Automatic yeast block production line

A production line and curved block technology, which is applied in the field of brewing, can solve the problems of low efficiency and high labor intensity, and achieve the effect of simple design structure, easy maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

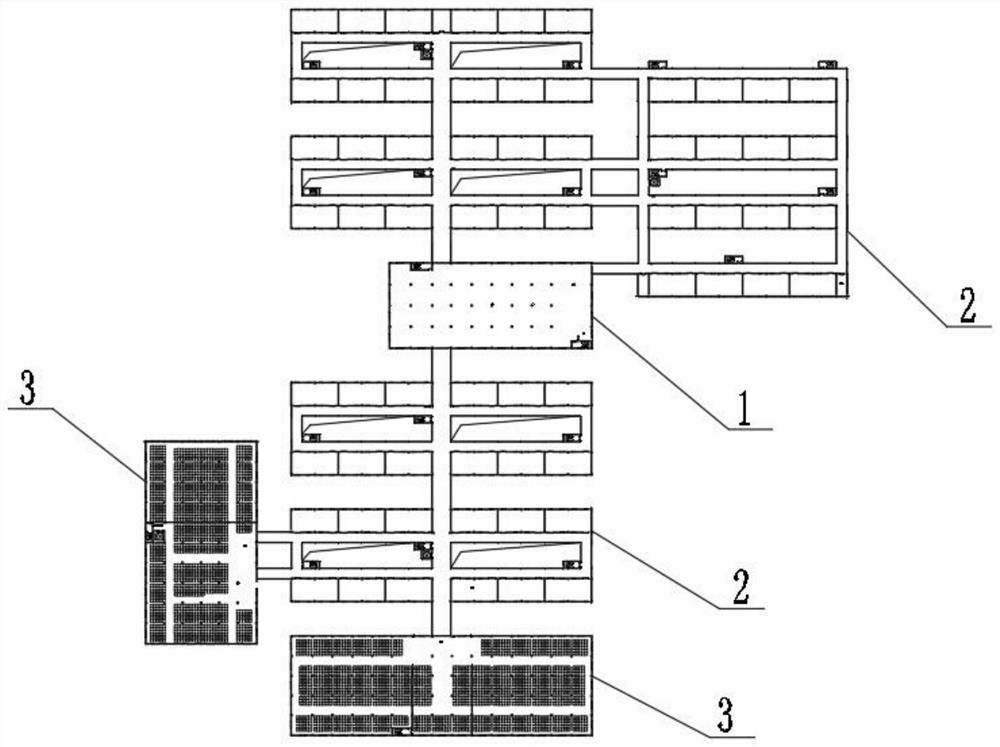

[0076] refer to figure 1 , figure 2 and image 3 , the automatic curved block production line of the present invention comprises:

[0077] The koji making system is arranged in the koji making workshop 1 for making koji pieces 4;

[0078] The fermentation system is used to transfer the koji block to the koji room 2 for fermentation;

[0079] Packing system, arranged in the music library 3, for packing music pieces;

[0080] overturning system;

