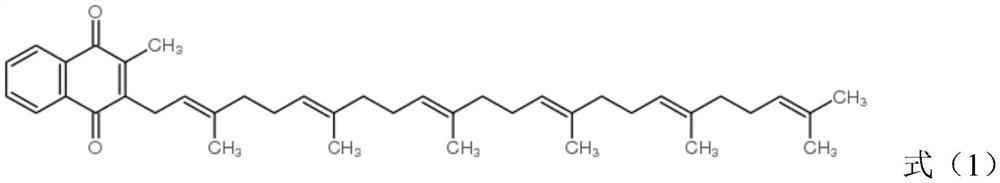

Equipment and method for extracting vitamin K2 from microbial fermentation liquor

A technology for microbial fermentation broth and vitamins, applied in organic chemistry, quinone separation/purification, etc., can solve problems such as cumbersome process, low purity and/or yield of vitamin K2, achieve high concentration, large sample volume, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

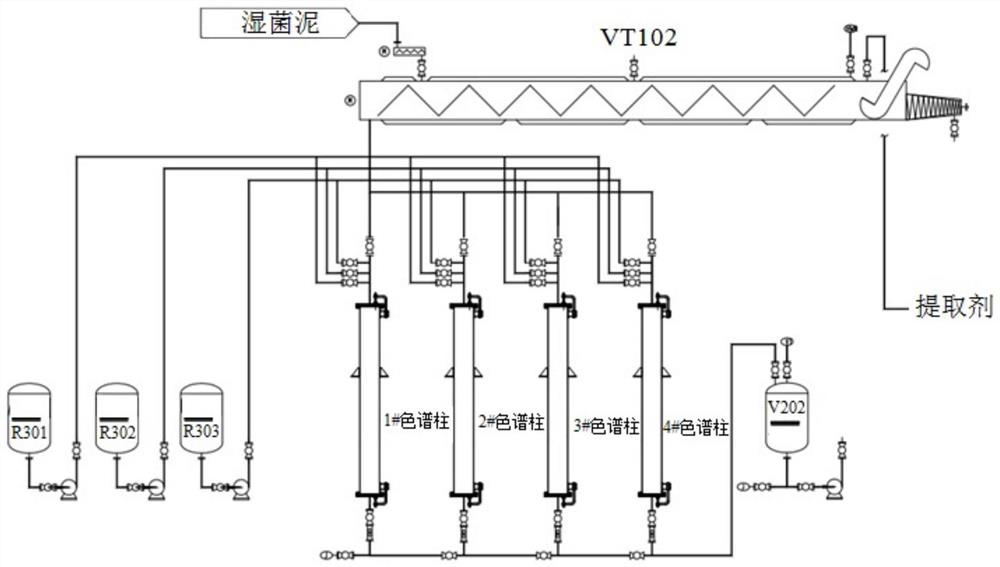

[0049] Embodiment 1 (reversed-phase chromatographic column)

[0050] In this embodiment, vitamin K2 (MK-7) is separated, extracted and purified from microbial fermentation broth by means of continuous dynamic countercurrent extraction combined with medium-pressure preparative chromatographic separation and purification. The specific steps are as follows:

[0051] (1) 50 L of the vitamin K2 stock solution produced by Bacillus subtilis fermentation was subjected to wall-breaking treatment with concentrated sulfuric acid, and then solid-liquid separation was performed by a tubular centrifuge to obtain 3.0 kg of wet sludge. The wet sludge and acetone-ethanol mixed solvent (v:v=1:2) are subjected to dynamic countercurrent extraction in a continuous dynamic countercurrent extractor (length-to-diameter ratio is 30:1) according to the mass volume ratio of 1kg:10L, and the extraction is controlled. The temperature is 40° C., the extraction residence time is 1 h, and an extract solution...

Embodiment 2

[0054] Embodiment 2 (reversed-phase chromatographic column)

[0055] In this embodiment, vitamin K2 (MK-7) is extracted and purified from microbial fermentation broth by means of continuous dynamic countercurrent extraction combined with medium-pressure preparative chromatographic separation and purification. The specific steps are as follows:

[0056] (1) 50 L of the vitamin K2 stock solution produced by the fermentation of Bacillus subtilis was broken with concentrated hydrochloric acid, and then solid-liquid separation was performed with a tubular centrifuge to obtain 3.2 kg of wet sludge. The wet sludge and methanol-dichloromethane mixed solvent (v:v=3:1) were subjected to dynamic countercurrent extraction in a continuous dynamic countercurrent extractor (length-to-diameter ratio of 100:1) at a mass volume ratio of 1kg:8L, The extraction temperature was controlled at 30° C., the extraction residence time was 1 h, and an extract solution with a vitamin K2 (MK-7) concentrati...

Embodiment 3

[0059] Embodiment 3 (reversed-phase chromatographic column)

[0060] In this embodiment, vitamin K2 (MK-7) is separated, extracted and purified from microbial fermentation broth by means of continuous dynamic countercurrent extraction combined with medium-pressure preparative chromatographic separation and purification. The specific steps are as follows:

[0061] (1) 3m3 of the vitamin K2 stock solution produced by the fermentation of Bacillus subtilis was subjected to wall-breaking treatment with acetic acid, and then solid-liquid separation was carried out by a butterfly centrifuge to obtain 180 kg of wet sludge. The wet sludge and methanol-ethyl acetate mixed solvent (v:v=3:1) were subjected to dynamic countercurrent extraction in a continuous dynamic countercurrent extractor (length-to-diameter ratio of 60:1) at a mass volume ratio of 1kg:10L, The extraction temperature was controlled at 35° C., the extraction residence time was 1.5 h, and an extract with a vitamin K2 (MK-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com