Preparation method of iron sucrose injection with low variable iron content

A technology for the preparation of injections and iron sucrose, which is applied to the preparation of sugar derivatives, chemical instruments and methods, and medical preparations containing active ingredients, etc., can solve the problems of narrow molecular weight of iron sucrose and does not involve variable iron content, etc., to achieve Improve the quality level, the production process is stable and controllable, and the effect of uniform and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: preparation of iron sucrose injection

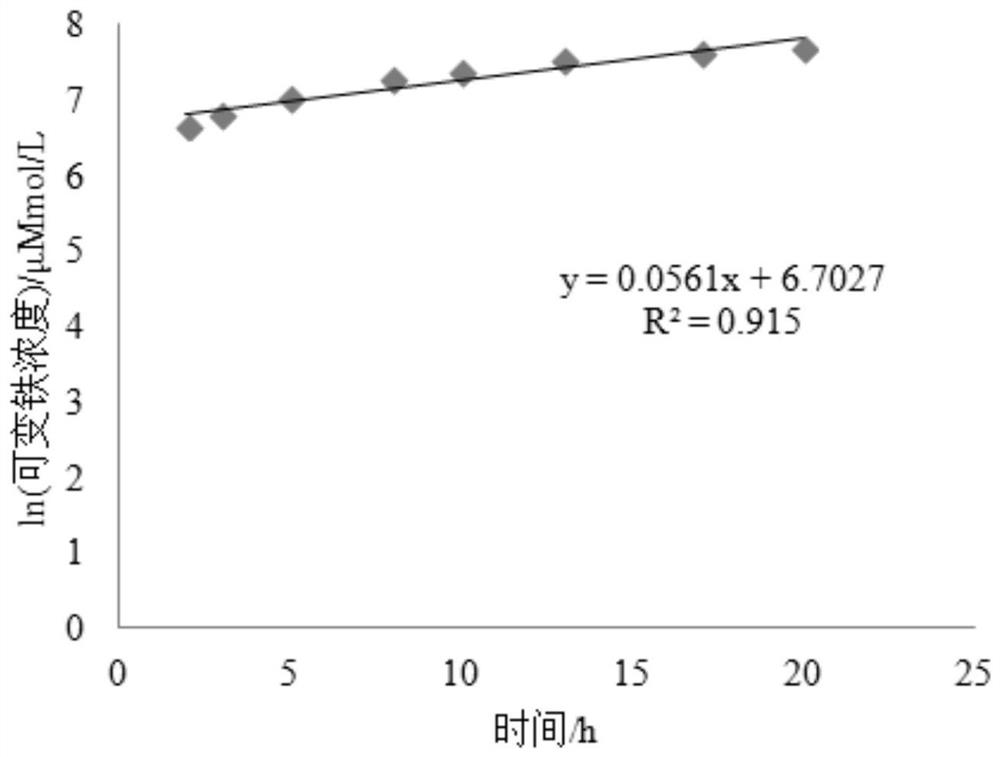

[0030] Weigh the iron sucrose raw material and water for injection with a mass ratio of 1:1.5 and add them to the liquid preparation tank, stir and dissolve, the temperature of the first water distillation concentration is 103 ° C, the time of water distillation is 1.5 h, and the temperature of the second water distillation concentration is 108 °C ℃, distilled and concentrated for 1 hour, the temperature of the third distilled and concentrated water is 120 ℃, and the time of distilled water is 1.5 hours, then add distilled water for injection, stir and dilute, after cooling to room temperature, add hydrochloric acid solution to adjust the pH to 10.5-11.0 , using a 0.22 μm PES filter membrane to circulate and filter 3 times, sterilize at 121°C for 15 minutes, and fill to obtain iron sucrose injection, the concentration is 20mgFe / mL (calculated as iron), and the content of variable iron is 2.21%. Ferrokinetic curve fit...

Embodiment 2

[0031] Embodiment 2: preparation of iron sucrose injection

[0032] Weigh the iron sucrose raw material and water for injection with a mass ratio of 1:3.5 and add them to the liquid mixing tank, stir and dissolve, the temperature of the first steamed water concentration is 104°C, the time of steamed water is 1.5h, and the temperature of the second steamed water concentrated Concentrate with distilled water at 110°C for 1.7 hours. The temperature for the third distilled water concentration is 117°C, and the time for distilled water is 1.2 hours. Then add distilled water for injection, stir and dilute, and after cooling to room temperature, add hydrochloric acid solution to adjust the pH to 10.5 ~11.0, filtered 4 times with a 0.22 μm PES circulating filter, sterilized at 121°C for 18 minutes, filled to obtain iron sucrose injection, the concentration is 20mgFe / mL (calculated as iron), and the content of variable iron is 2.10%. The correlation coefficient of variable ferrokinetic...

Embodiment 3

[0033] Embodiment 3: preparation of iron sucrose injection

[0034] Weigh the iron sucrose raw material and water for injection with a mass ratio of 1:2.2 and add them to the liquid mixing tank, stir and dissolve, the temperature of the first steamed water concentration is 103°C, the time of steamed water is 1.8h, and the temperature of the second steamed water concentrated 109°C, distilled and concentrated for 1.6h, the third time of distilled water was concentrated at 120°C, and the time of distilled water was 1.3h, then add distilled water for injection, stir and dilute, after cooling to room temperature, add hydrochloric acid solution to adjust the pH to 10.5 ~11.0, using 0.1 μm PES filter membrane to circulate and filter for 3 times, sterilize at 121°C for 20 minutes, and fill to prepare iron sucrose injection, the concentration is 20mgFe / mL (calculated as iron), and the content of variable iron is 2.09%. The correlation coefficient of variable ferrokinetic curve fitting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com