Pet beef powder yoghourt and processing method thereof

A processing method and technology of beef meal, applied in the direction of animal feed, animal feed, dairy products, etc., can solve the problems that pets do not like to drink, single function, and difficult to lick, and achieve good palatability, rich nutrition, and easy licking. the effect of eating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Pet beef yogurt formula composition: 85-95 parts of lactose-free milk, 1-2 parts of glucose, 0.5-1 powder of bovine collagen powder (mesh size greater than 80 mesh), 3-5 parts of beef powder (mesh size greater than 80 mesh) and Strains (one or more of Streptococcus thermophilus, Lactobacillus bulgaricus, Lactobacillus rhamnosus, Lactobacillus paracasei, Lactobacillus plantarum) 0.001-0.002 parts.

[0036] (1) According to the ratio of 11 to 13 parts of lactose-free milk powder + 87 to 89 parts of warm water at 50°C, the lactose-free milk powder is reduced to lactose-free milk, hydrated and cooled;

[0037] (2) Fully dry-mix the beef powder, bovine collagen powder and glucose in the formula quantity, then pour into the mixing tank, fully mix with lactose-free milk, and constant volume;

[0038] (3) Heating, homogenization, pasteurization, cooling: homogenization pressure 180±20bar, sterilization temperature 95℃ for 300s, cooling to 37℃;

[0039] (4) Inoculation, ferment...

Embodiment 2

[0042] Pet beef yogurt formula composition: 85-95 parts of lactose-free milk, 1-2 parts of glucose, 0.5-1 powder of bovine collagen powder (mesh size greater than 80 mesh), 3-5 parts of beef powder (mesh size greater than 80 mesh) and Bacterial species 0.001-0.002 parts.

[0043] (1) According to the ratio of 11 to 13 parts of lactose-free milk powder + 87 to 89 parts of warm water at 50°C, the lactose-free milk powder is reduced to lactose-free milk, hydrated and cooled;

[0044] (2) Fully dry-mix the beef powder, bovine collagen powder and glucose in the formula quantity, then pour into the mixing tank, fully mix with lactose-free milk, and constant volume;

[0045] (3) Heating, homogenization, pasteurization, cooling: homogenization pressure 180±20bar, sterilization temperature 95℃ for 300s, cooling to 37℃;

[0046] (4) Inoculation, fermentation, terminal acidity 50-60°T;

[0047] (5) Stirring, cooling and filling;

