Perovskite-like thermistor material and preparation method thereof

A thermistor, perovskite-type technology, applied in the field of perovskite-like thermistor materials and their preparation, can solve problems such as applications that have not received research attention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

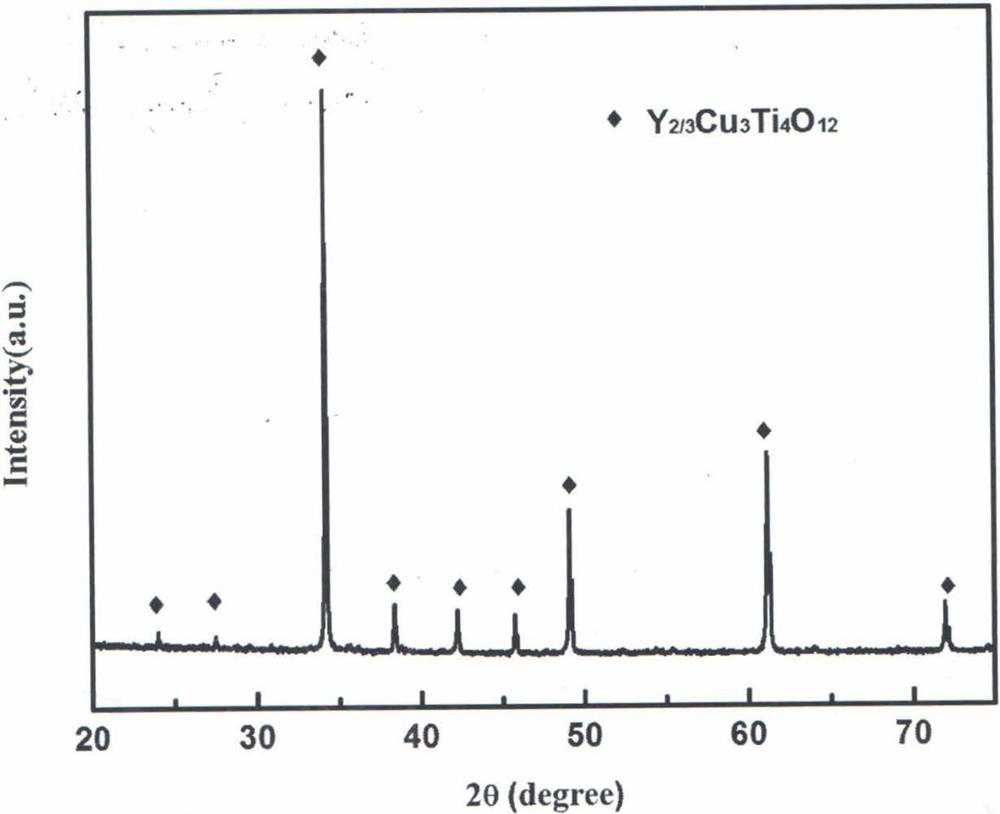

Image

Examples

Embodiment 1

[0016] a. Press Y 2 / 3 Cu 3 Ti 3.9 mn 0.1 o 12 The composition of x=0.1 weighs respectively 2.1622g of yttrium nitrate hexahydrate, 6.1934g of copper nitrate trihydrate, 11.3414g of tetrabutyl titanate, and 0.30227g of manganese nitrate tetrahydrate is dissolved in 99% ethanol to form a mixed solution, Add 250ml of ethylene glycol and 20g of citric acid, and stir for 1 hour by magnetic force to obtain a blue liquid sol;

[0017] b. Heating the blue liquid sol obtained in step a on a heating plate at a temperature of 120° C. to dehydrate until a gel is formed. After the gel is dried at a temperature of 150° C., a loose brown ash powder is obtained;

[0018] c. Grind the powder obtained in step b in a mortar and decompose it at a temperature of 350°C for 1 hour, then grind the powder again and calcinate it at a temperature of 600°C for 5 hours to obtain Y 2 / 3 Cu 3 Ti 3.9 mn 0.1 o 12 Powder;

[0019] d, the powder material that step c obtains is with 10Kg / cm 2 The press...

Embodiment 2

[0022] a. Press Y 2 / 3 Cu 3 Ti 3.7 mn 0.3 o 12 The composition of x=0.3 weighs respectively 2.1596g of yttrium nitrate hexahydrate, 6.1860g of copper nitrate trihydrate, 10.7407g of tetrabutyl titanate, and 0.90722g of manganese nitrate tetrahydrate is dissolved in 99% ethanol to form a mixed solution, Add 250ml of ethylene glycol and 20g of citric acid, and stir for 1.5 hours by magnetic force to obtain a blue liquid sol;

[0023] b. Heating the blue liquid sol obtained in step a on a heating plate at a temperature of 120° C. to dehydrate until a gel is formed. After the gel is dried at a temperature of 150° C., a loose brown ash powder is obtained;

[0024] c. Grind the powder obtained in step b in a mortar and decompose it at a temperature of 350°C for 1.5 hours, then grind the powder again and calcinate it at a temperature of 650°C for 5.5 hours to obtain Y 2 / 3 Cu 3 Ti 3.7 mn 0.3 o 12 Powder;

[0025] d, the powder material that step c obtains is with 12Kg / cm 2 T...

Embodiment 3

[0028] a. Press Y 2 / 3 Cu 3 Ti 3.5 mn 0.5 o 12 The composition of x=0.5 weighs respectively 2.1570g of yttrium nitrate hexahydrate, 6.1787g of copper nitrate trihydrate, 10.1539g of tetrabutyl titanate, and 1.5102g of manganese nitrate tetrahydrate is dissolved in 99% ethanol to form a mixed solution, Add 250ml of ethylene glycol and 20g of citric acid, and stir for 2 hours by magnetic force to obtain a blue liquid sol;

[0029] b. Heating the blue liquid sol obtained in step a on a heating plate at a temperature of 120° C. to dehydrate until a gel is formed. After the gel is dried at a temperature of 150° C., a loose brown ash powder is obtained;

[0030] c. Grind the powder obtained in step b in a mortar and decompose it at a temperature of 350°C for 2 hours, then grind the powder again and calcinate it at a temperature of 700°C for 6 hours to obtain Y 2 / 3 Cu 3 Ti 3.5 mn 0.5 o 12 Powder;

[0031] d, the powder material that step c obtains is with 14Kg / cm 2 The pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Material constant | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com