Engine exhaust pipe and preparation process thereof

A preparation process and exhaust pipe technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems such as the adverse effect of the service life of the exhaust pipe, the inability to withstand the strong vibration of the engine, and the easy occurrence of cracks in the exhaust pipe. Achieve high stability, improve heat resistance, and improve anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

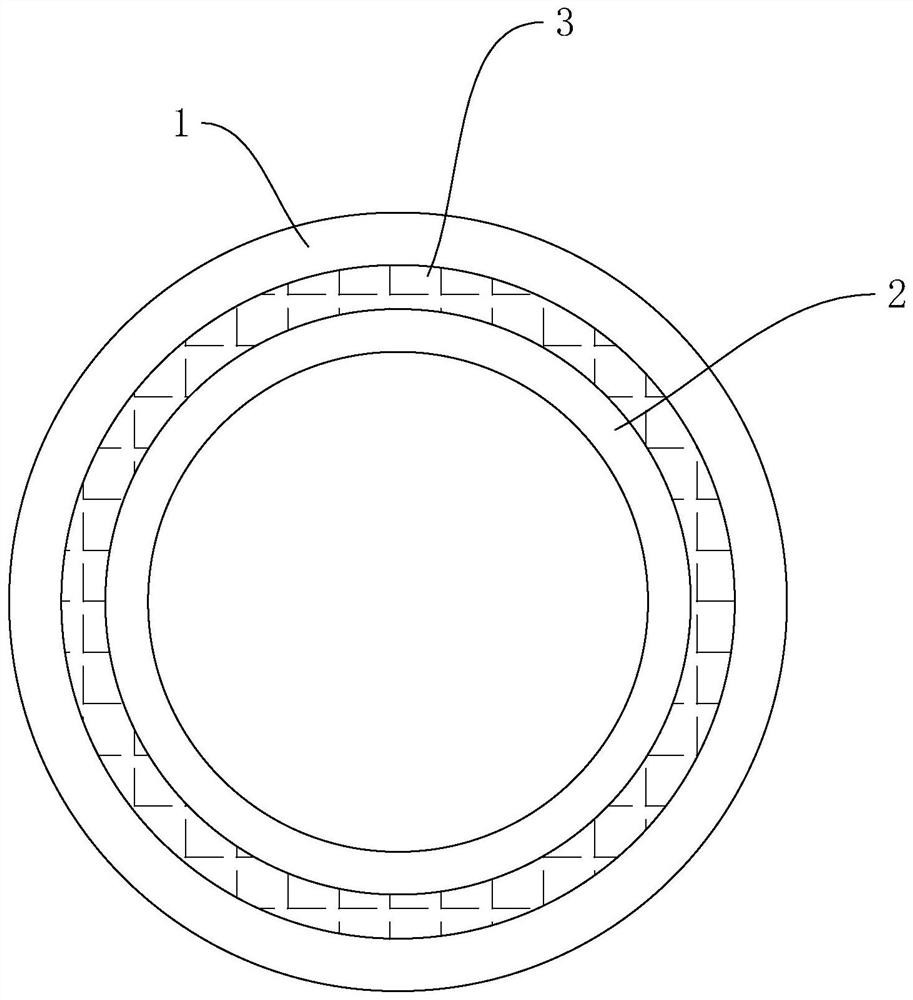

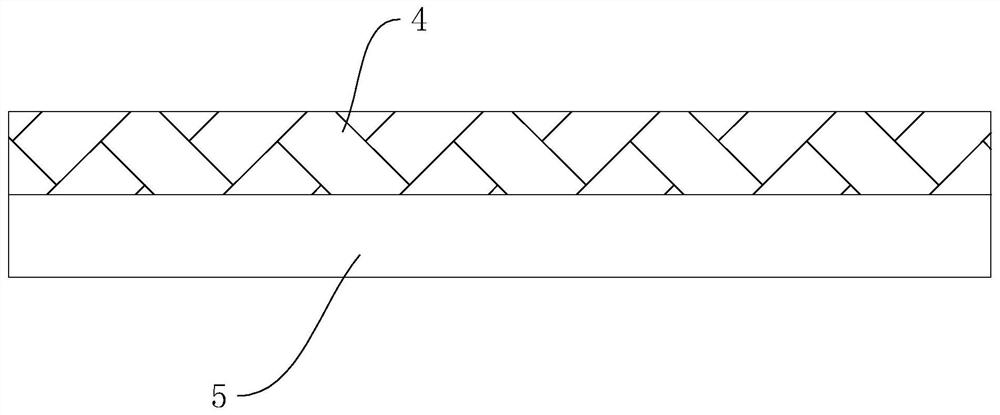

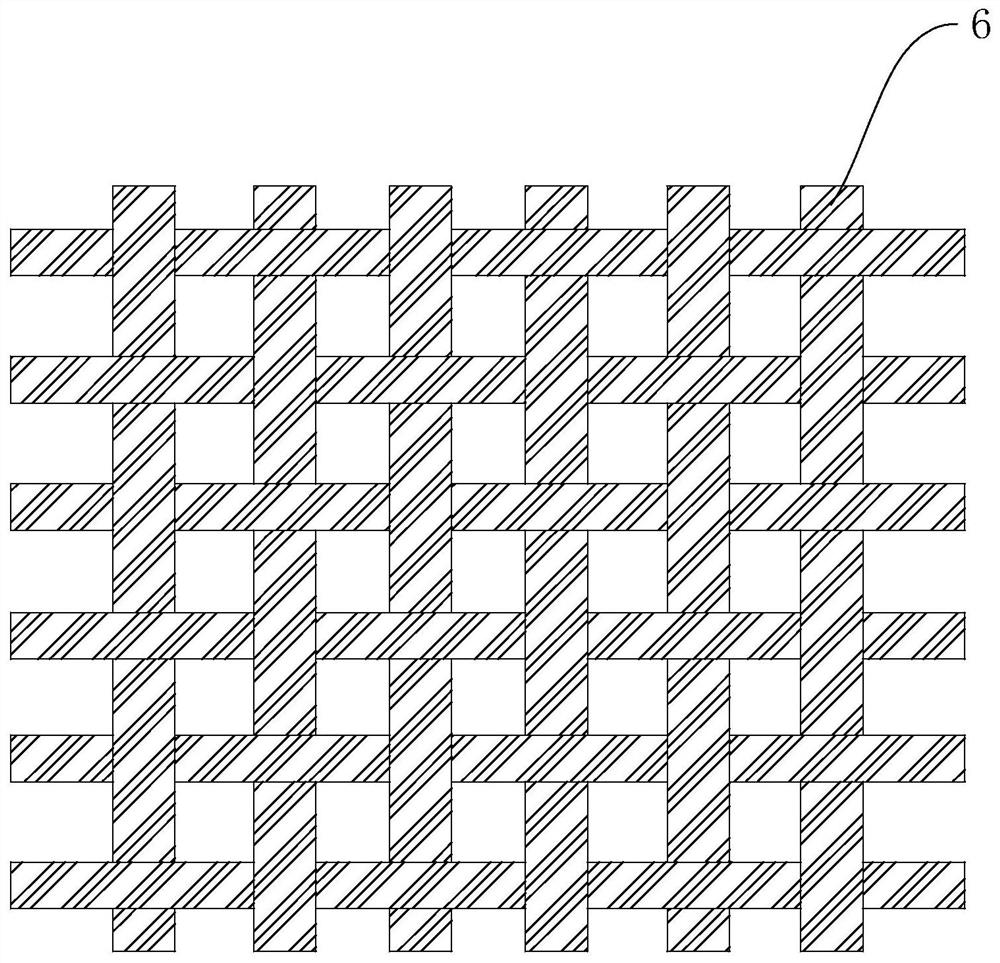

[0047] see Figure 1 to Figure 4 As shown, an engine exhaust pipe includes an outer pipe layer 1 and an inner pipe layer 2. A heat insulating layer 3 is arranged between the inner pipe layer 2 and the outer pipe layer 1. The heat insulating layer 3 is made of carbon fiber composite fabric, and the carbon fiber composite The fabric includes a reinforcement layer 4 and a thermal insulation layer 5 composited with the reinforcement layer 4 by impregnating resin. The reinforcement layer 4 is woven from a number of reinforcement yarns 6 in warp and weft. The reinforcement yarn 6 is twisted from a number of carbon fibers. It is braided with a number of wefts 8 warp and weft, the warp 7 is twisted by a number of glass fibers, the weft 8 is twisted by a number of ceramic fibers, the inner tube layer 2 and the outer tube layer 1 are made of heat-resistant ferritic stainless steel , its raw materials and chemical composition mass percentages are: C-0.08%, Si-0.9%, Mn-0.44%, P-0.003%, S-...

Embodiment 2

