Preparation method of WS2/FeS nanosphere hybrid catalyst and application thereof

A technology of catalysts and nanospheres, applied in the fields of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of no WS2 and FeS phase mixture research, no disclosure of the performance advantages and disadvantages of WS2 and FeS phase mixtures, etc. problems, to achieve the effect of controllable shape, uniform size and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

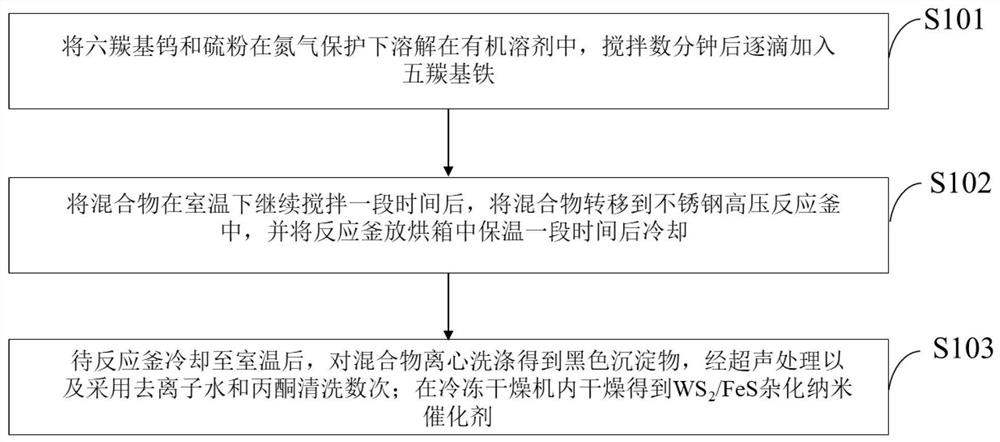

[0035] like figure 1 As shown, the WS provided by the present invention 2 The preparation method of FeS nanosphere hybrid catalyst comprises the following steps:

[0036] S101: Dissolving tungsten hexacarbonyl and sulfur powder in an organic solvent under the protection of nitrogen, stirring for several minutes, then adding iron pentacarbonyl dropwise;

[0037]S102: After continuing to stir the mixture at room temperature for a period of time, the mixture is transferred to a stainless steel high-pressure reactor, and the reactor is placed in an oven to keep warm for a period of time and then cooled;

[0038] S103: After the reactor was cooled to room temperature, the mixture was centrifuged and washed to obtain a black precipitate, which was subjected to ultrasonic treatment and washed several times with deionized water and acetone; dried in a freeze dryer to obtain WS 2 / FeS nanosphere hybrid catalyst.

[0039] The WS provided by the embodiment of the present invention 2 ...

Embodiment 1

[0049] Example 1: Preparation of WS according to the invention 2 / FeS nanosphere hybrid catalyst

