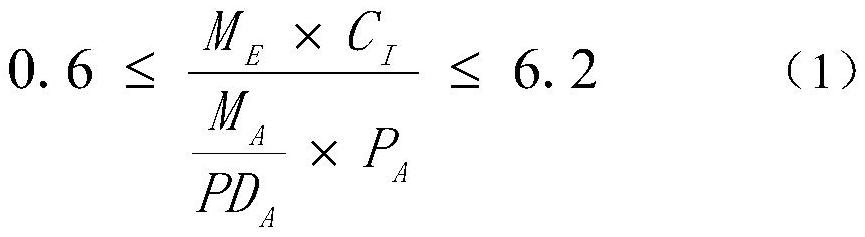

Embodiment 2-10 and comparative example 1-3

[0052] The preparation methods of positive pole piece, negative pole piece, electrolyte and lithium ion battery in Examples 2-10 and Comparative Examples 1-3 are basically the same as those in Example 1, except that the coating weight of the negative electrode slurry and the average particle size of the negative electrode active material are changed. Diameter, manufacturing parameters such as cold pressing pressure, etc., adjust the total mass M of negative active substances A , compaction density PD A and the pole piece porosity P A , the formulations and physical parameters of each embodiment and comparative example are shown in Table 1.

[0053] Table 1

[0054]

[0055]

[0056] testing method:

[0057] (1) Cyclic performance test of lithium ion secondary battery:

[0058] At 45°C, the fresh lithium-ion secondary batteries prepared in the examples and comparative examples were put on hold for 5 minutes, charged to 4.2V with a constant current at a rate of 1C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com