[0049] see Figure 1 to Figure 4 As shown, an engine exhaust pipe includes an outer pipe layer 1 and an inner pipe layer 2. A heat insulating layer 3 is arranged between the inner pipe layer 2 and the outer pipe layer 1. The heat insulating layer 3 is made of carbon fiber composite fabric, and the carbon fiber composite The fabric includes a reinforcement layer 4 and a thermal insulation layer 5 composited with the reinforcement layer 4 by impregnating resin. The reinforcement layer 4 is woven from a number of reinforcement yarns 6 in warp and weft. The reinforcement yarn 6 is twisted from a number of carbon fibers. It is braided with a number of wefts 8 warp and weft, the warp 7 is twisted by a number of glass fibers, the weft 8 is twisted by a number of ceramic fibers, the inner tube layer 2 and the outer tube layer 1 are made of heat-resistant ferritic stainless steel , its raw materials and chemical composition mass percentages are: C-0.1%, Si-1.12%, Mn-1.34%, P-0.011%, S-...

Embodiment 3

[0051] A process for preparing an engine exhaust pipe, for preparing an engine exhaust pipe, comprising the following steps:

[0052] S1: Proportioning raw materials, weighing a certain amount of heat-resistant ferritic stainless steel raw materials, and preparing a certain amount of Fe for use;

[0053] S2: Raw material smelting. Pour a certain amount of raw materials, FE and unavoidable impurities prepared in step S1 into the melting furnace for high-temperature heating and smelting. When the temperature in the melting furnace rises to 1550°C, continue smelting for 1.5 to 2.5 hours. Then take samples so that the mass percentage of each chemical component in the furnace charge is within the following control range in the spectrometer detection: C-0.08%~0.1%, Si-0.9%~1.12%, Mn-0.44%~1.34%, P-0.003% ~0.011%, S-0.002%~0.008%, Cr-16.9%~19.14%, Al-0.95%~1.01%, Ti-0.4%~0.8%, Mo-0.75%~1.25%, you can get mixed metal liquid ;

[0054] S3: raw material refining, passing the mixed met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com