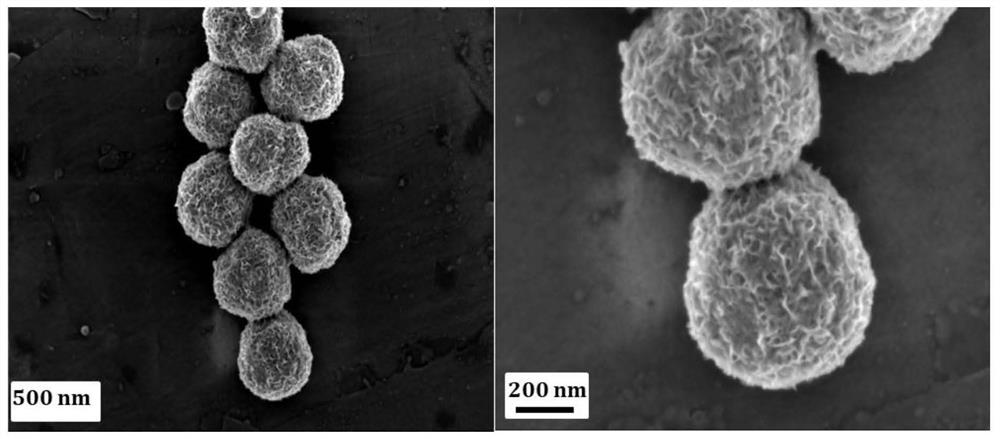

[0050] First, 0.33g of sublimed sulfur powder and 0.6g; 0.88g; 1.23g of tungsten hexacarbonyl were dissolved in three parts of 35mL organic solvent under the protection of nitrogen, and fully stirred. Then, 1 mL of iron pentacarbonyl was added dropwise under the protection of nitrogen. Then, the mixture was rapidly magnetically stirred at room temperature for 20 min, then the mixture was transferred to a stainless steel autoclave, and the autoclave was placed in an oven at 230 ° C for 24 h; finally, the autoclave was cooled to room temperature, The mixture was washed by centrifugation to obtain a black precipitate. The above black precipitate was ultrasonically dispersed, washed alternately with deionized water and acetone several times, finally collected by centrifugation, and dried in a vacuum freeze dryer for 2 hours to obtain a black product.

[0051] The properties of the ...

Embodiment 2

[0055] Embodiment 2: WS provided by the embodiment of the present invention 2 / FeS nanosphere hybrid catalyst comprises the following steps:

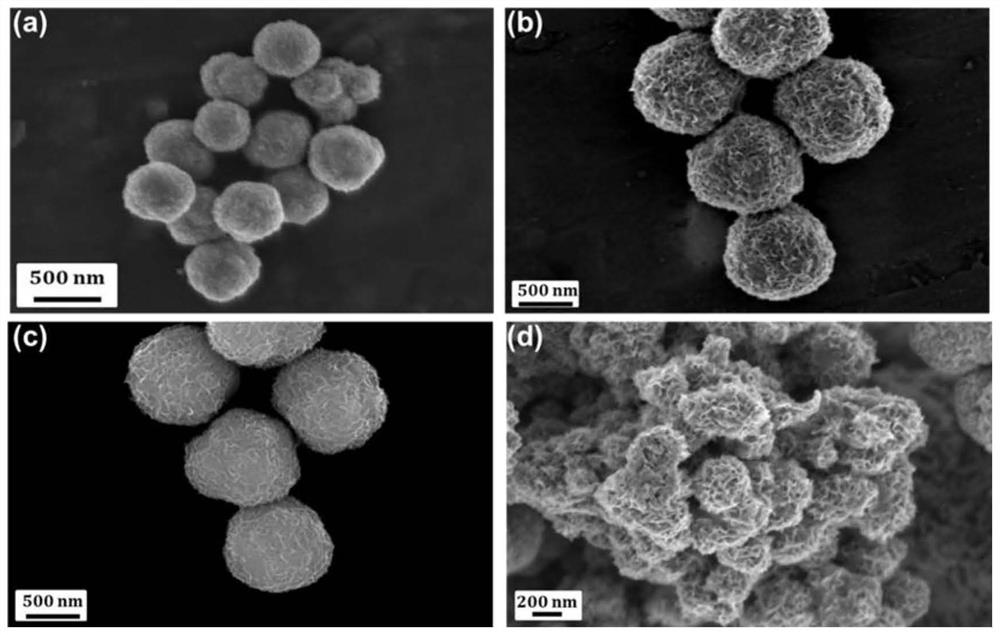

[0056] Firstly, under the protection of nitrogen, 0.5g of sublimed sulfur powder and 0.6g; 0.88g; 1.23g of tungsten hexacarbonyl were dissolved in three parts of 35mL organic solvent, and fully stirred. Then, 1 mL of iron pentacarbonyl was added dropwise under the protection of nitrogen. Then, the mixture was rapidly magnetically stirred at room temperature for 20 min, then the mixture was transferred to a stainless steel autoclave, and the autoclave was placed in an oven at 230 ° C for 24 h; finally, the autoclave was cooled to room temperature, The mixture was washed by centrifugation to obtain a black precipitate. The above black precipitate was ultrasonically dispersed, washed alternately with deionized water and acetone several times, finally collected by centrifugation, and dried in a vacuum freeze dryer for 2 hours to obtain a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com