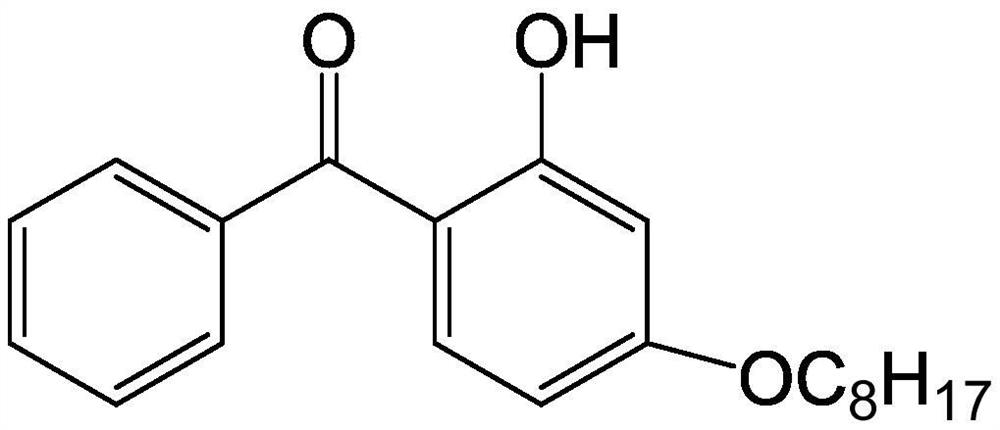

Novel process for preparing sun-screening agent 2-hydroxy-4-n-octyloxy benzophenone

A technology of n-octyloxybenzophenone and dihydroxybenzophenone, which is applied in the preparation of carbon-based compounds, organic compounds, organic chemistry, etc., to reduce the generation of waste water and residue, easy to control the intermediate reaction process, The effect of reducing the three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

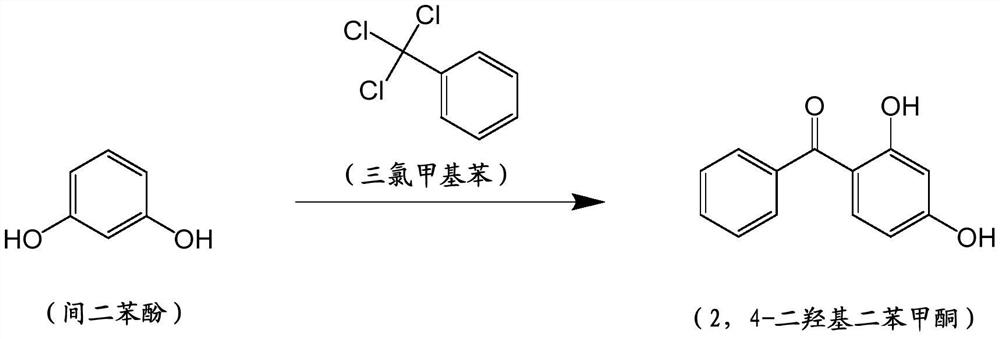

[0093] Preparation of 2,4-dihydroxybenzophenone

[0094] Add 660.6g of 10% ethanol-water solution and 110.1g of resorcinol into a 2000mL four-necked glass reaction flask equipped with a stirrer, thermometer, dropping funnel and condenser, and start stirring.

[0095] The system was heated to 60°C, and 234.6 g of trichloromethylbenzene was slowly added dropwise within 2 hours. After the dropwise addition, the reaction was continued at 80°C for 6 hours.

[0096] Add toluene for extraction, and the oil layer is 2,4-dihydroxybenzophenone required for the preparation of 2-hydroxy-4-n-octyloxybenzophenone.

Embodiment 2

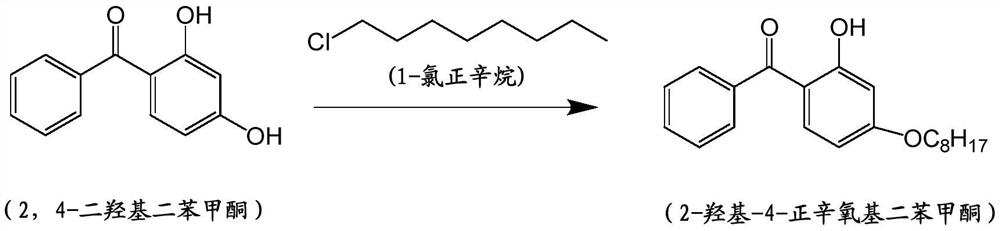

[0098] Preparation of 2-hydroxy-4-n-octyloxybenzophenone

[0099] In a 1000mL four-necked glass reaction flask, add 1200g of toluene, 400g of 2,4-dihydroxybenzophenone, 330g of 1-chloro-n-octane, and 120g of potassium carbonate in sequence, in which 2,4-dihydroxybenzophenone is Embodiment 1 gains.

[0100] Heat the temperature to 80°C, keep it warm for 6 hours until the reaction of the raw materials is complete, raise the temperature to 110°C, adjust the pressure to -0.1MPa for precipitation, then raise the temperature to 220°C, adjust the pressure to 1mmHg for distillation, and finally add ethanol to recrystallize to obtain 2-Hydroxy-4-n-octyloxybenzophenone, yield 90%.

Embodiment 3

[0102] Preparation of 2-hydroxy-4-n-octyloxybenzophenone

[0103] In a 1000mL four-necked glass reaction flask, add 1200g of N-N dimethylformamide, 400g of 2,4-dihydroxybenzophenone, 330g of 1-chloro-n-octane, and 120g of catalyst sodium carbonate in sequence.

[0104] Heat the temperature to 70°C, keep it warm for 8 hours, until the raw materials are completely reacted, raise the temperature to 120°C, adjust the pressure to -0.1MPa for precipitation, then raise the temperature to 230°C, adjust the pressure to 1mmHg for distillation, and finally add ethanol for recrystallization 2-Hydroxy-4-n-octyloxybenzophenone was obtained with a yield of 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com