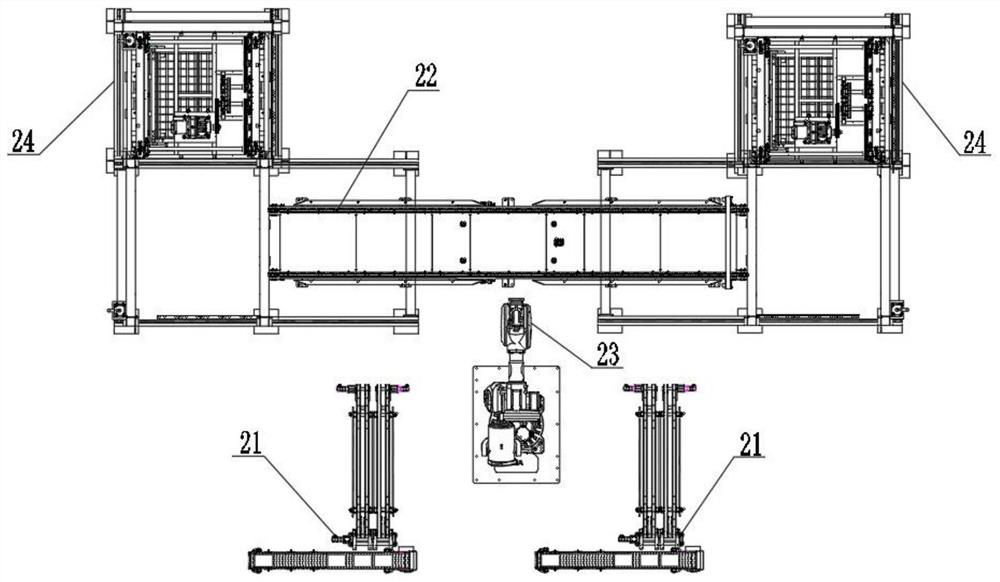

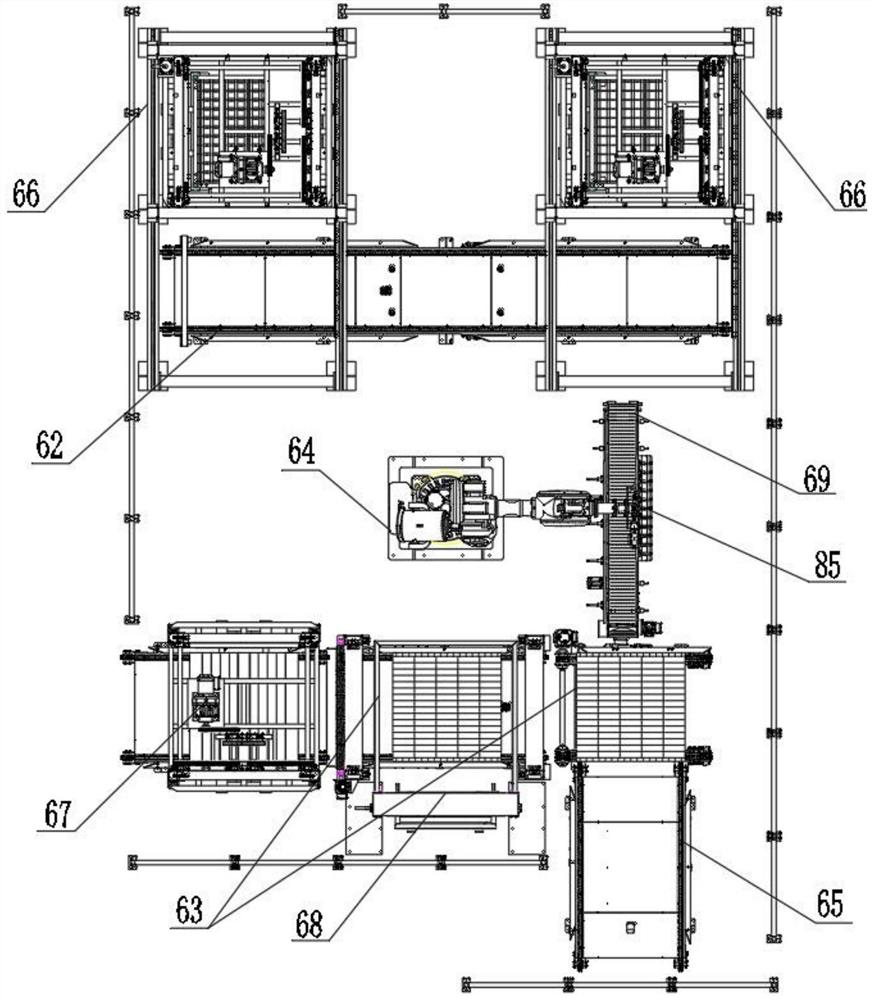

[0081] The fermentation system includes a backpack-type AGV robot 11 and a bent rack 12 stacked on the backpack-type AGV robot; the turning system is used to turn over the bent rack; the bent room 2 is arranged between the koji workshop 1 and the koji storehouse 3; Comprising a koji making machine (not shown in the figure), a koji-joining mechanism 21 connected to the koji-making machine, a first conveying line 22 arranged on the side of the koji-making mechanism, a koji mechanism arranged between the koji-joining mechanism and the...

Embodiment 2

[0105] The difference between this embodiment and Embodiment 1 is that the mechanisms of the first floating clamping mechanism, the second floating clamping mechanism and the third floating clamping mechanism are different. The first floating clamping mechanism and the second floating clamping mechanism of this embodiment Both the clamping mechanism and the third floating clamping mechanism adopt diaphragm cylinders. The diaphragm cylinder has the characteristics of short stroke, stable operation, stable output, and simple structure. It is suitable for working objects with low strength and meets the clamping of the curved block in this scheme. It is flexibly connected with the curved block to better protect the curved block.

Embodiment 3

[0107] refer to Figure 21, on the basis of Embodiment 1, this embodiment is provided with a damping mechanism for buffering the fall of the curved block on the side plate; the side plate 73 includes a long plate 7301 and a short plate 7302, and the height of the long plate matches the height of the curved block. The height of the short plate is less than the height of the long plate; the damping mechanism includes a push plate 81 arranged on the bottom of the long plate and parallel to the short plate and a third cylinder 82 that drives the push plate to expand and contract towards the short plate; the fixed end of the third cylinder is connected to the long plate Fixed connection, the movable end of the third cylinder links to each other with push plate. When the curved block is unloaded on the pallet, the third cylinder drives the push plate to extend, so that the push plate approaches and contacts the curved block, the second floating clamping mechanism is released, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com