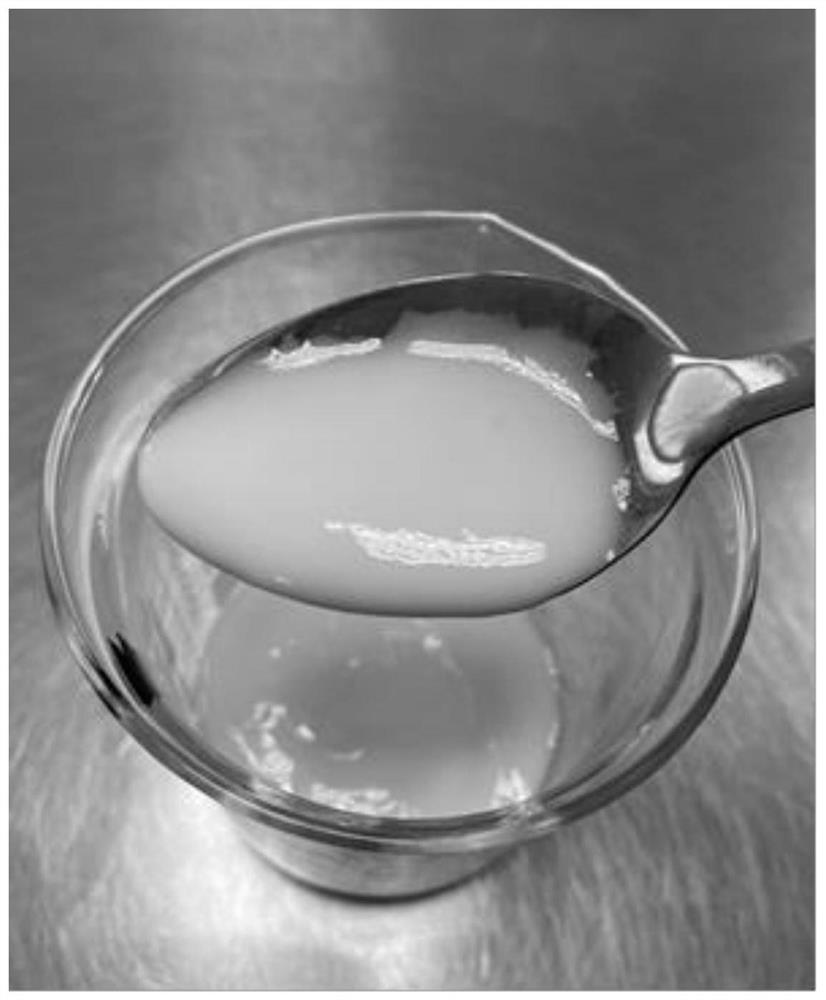

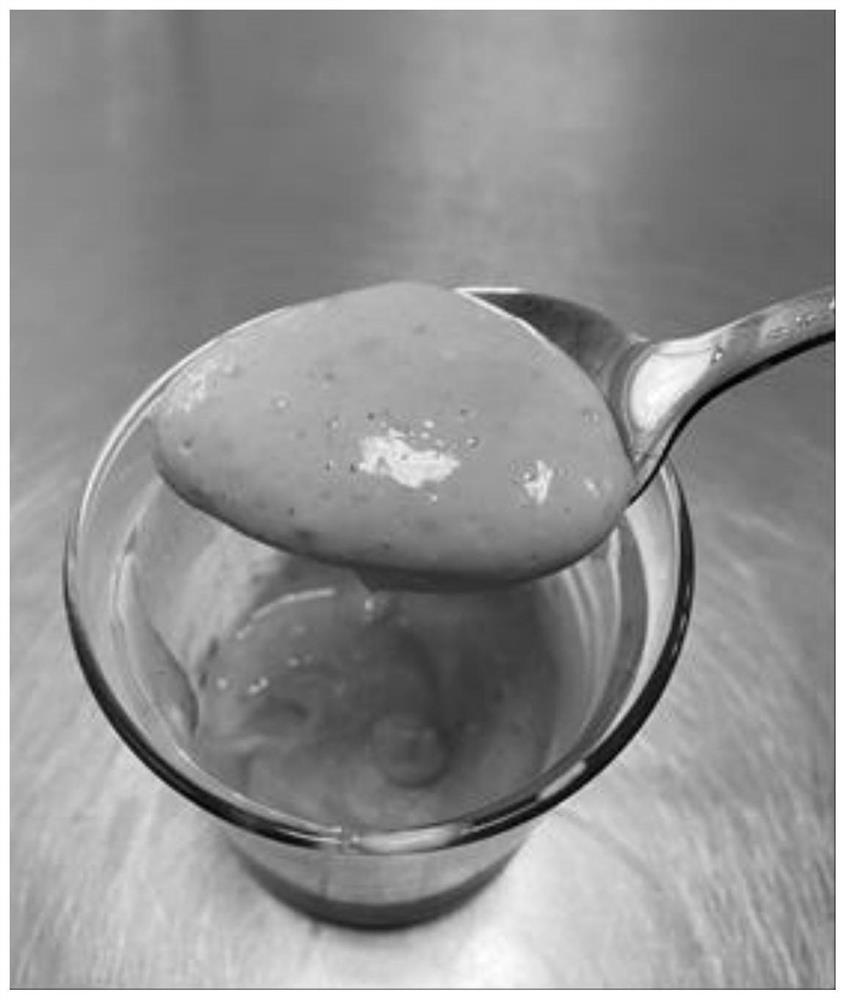

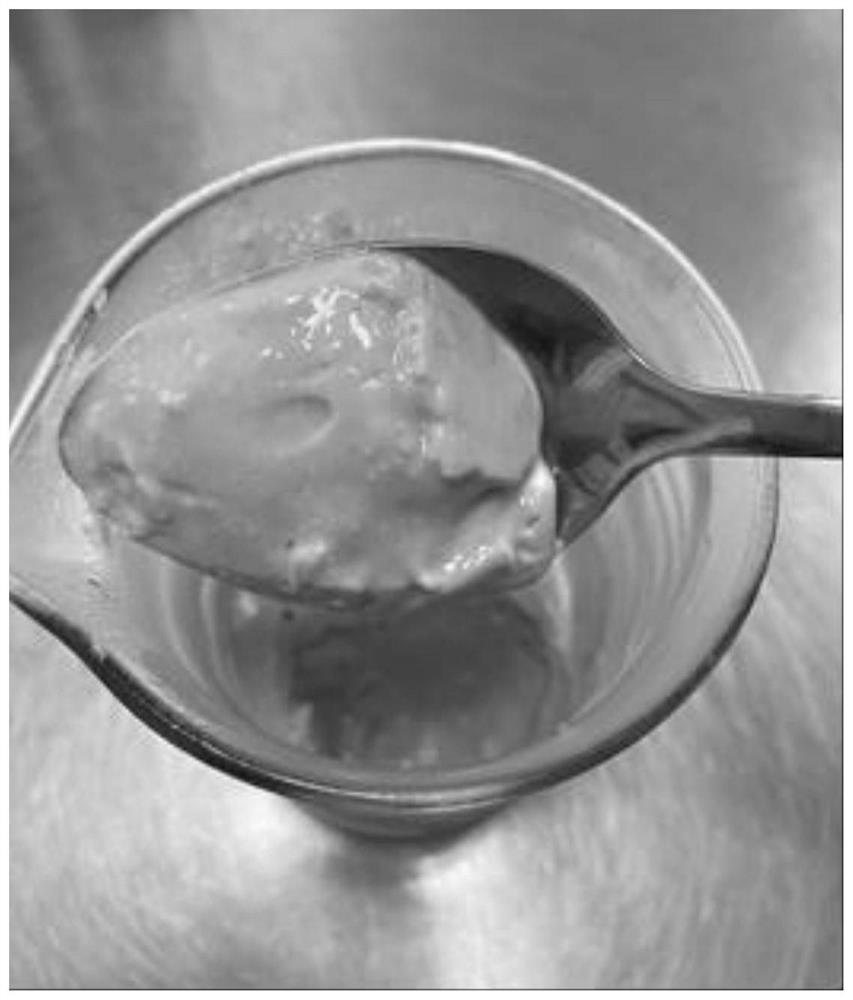

[0048] Such as figure 2 , image 3 As shown, the pe...

Embodiment 3

[0051] The product prepared by the invention is compared with the product prepared by the prior art, and the results are as follows:

[0052] Table 1 invention scheme and existing scheme nutrient substance comparison

[0053]

[0054] The invention has high viscosity and is easy to lick; the invention has a significantly high content of lactic acid bacteria, which can inhibit the growth of harmful bacteria in the intestinal tract of pets; the invention has high protein, fat, and collagen content and richer nutrition

[0055] Table 2 invention scheme and existing scheme flavor substance contrast

[0056]

[0057] The invention scheme detects eucalyptol, linalool, phenylethyl alcohol, 2-nonanone, 3-hydroxy-2-butanone, dimethyl disulfide, and 2-acetyl-1-pyrroline flavor substances, which are produced The key flavor substance of the meat aroma makes the food-inducing aroma strong.

[0058] Table 3 invention scheme and existing scheme amino acid content comparison

[0059] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com