A kind of sludge dehydrating agent and its application method for reducing the moisture content of sludge and utilizing it as a resource

A technology of sludge dehydrating agent and water content, which is applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve problems such as limited dehydration effect, secondary pollution, complex components, etc. The effect of high mud resource utilization rate, improved calorific value, and wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

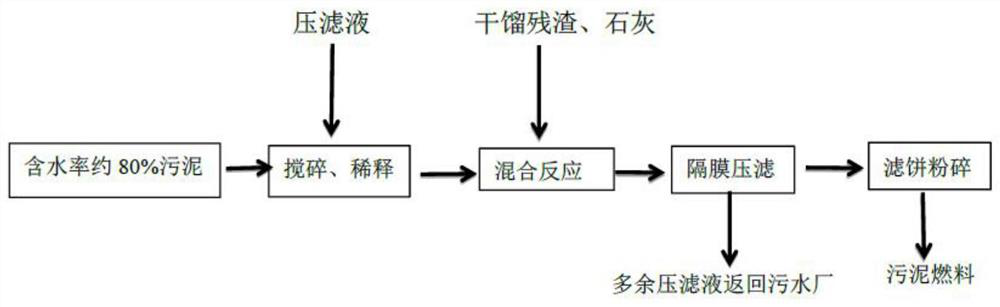

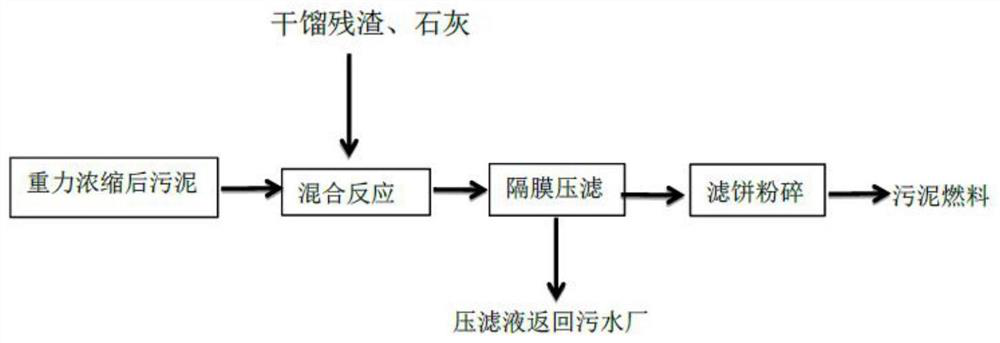

Method used

Image

Examples

Embodiment 1

[0044] The sludge comes from a sludge treatment and disposal site in Changsha, Hunan, with a moisture content of 78.6%. Add an appropriate amount of middle water, crush and dilute to prepare a total of 50kg of sludge with a water content of 96%, adjust its pH to 8 with lime, and then press W 干馏残渣 :W 干污泥 =0.8:1.0 mass ratio, add 1.60 kg of dry distillation residue made from non-caking coal at 650-700 °C and processed into a particle size range of 30-500 μm, react for 30 minutes under stirring, and then pump to an area of 0.5 m 2 , Diaphragm filtration is carried out on a XAYG0.5 / 630-U high-pressure diaphragm filter press with a squeezing pressure of 1.6MPa. Finally, 5.42kg of sludge filter cake is obtained, and its technical indicators are: moisture Mt is 37.20%, calorific value Qad,net is 3115kCal / kg, ash content Aad is 31.62%, volatile matter Vad is 31.01%, and sulfur content St,ad is 0.30 %, pH 8, can meet the requirements of continuous autonomous combustion.

Embodiment 2

[0046] The sludge comes from the sludge treatment and disposal center of Xiangtan City, Hunan Province, with a moisture content of 77.5%. Add an appropriate amount of press filtrate from previous tests, crush and dilute to prepare a total of 55 kg of sludge with a water content of 95%, adjust its pH to 10 with lime, and then press W 干馏残渣 :W 干污泥 =0.3:1.0 mass ratio, add 0.83kg of dry distillation residue made from weak caking coal at 650-700℃ and processed into a particle size range of 30-500μm, react for 15min under stirring, and then pump to an area of 0.5m 2 , Diaphragm filtration is carried out on a XAYG0.5 / 630-U high-pressure diaphragm filter press with a squeezing pressure of 1.9MPa. Finally, 5.31kg of sludge filter cake is obtained, and its technical indicators are: moisture Mt is 36.11%, calorific value Qad,net is 2406kCal / kg, ash content Aad is 34.51%, volatile matter Vad is 31.16%, and sulfur content St,ad is 0.15 %, pH10, can meet the requirements of continuous s...

Embodiment 3

[0048] The sludge comes from a sludge treatment and disposal site in Henan, with a moisture content of 79.2%. Add an appropriate amount of press filtrate from previous tests, crush and dilute to prepare a total of 100kg of sludge with a water content of 98%, adjust its pH to 9 with lime, and then press W 干馏残渣 :W 干污泥 =0.8:1.0 mass ratio, add 1.60 kg of dry distillation residue made from non-caking coal at 650-700 °C and processed into a particle size range of 30-500 μm, react for 30 minutes under stirring, and then pump to an area of 0.5 m 2 , Diaphragm filtration is carried out on a XAYG0.5 / 630-U high-pressure diaphragm filter press with a squeezing pressure of 1.7MPa. Finally, get 5.60kg of sludge filter cake, its technical indicators: moisture Mt is 39.30%, calorific value Qad,net is 3788kCal / kg, ash content Aad is 20.36%, volatile matter Vad is 36.85%, sulfur content St,ad is 0.32 %, pH 9, can meet the requirements of sustained autonomous combustion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com